Fieldbus analog input data manipulation, Fieldbus analog input data manipulation -8 – Rockwell Automation PLC-5 Fieldbus Solutions for Integrated Architecture User Manual User Manual

Page 52

Publication 1757-UM006A-EN-P - May 2002

2-8 Integrating Fieldbus into Rockwell Automation Logix System

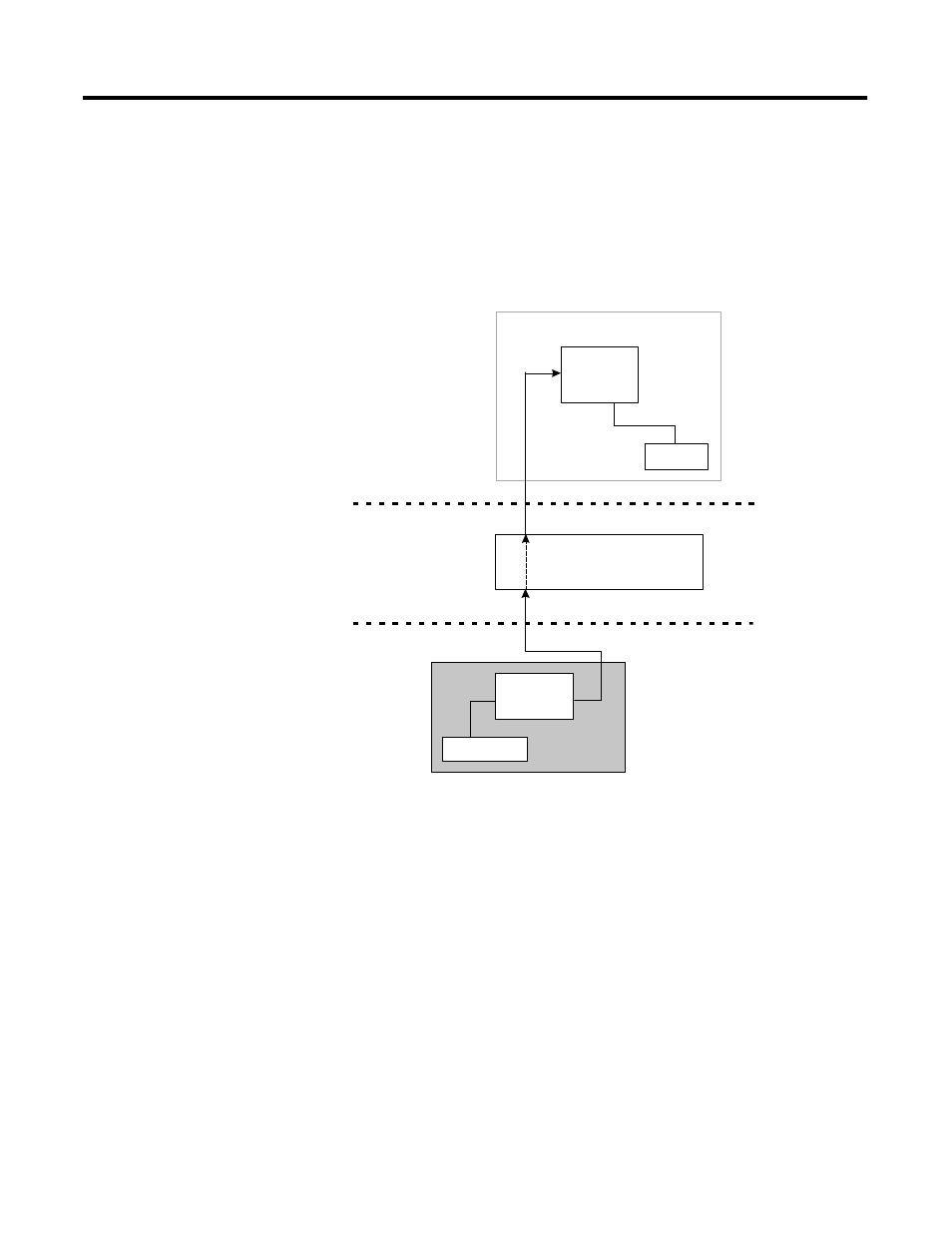

Figure 2.3 shows a simplified functional diagram of how the output

from an Analog Input function block in a fieldbus compliant

transmitter is integrated with a PID function block in a Control Module

that is assigned and loaded to the CEE in the Control Processor

Module (CPM).

Figure 2.3 Integration of fieldbus device analog input signal with ProcessLogix

control strategy

Fieldbus Analog Input data manipulation

When the OUT from the fieldbus analog input function block is wired

to the PV input for a PID function block, the Control Builder creates a

CEE input agent to handle the analog input from the fieldbus block.

The block-like input agent maps the data structure (DS-65) of the

OUT parameter to the ProcessLogix PV with status parameter. It

interprets the value portion in fieldbus terms and converts it to

ProcessLogix representation. The floating-point representation is

identical, in most cases, but the fieldbus +/-infinity value must be

converted to a ProcessLogix representation.

If the fieldbus status byte indicates “BAD”, the value must be

converted to Not a Number (NaN) for ProcessLogix representation.

CM

CPM/CEE

FIM

Fieldbus

Device

FIM

Analog

Input

Transducer

PID

AOC

OUT

PV

OP

OP

AOC = Analog Output Channel

CEE = Control Execution Environment

FIM = Fieldbus Interface Module

OP = Output

PID = Proportional, Integral, Derivative

CM = Control Module

CPM = Control Processor Module

PV = Process Variable