2 machine modules (mm), Machine modules (mm), What is the applicationtemplate – Lenze PLC Designer ApplicationTemplate (PLC Designer R3-x) User Manual

Page 18

What is the ApplicationTemplate?

Elements of the ApplicationTemplate

18

Lenze · ApplicationTemplate · 1.3 EN - 04/2013

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3.2

Machine modules (MM)

The overall functionality of the automation system is structured in a modular manner in the

ApplicationTemplate. This means that every subfunction of the machine is included in one of the

machine modules. Due to the modular structure, individual (or multiple) subfunctions of a machine

can be reused. Advantage: The respective function does not have to be recreated for further

machine parts.

• A machine module represents the function of a machine part; for instance a conveying belt, or

a cross cutter.

• The overall functionality of, for example, a bag form, fill, and seal machine, contains the "Cross

cutter" and "Transport unit" subfunctions. The two subfunctions are to be converted to a

separate machine module each.

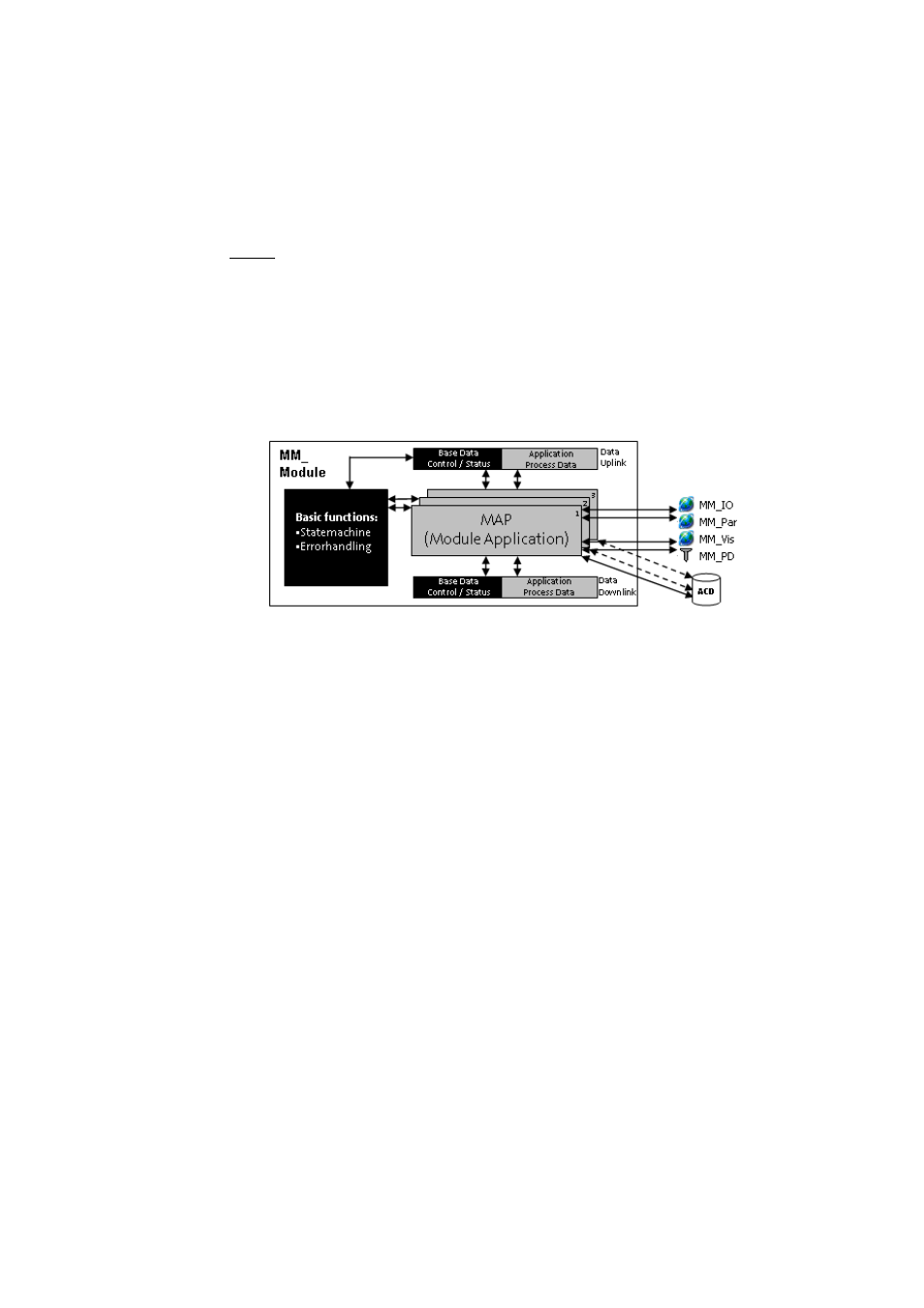

Machine module in the ApplicationTemplate

[4-3]

Structure of a machine module

• Every machine module contains the BaseChannel ("Base Data") which serves as a data

channel for the basic functions of the ApplicationTemplate.

• The basic functions of the ApplicationTemplate are the State machine and the Error handling.

Every machine module has an AppChannelData structure (ACD structure). An ACD structure can be

defined in a machine module if necessary.

• Via the ACD structure, data are provided to/received from the higher-level machine module.

• Via the ACD structure, process data can be exchanged between the user's own module

applications.

A machine module (MFB) always contains at least one module application (MAP). Up to three MAPs

per MFB are possible.

• Via the MM_IO, MM_Par; MM_Vis, MM_PD structures, the module application (MAP) is to be

connected to the "outside world" (the respective sub-function of the automation system).

• By means of the MM_IO structure, the inputs/outputs of the terminals/the fieldbus are to be

connected.

• The MM_Par structure contains all variables that are to be managed by the recipe manager.

• The MM_Vis structure contains all variables that can be controlled or are to be displayed via an

external visualization.

• The MM_PD structure contains all persistent variables.