Cub Cadet 8404 User Manual

Page 87

ENGINE SYSTEM

2-65

D615-W02 May-2003

615W2D8A

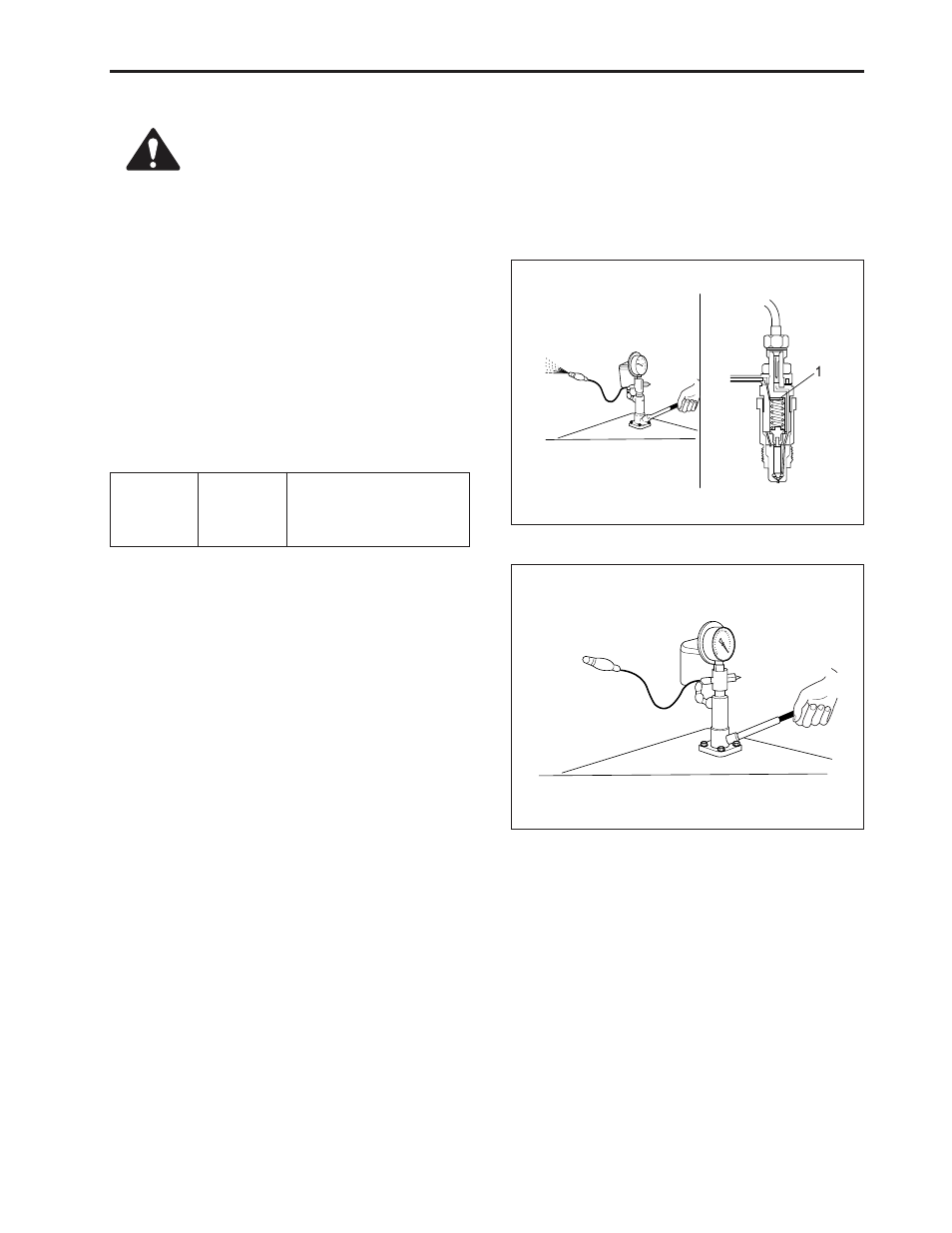

(B) Fuel tightness of needle valve seat tightness

1. Set the injection nozzle to the nozzle tester.

2. Apply a pressure 130 kgf/cm² (12.75 MPa, 1849 psi).

After keeping the nozzle under this pressure for 10

seconds. Check to see if fuel leaks from the nozzle.

3. If the fuel should leak, replace the nozzle.

b. Injection nozzle

Fuel

injection

pressure

Factory

spec.

13.73 ~ 14.71 MPa

140 ~ 150 kgf/cm²

1991 ~ 2134 psi

(1) Adjustment Washer

•

Never contact with spraying diesel fuel

under pressure, pressure, which can

have sufficient force to penetrate the

skin, causing serious personal injury.

•

Be sure nobody is in direction of the

spray.

CAUTION

(A) Fuel injection pressure

1. Set the injection nozzle to the nozzle tester.

2. Measure the injection pressure.

3. If the measurement is not within the factory specifi-

cations, adjust with the adjustment washer (1) in-

side the nozzle holder.

(Reference)

•

Pressure variation with 0.1 mm (0.004 in.) difference

of adjusting washer thickness is approx. 10 kgf/cm².

615W2D9A