Rockwell Automation 23P PowerFlex Digital DC Drive User Manual

Page 219

Rockwell Automation Publication 20P-UM001K-EN-P - July 2014

219

Troubleshooting

Chapter 4

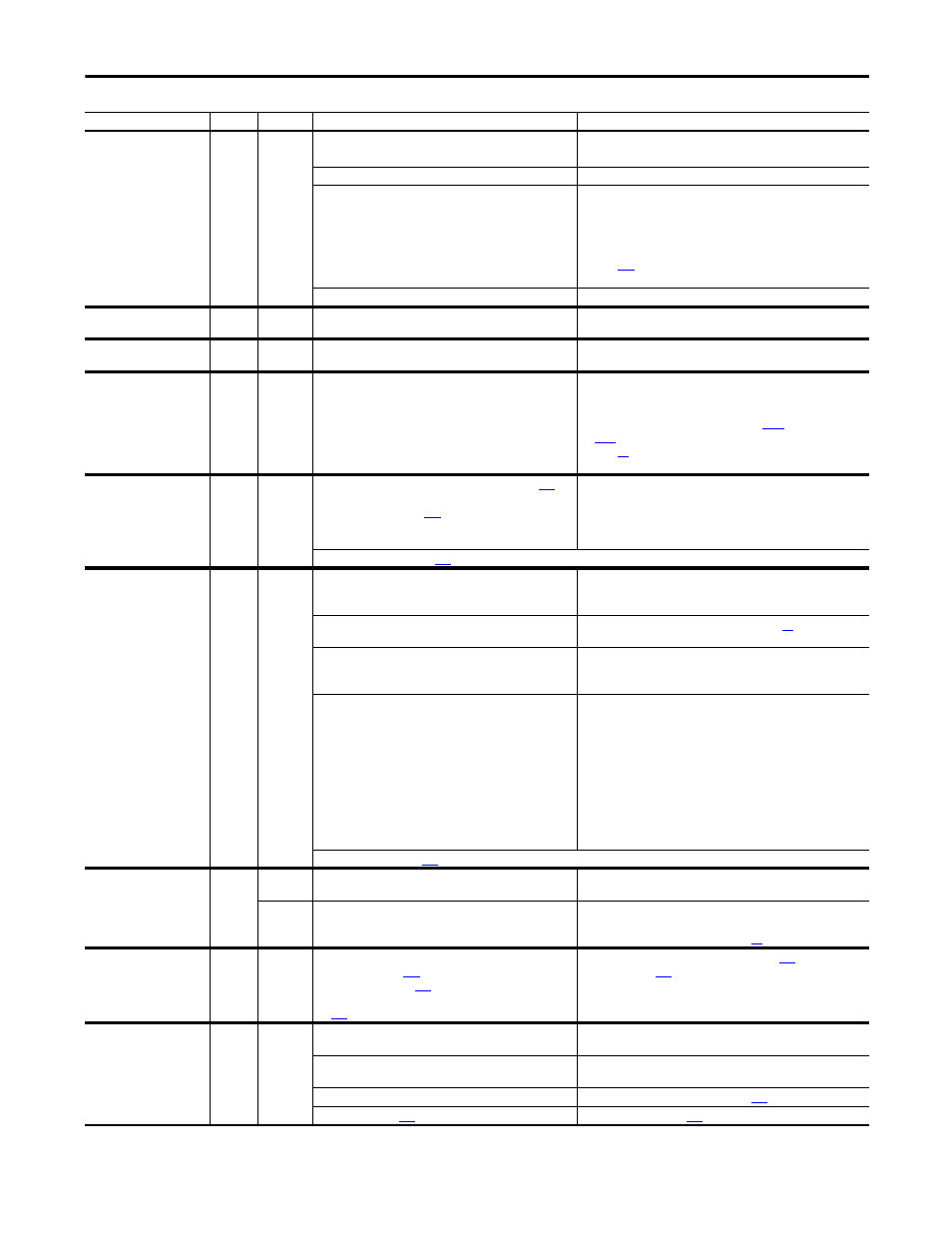

Heatsink OvrTemp

8

2

The heatsink temperature is too high

Possible causes include:

• The surrounding air temperature is too high.

