Cub Cadet 8404 User Manual

Page 204

CHAPTER 7 8354/8404

7-16

D615-W03 May-2003

615W724A

615W725A

Sect.

Spec.

Tightening torque

The attaching bolt of

center pin

M12

77.5 ~ 90.2 N·m

7.9 ~ 9.2 kgf·m

57.2 ~ 66.5 lbf·ft

8.6 SIXTH STAGE (DISASSEMBLY OF

BEVEL PINION SHAFT)

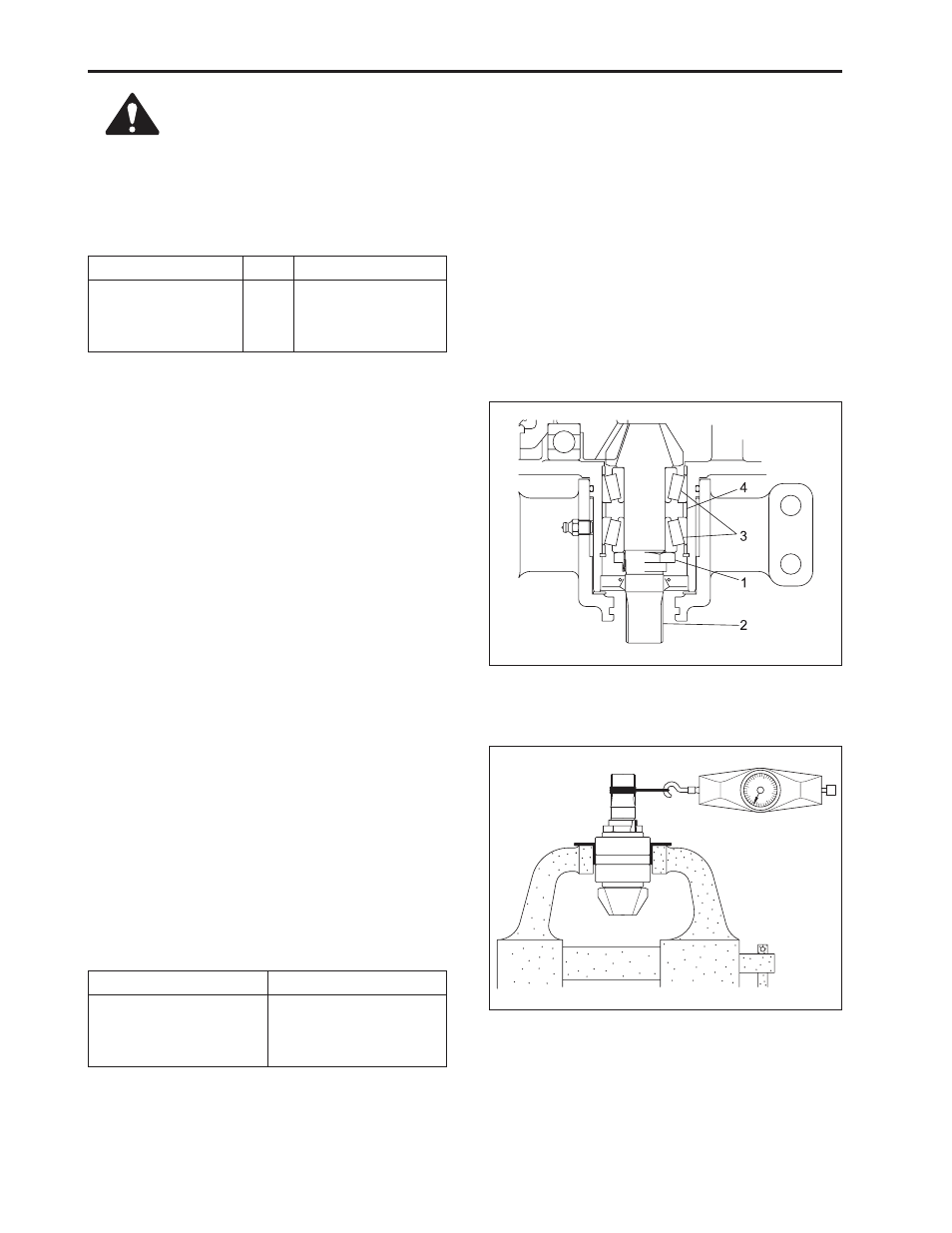

1. Straighten cocking and loosen lock nut (1).

2. Remove taper roller bearing (3) from bevel pinion

shaft (2).

(When reassembling)

•

Make sure taper roller bearing assembly direction

is correct.

IMPORTANT:

•

When tightening lock nut, always check for bearing

backpressure.

(1) Lock Nut

(3) Taper Roller Bearing

(2) Bevel Pinion Shaft

(4) Spacer Barrel

A. How to Check Bearing Backpressure

•

Insert taper roller bearing and spacer barrel (4) into

pinion shaft and tighten lock nut by hand.

•

With bevel pinion shaft into assembly, lock the outer

of bearing into vice.

•

Wrap pinion shaft spline several times using rope,

pull out rope using push-pull gage and check for

rotation torque of pinion shaft.

•

If rotation torque exceeding the spec., loosen lock

nut and if less than the spec., tighten lock nut and

perform cocking so that the nut will not loosen.

Sect.

Specified value

Bevel pinion shaft

rotation torque

0.98 ~ 1.18 N·m

0.1 ~ 0.12 kgf·m

0.72 ~ 0.87 lbf·ft

•

When assembling DX bush (20), (21)

into front and rear brackets, align hole

of DX bush with assembly hole of

grease nipple (19) (See the following

figure).

•

Make sure the oil seal assembly di-

rection of bevel Pinion shaft is correct

(See the following figure).

CAUTION