SkyTrak 6036 Service Manual User Manual

Page 64

Boom

3.24

Model 6036 Legacy

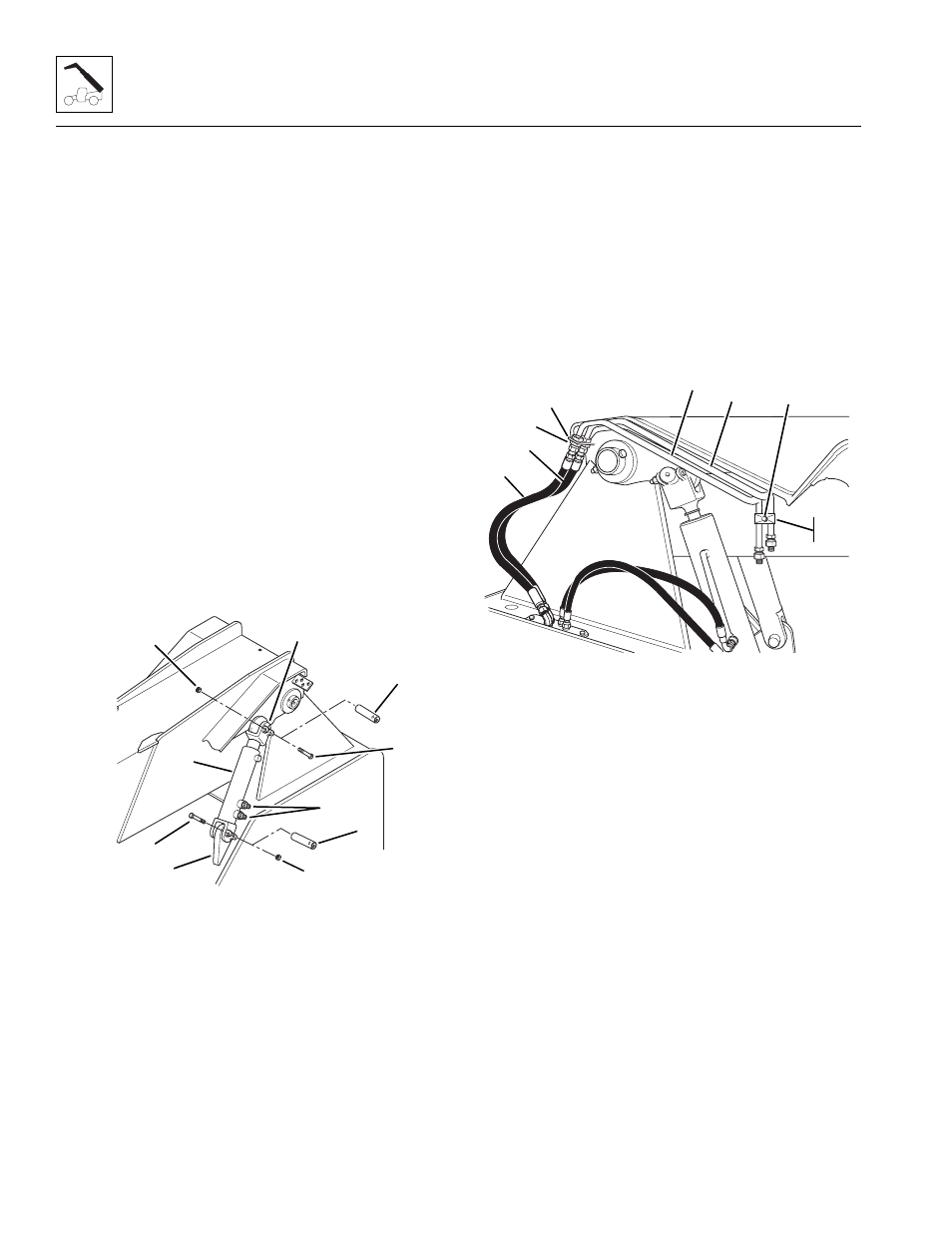

19. Use a hoist and sling to position the slave cylinder

(Fig. 3-54, 1) onto the lower cylinder mount (2)

located on the frame. The cylinder should be

positioned with the port fittings (3) toward the outside.

20. Coat the lower pivot pin (Fig. 3-54, 4) with anti-seize

compound. Insert the pin through the base end of

the slave cylinder. Use a tapered punch to line up

the capscrew hole in the pin with the mounting tabs

on the cylinder. Secure the lower pivot pin in place

with the capscrew (5) and a new 1/2-13 elastic

locknut (6). Tighten the elastic locknut securely.

21. Position the rod end of the slave cylinder (Fig. 3-54, 7)

around the self-aligning bearing on the outer boom.

22. Coat the upper pivot pin (Fig. 3-54, 8) with anti-seize

compound. Insert the pin through the rod end of the

slave cylinder. If necessary, use a rawhide hammer

to install the upper pivot pin. Use a tapered punch to

align the capscrew hole in the pin with the mounting

tabs on the cylinder. Secure the upper pivot pin in

place with the capscrew (9) and a new 1/2-13 elastic

locknut (10). Tighten the elastic locknut securely.

23. Repeat Steps 19-22 to install the other slave cylinder

on the other side of the outer boom.

Figure 3- 54 Install the Slave Cylinder

Note: ALWAYS use new o-rings when servicing the

vehicle.

24. Install new o-rings into the fittings. Lubricate o-rings

with clean hydraulic oil.

25. Install the extend (Fig. 3-55, 1) and retract (2) tubes

to the mounting plate (3). Secure the tubes to the

mounting plate with bulkhead nuts (4).

26. Install the tube clamp halves (Fig. 3-55, 5) to the

extend (1) and retract (2) tubes. Place one clamp

half on top of the tubes and one on the underside of

the tubes. Place a clamp cover (6) on the top and

bottom of the clamps. Secure in place with the

5/16-18 x 2" capscrew and flat washer (7). Position

the clamp halves to securely hold the tubes without

putting tension on either tube.

27. Connect the extend (Fig. 3-55, 8) and retract (9)

hoses to the tubes at the mounting plate (3). Tighten

the connections.

Figure 3-55 Install the Extend and Retract Tubes

Note: ALWAYS use new o-rings when servicing the

vehicle.

28. Install new o-rings into the fittings. Lubricate o-rings

with clean hydraulic oil.

29. Remove the plugs and caps from the hoses and

fittings, and loosely connect the extend (Fig. 3-56, 1)

and retract (2) hoses to the extend and retract tubes

(3 and 4).

30. Remove the plugs and caps from the hoses and

fittings, and loosely connect the extend (Fig. 3-56, 1)

and retract (2) hoses to the 90° elbow fittings at the

rear of the extend/retract cylinder (5).

31. Remove any twists from the hoses, and tighten the

connections.

MA6460

1

2

3

6

4

5

7

8

10

9

MA6880

1

2

3

4

7

6

5

8

9