Torque prove setup on – Rockwell Automation 23P PowerFlex Digital DC Drive User Manual

Page 294

294

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Appendix C

Application Notes

Torque Prove Setup

Carefully perform the following steps in the order presented.

1.

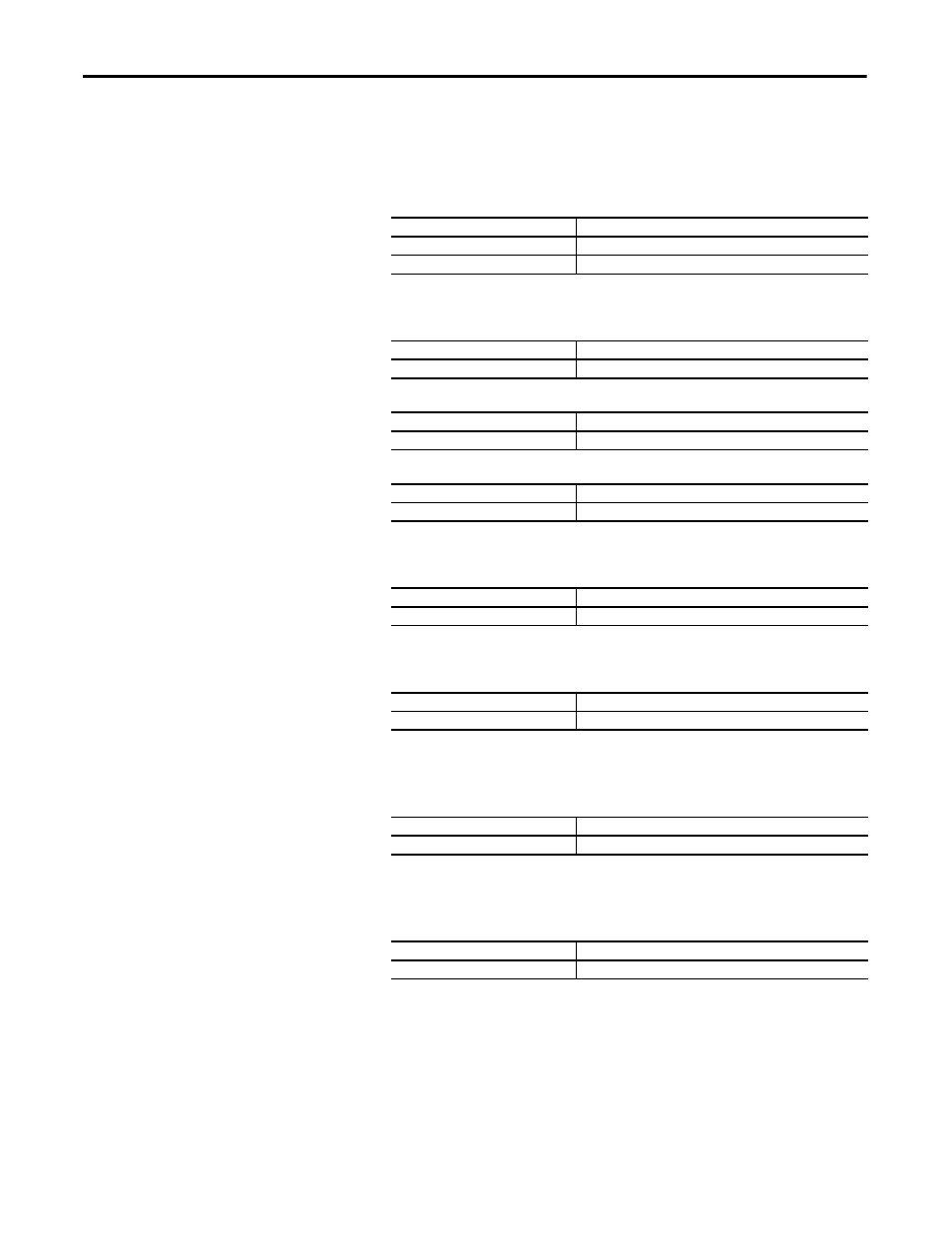

Enter the Torque Prove parameter settings.

Once Torque Prove is activated the drive is in alarm state.

2.

Select the source of speed feedback.

3.

Set the time to decrease motor torque during the Brake Slip test.

4.

Set the speed deviation.

Increase this setting if the drive faults on F94 “TorqPrv Spd Band.”

5.

Set the speed deviation level.

Increase this setting if the drive faults on F94 “TorqPrv Spd Band.”

6.

Set the brake release time.

Increase or decrease this setting depending on the time required to open

the brake.

7.

Set the brake set time.

Increase or decrease this setting depending on the time required to close

the brake.

8.

Set the allowable brake slip.

Sets the number of motor revolutions the motor is allowed to lower the

load when a brake slip has been detected.

Parameter

Setting

629 [Relay Out 2 Sel]

“TP Brake Cmd” (31)

1100 [Torq Prove Cfg]

Bit 0 “TP Enable” = 1

Parameter

Setting

414 [Fdbk Device Type]

“Encoder” (1) - Verify that P169 [Encoder PPR] is set correctly.

Drive Parameter

Setting

1104 [Torq Limit Slew]

10.000 Secs (Default)

Parameter

Setting

1105 [Speed Dev Band]

52.50 RPM (Default)

Parameter

Setting

1106 [SpdBand Intgrtr]

60 ms (Default)

Parameter

Setting

1107 [Brk Release Time]

100 ms (Default)

Parameter

Setting

1108 [Brk Set Time]

100 ms (Default)

Parameter

Setting

1109 [Brk Alarm Travel]

1.00 (Default)