Rockwell Automation 23P PowerFlex Digital DC Drive User Manual

Page 290

290

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

Appendix C

Application Notes

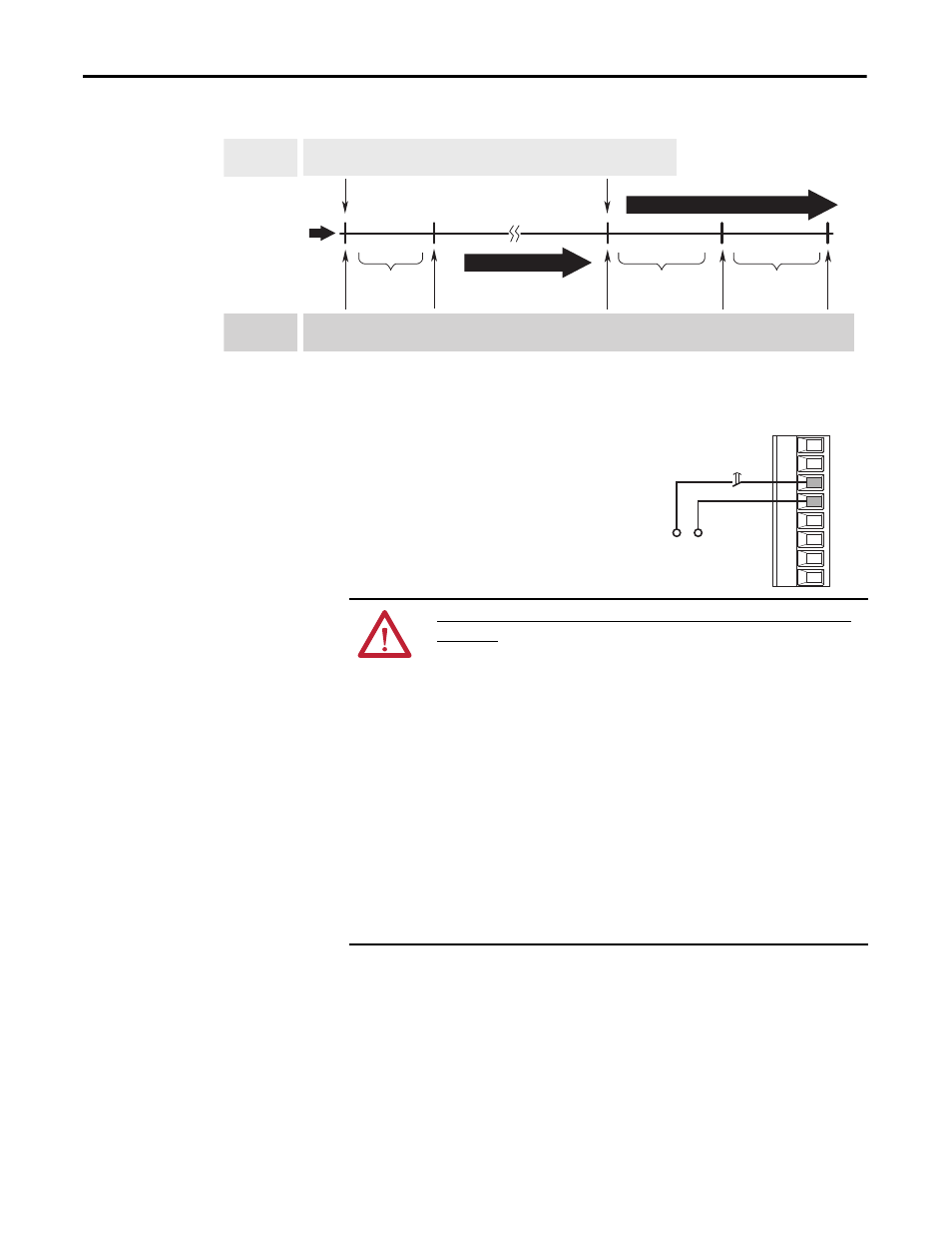

Figure 86 - Torque Proving Flow Diagram

(1) For torque proving to function properly, a mechanical brake must be

wired to a relay output.

Torque

Prove Initiated

Brake

Released

Float

Initiated

Brake

(1)

Set

Brake

Slip Test

Run

Command

Run

Command Released

Drive Running

Run can be initiated anytime

All times between Drive Actions are programmable and can be made very small

(i.e. Brake Release Time can be 0.1 seconds)

[ZeroSpdFloatTime]

Parameter 1113

[Brk Release Time]

Parameter 1107

[Brk Set Time]

Parameter 1108

Operator

Commands

Time

Drive

Actions

ATTENTION: User must read the following prior to the use of TorqProve without

an encoder.

Encoderless TorqProve must be limited to lifting applications where personal safety

is not a concern. Encoders offer additional protection and must be used where

personal safety is a concern. Encoderless TorqProve cannot hold a load at zero

speed without a mechanical brake and does not offer additional protection if the

brake slips/fails. Loss of control in suspended load applications can cause personal

injury and/or equipment damage.

It is the responsibility of the engineer and/or user to configure drive parameters,

test any lifting functionality and meet safety requirements in accordance with all

applicable codes and standards. If encoderless TorqProve is desired, the user must

certify the safety of the application. To acknowledge that the end user has read this

“Attention” and properly certified their encoderless application, parameter 414

[Fdbk Device Type] must be changed to “DC Tach” (2). This will allow bit 1 of

parameter 1100 [Torq Prove Cfg] to be changed to a “1” without causing a Type 2

alarm when lifting/torque proving is enabled (Par 1100, bit 0 = 1).

Control

Voltage

78

79

35

36

75

76

U2

V2

Brake

Relay