Cub Cadet 8404 User Manual

Page 30

CHAPTER 2 8354/8404

2-8

D615-W02 May-2003

615W212A

615W211A

615W210A

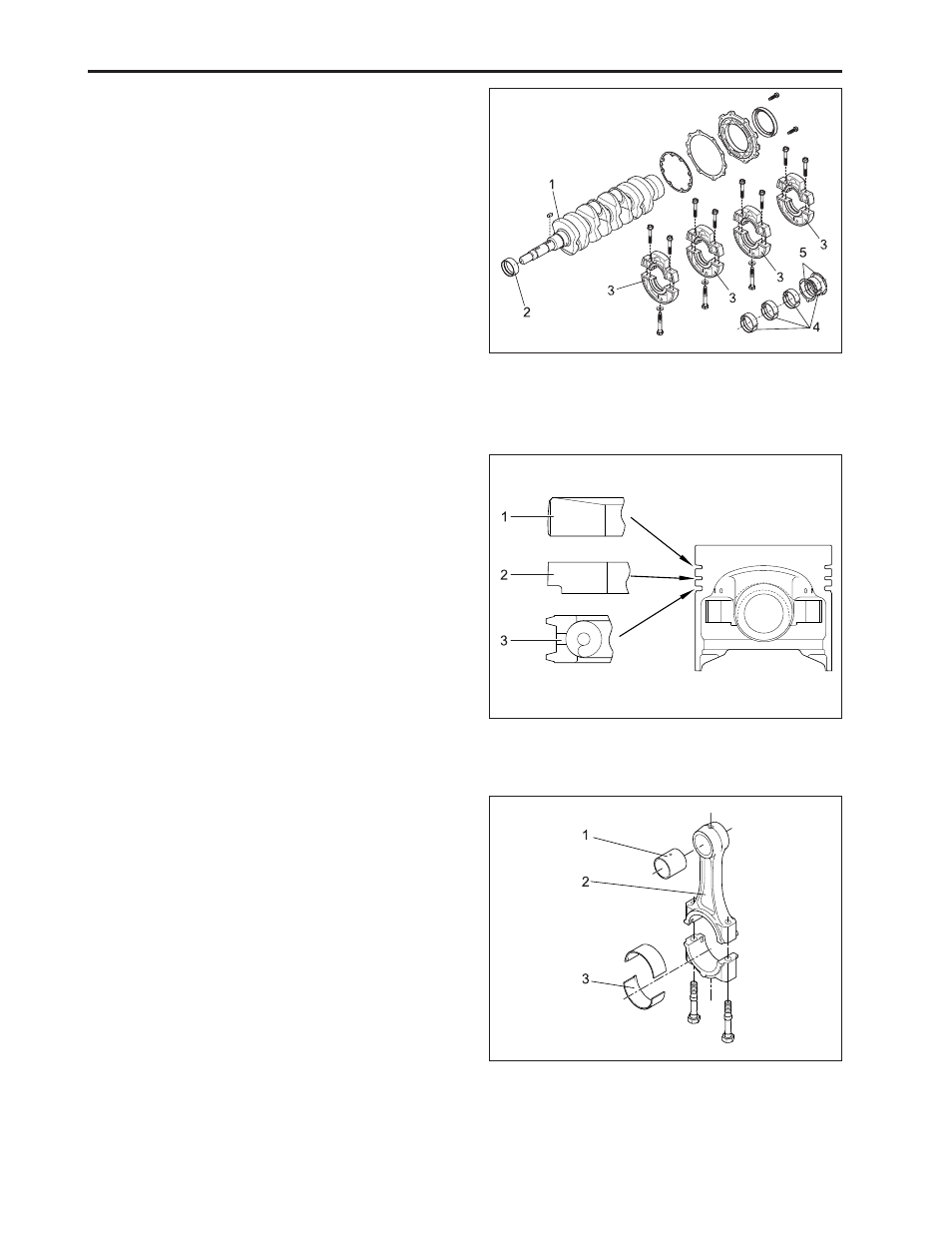

C. CRANKSHAFT

The crankshaft is made of forged steel and the journals,

the crankpins and the bearing surface for the oil seal

are induction-hardened to increase wear resistance.

Each crankshaft journal is supported by the main bear-

ing case (3) having a bearing inside. The front bearing-

crankshaft bearing (2) is a solid type bushing and rear

and intermediate bearings are a split type. The

crankshaft, crankshaft bearings have oil holes for lu-

bricant flow.

D. PISTON AND PISTON RINGS

The piston is made of an aluminum alloy which is tem-

perature and pressure resistant. Three rings are in-

stalled in the grooves of the piston. The top ring (1) is a

keystone type, which can withstand heavy loads, and

the barrel face on the ring fits well to the cylinder wall.

The second ring (2) is an undercut type, which pre-

vents the oil from being carried up. The oil ring (3) has

chambered contact faces and an expander ring, which

increase the pressure of the oil ring against the cylin-

der wall to scrape the oil. The top ring is plated with

hard chrome to increase wear resistance (The ring of

4A200T engine is made of a special steel).

E. CONNECTING ROD

The connecting rod (2), which converts the reciprocat-

ing motion of the pistons caused by the fuel combus-

tion into the rotating motion of the crankshaft, is made

of hard forged steel. The connecting rod has bearings

at both ends. The small end has a solid type bearing

(small end bushing (2)) and the big end has a split

type bearing (crankpin bearing (3)).

(1) Top Ring

(3) Oil Ring

(2) Second Ring

(1) Small End Bushing

(3) Crankpin Bearing

(2) Connecting Rod

(1) Crankshaft (4) Crankshaft Bearing 2

(2) Crankshaft Bearing 1 (5) Thrust Bearing

(3) Main Bearing Case