SkyTrak 6036 Service Manual User Manual

Page 328

Hydraulic System

8.112

Model 6036 Legacy

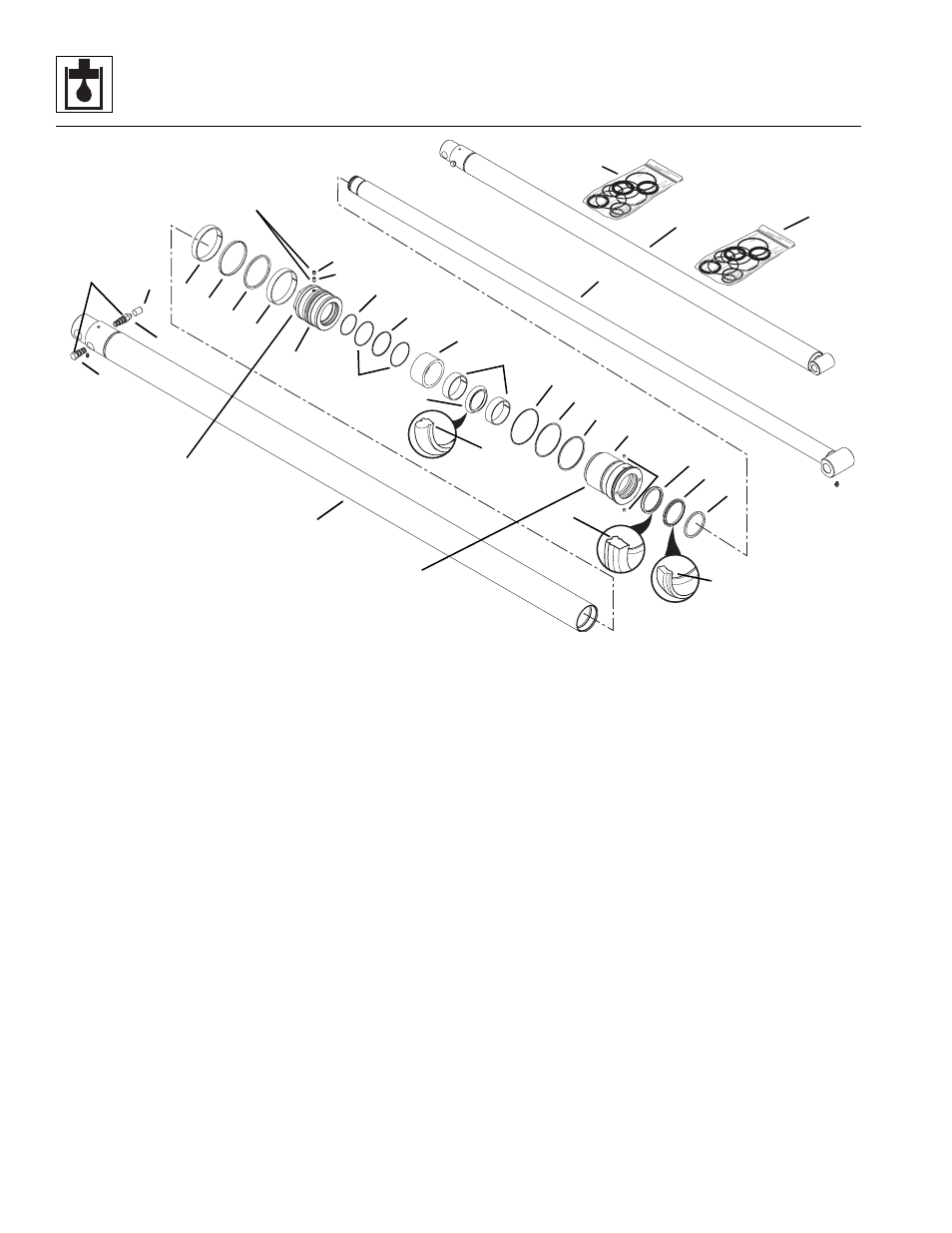

Figure 8-73 Extend/Retract Cylinder Components

e. Extend/Retract Cylinder Assembly

Note: Follow Section 8.13.3, “General Cylinder

Assembly Instructions.”

1. Install a new small oiled o-ring (Fig. 8-73, 18), new

back-up ring (16), oiled o-ring (17) and another back-

up ring (16) into the piston (8).

2. Install the square ring (Fig. 8-73, 15), the piston seal

(14) and both precision wearbands (13) onto the

piston (8).

3. Install the precision wearbands (Fig. 8-73, 22) and

the buffer seal (29), if used, into the front end of the

head gland (7). Orientate the buffer seal as shown

(30). At the rear of the head gland, install the U-cup

seal (25) orienting the edge (27). Install the sealed

outside diameter heavy-duty rod wiper (24). The

wiper lip (28) should be toward the outer end of the

head gland and the seal lips toward the inner end of

the head gland. Use tools that will not damage the

seals. Install the square ring (23).

4. Install a new oiled o-ring (Fig. 8-73, 21), back-up ring

(20) and oiled o-ring (19) onto the head gland (7).

5. Fasten the rear of the rod in a soft-jawed vise and

put a padded support below and near the threaded

end of the rod to help prevent damage to the rod.

6. Carefully slide the head gland (Fig. 8-73, 7), then

the rod spacer (12) onto the rod (6).

7. Carefully slide the piston (Fig. 8 -73, 8) onto the

rod spacer (12) and rod (6). Apply Loctite

Threadlocker #241 to the piston and torque the

piston to 300-400 lb/ft (407-542 Nm).

8. Apply Loctite Threadlocker #241 to the setscrews

(Fig. 8-73, 10 and 11) and thread the first setscrew

(11) and then the second (10) into the piston (8).

Torque the setscrews to 155-165 lb/in (18-19 Nm).

9. Install new locking inserts (Fig. 8-73, 9) into the

holes in the head gland threads.

IMPORTANT: Avoid using excess force when clamping

the cylinder in a vise. Apply only enough force to hold the

cylinder securely. Excessive force can damage the cylinder.

10. Secure the extend/retract cylinder in a soft-jawed

vise or other acceptable holding equipment if

possible.

MA7090

1

2

3

4

5

6

7

8

9

10

11

12

18

19

20

16

17

21

Torque to

300-400 lb/ft

(407-542 Nm)

Apply Loctite

#241 to threads

and torque to

300-400 lb/ft

(407-542 Nm)

25

23

Apply Loctite #241 to

threads and torque to

155-165 lb/in (18-19 Nm)

22

24

28

27

Torque to

45-50 lb/ft

(61-68 Nm)

26

25

13

14

15

13

29

30