Cub Cadet 8404 User Manual

Page 101

CLUTCH

3-13

D615-W02 May-2003

615W324A

615W325A

B. DISASSEMBLY, ASSEMBLY

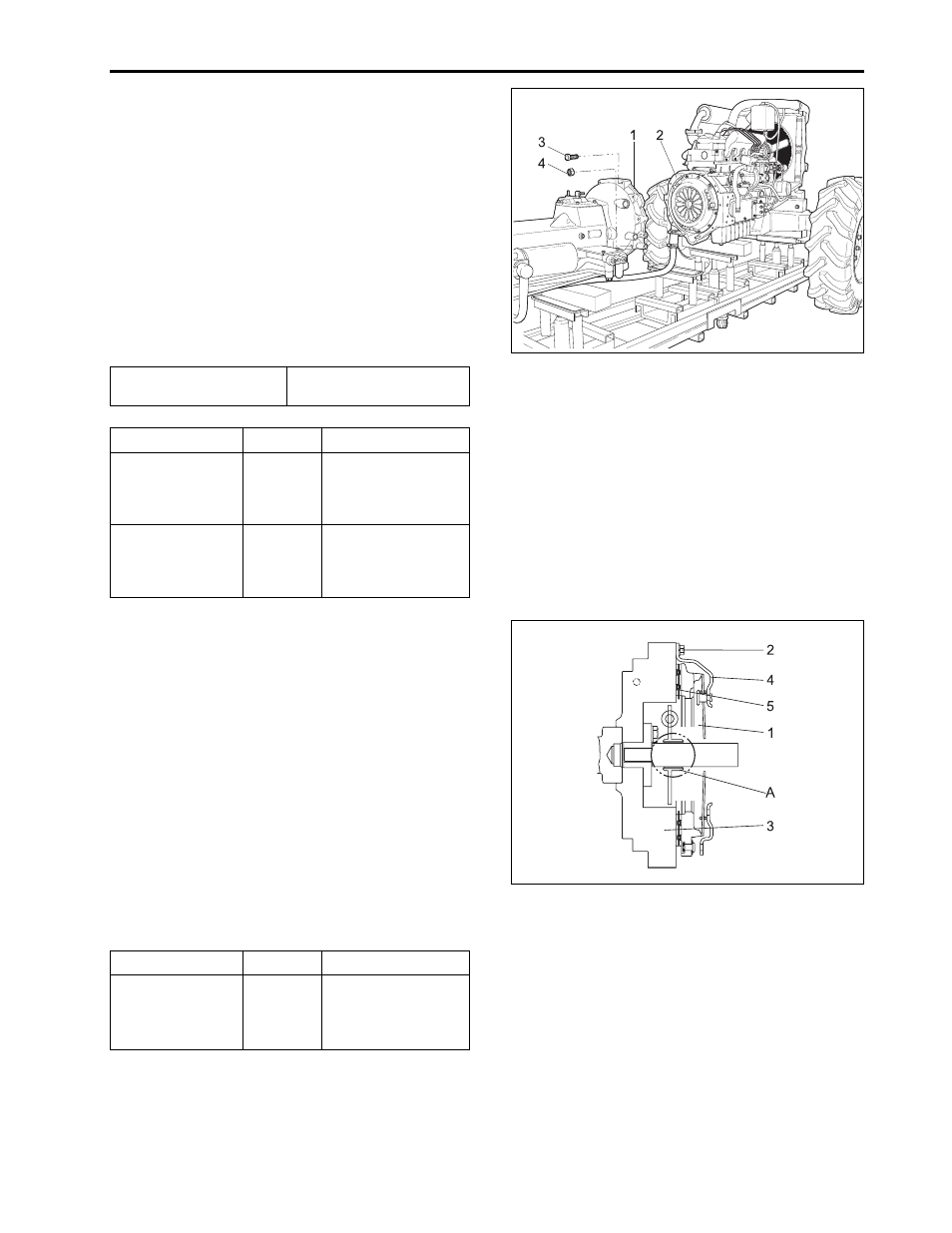

a . First Stage (Disconnection of Clutch Hous-

ing and Flywheel Housing)

1. Support clutch housing (1) and engine with hydrau-

lic jack.

2. Disengage clutch housing (1), flywheel housing (2),

tightening bolt (3) nut (4).

3. Disconnect clutch housing and engine.

(When reassembling)

•

Apply spline with grease.

•

Apply the contacted surface between clutch hous-

ing and flywheel housing with sealing agent.

Sealing agent

Three bond 1208D or

equivalent

b. Second Stage (Disconnection of Clutch

Assembly)

1. Disengage clutch assembly (1), attaching bolt (2)

and disconnect clutch from flywheel (3).

(When reassembling)

•

Take notice that assembly direction and shorter

spline boss (A) should be located toward flywheel

when assembling clutch disc.

•

Take care to treat clutch disc and clean each fiction

surface of flywheel and clutch pressure plate.

IMPORTANT:

•

When attaching the clutch cover (4) and clutch disk

(5) with the flywheel, you should set the clutch disk

(5) in the right position. And then, tight bolt equally

in the diagonal direction.

(1) Clutch Housing

(2) Flywheel Housing

(3) Bolt

(4) Nut

Sect.

Tightening bolt,

nut

Stud

Tightening Torque

77.5 ~ 90.2 N·m

7.9 ~ 9.2 kgf·m

57.2 ~ 66.5 lbf·ft

39.2 ~ 49.0 N·m

4.0 ~ 5.0 kgf·m

28.9 ~ 36.2 lbf·ft

Specified

M12

M12

Sect.

Tightening bolt

Tightening Torque

23.5 ~ 27.5 N·m

2.4 ~ 2.8 kgf·m

17.4 ~ 20.3 lbf·ft

Specified

M8

(1) Clutch Assembly

(4) Clutch Cover

(2) Washer Holding Bolt

(5) Clutch Disc

(3) Flywheel