Lower the surrounding air temperature.

• The drive’s cooling fans have failed (drives > 110 A).

Check the fan fuses and fans.

• If the fan fuses have failed, replace the fuses. (The fans are

protected by the fuses in the power supply circuit and are

contained on the switching power supply circuit board in frame

A and B drives only. See Control Power Circuit Protection Fuses on

page

• If the fans have failed, replace the fans.

• The heatsink is dirty.

Clean the heatsink.

Interrupt Error

131

2

A non-resettable software error has occurred in the main

application.

Report this error to the manufacturer.

Inverting Fault

37

2

A digital input (Pars 133…144) configured as 64 “Invert Flt”

has been removed.

Check the status of the inverting fault device connected to the

digital input.

Main Contactor

10

2

One of the following has occurred:

• The Main and/or Dynamic Brake (DB) contactor failed to

open or close in the proper amount of time (920 ms).

• A digital input and/or relay output 1 is incorrectly wired

and/or configured.

• Wiring to a digital input configured for contactor has

opened.

• Check all contactor wiring and drive jumpers. Repair or replace

the contactor(s) if the problem(s) persist.

• Check the digital input and/or relay output 1 (terminals 35 and

36) wiring and configuration using Pars

[ContactorControl],

[Relay Out 1 Sel] and [Digital Inx Sel]. See Contactors on

for more information.

Motor Overload

7

1

The selected motor overload current level (set in Par

[Nom Mtr Arm Amps]) has been exceeded. The limits are

based on the value of Par

[MtrOvrld Type]. 0

“StandardDuty” is 150% for 60 sec. or 200% for 3 sec. 1

“HeavyDuty” is 200% for 1 minute (250% for 30 sec).

Reduce the motor load, current limits, and/or ramp times.

Note: Configurable with Par

[MtrOvrld Flt Cfg].

Motor Over Temp

16

1

The motor has exceeded its temperature rating (as signaled

by the thermistor connected to the drive terminals 78 and

79). Possible causes include:

• The motor does not have a thermistor and there is no

resistor between terminals 78 and 79 on the drive.

See Thermistors and Thermal Switches on page

for configuration

information.

• The cable between the thermistor connection on the

motor and terminals 78 and 79 on the drive has been

broken.

Check and repair any damage to or loss of connection of the

thermistor cables between the motor and drive.

• The overheating of the motor may have been caused by

one of the following:

• The Load cycle is too extreme.

• The surrounding air temperature at the site of motor is

too high.

• The motor has an external fan and the fan failed.

• The motor does not have an external fan and the load is

too large at low speeds. The cooling effect of the

internal fan on the motor shaft is too low for this load

cycle.

Reduce the load.

Reduce the surrounding air temperature.

Replace the motor fan.

Reduce the load cycle or fit the motor with an external fan.

Note: Configure with Par

[OverTemp Flt Cfg].

No Fault

0

–

When present in the fault queue in the drive only, this fault

indicates that there are currently no faults in the drive.

Informational only.

2

When displayed on the HIM, this fault indicates that the

SA-SB terminal on a frame B or C drive is incorrectly

configured.

For frame B or C drives only, verify that terminal SA-SB is properly

configured for the control circuit input power input voltage used.

See Control Circuit Input Power on page

Open SCR

90

1

An open SCR fault condition has been detected. This fault can

only occur when Par

[SCR Diag Test En], bit 0 “OpenSCR

Tst” is set (=1) and Par

[OpenSCR Flt Cfg] is set to “Fault”

(2). The SCR (or SCR pair) that caused the fault are shown in

Par

[SCR Diag Status].

• Verify that the correct values are set in Pars

[Open SCR

[OpenSCR Trip Lvl].

• Replace the failed SCR device(s).

Overcurrent

13

1

An overcurrent has occurred in the motor circuit. Possible

causes include:

• There is a short-circuit or ground fault at the output of the

drive.

Verify the armature circuit wiring is correct.

• The current regulator was not properly fine tuned.

See Tune the Current Regulator on page

.

• The value of Par

[OverCurrent Thr] is too low.

Increase the value of Par

[OverCurrent Thr] accordingly.

Fault Name

Number Type

(1)

Description/Possible Cause(s)

Action(s)