Warning – SkyTrak 6036 Service Manual User Manual

Page 340

Hydraulic System

8.124

Model 6036 Legacy

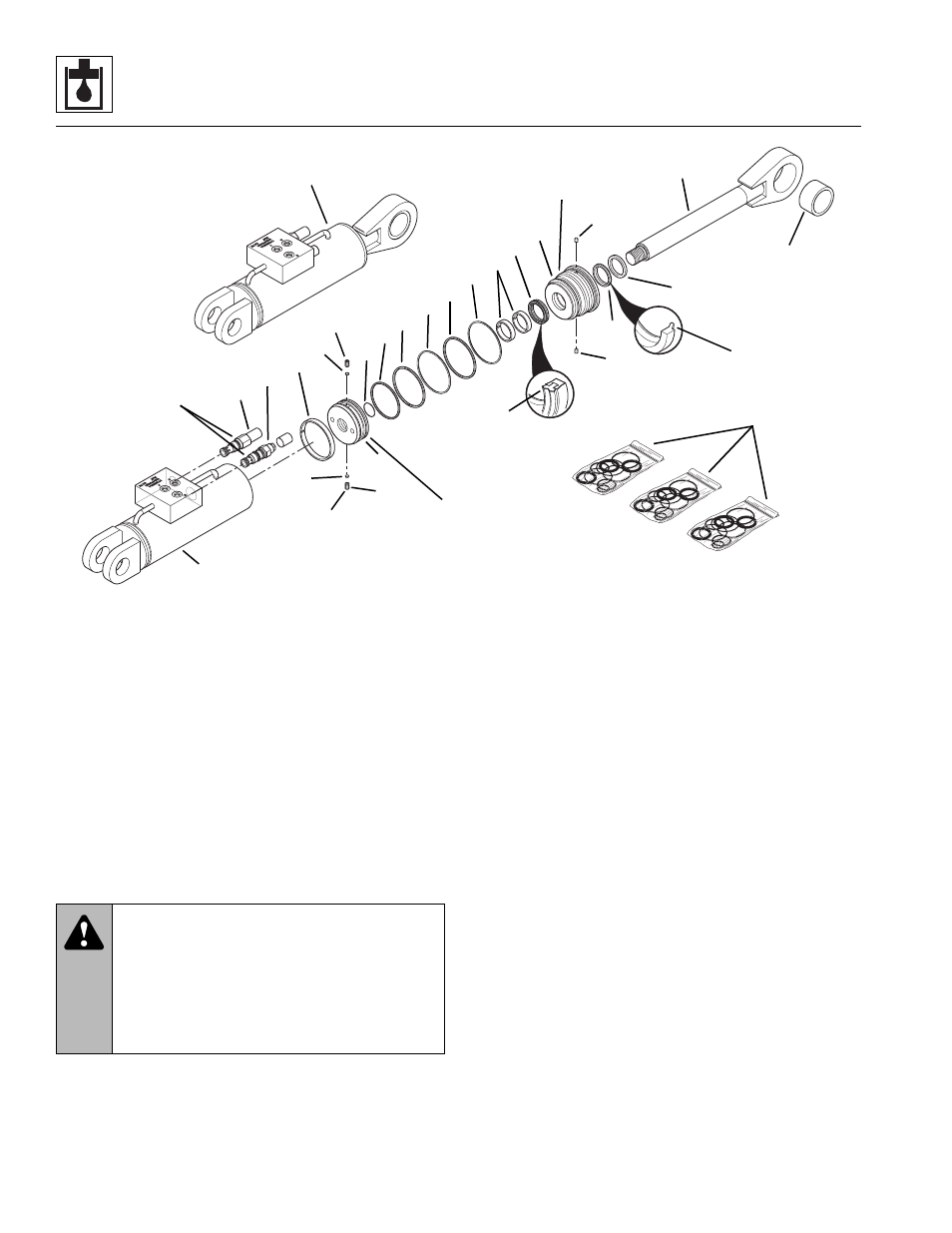

Figure 8- 83 Swing Carriage Cylinder Components (Optional)

b. Swing Carriage Cylinder Disassembly

Note: An additional o-ring may be included at the base

of the cylinder rod. This additional o-ring may be discarded,

as it served only in a temporarily protective role.

1. Clean the swing carriage cylinder (Fig. 8-83, 1) with

a suitable cleaner to remove dirt, debris, grease, etc.

IMPORTANT: Avoid using excess force when clamping

the cylinder in a vise. Apply only enough force to hold the

cylinder securely. Excessive force can damage the

cylinder.

2. Secure the swing carriage cylinder in a soft-jawed

vise or other acceptable holding equipment if possible.

3. Slowly remove the 3000 psi (207 bar) counterbalance

cartridge (Fig. 8-83, 2) and the 2000 psi (138 bar)

direct-acting relief valve (3) from the swing carriage

cylinder.

4. If the self-aligning bearing (Fig. 8-83, 23) requires

replacement, support the rod (4) in a soft-jawed vise

or other suitable holding device. Carefully press the

bearing out of the rod eyelet.

5. Extend the rod (Fig. 8-83, 4) to access the cylinder

base.

IMPORTANT: Protect the finish on the rod at all times.

Damage to the surface of the rod can cause seal failure.

6. Using a pin spanner wrench, unscrew the head

gland (Fig. 8-83, 5) from the cylinder tube (6). The

head gland was originally torqued to 250-300 lb/ft

(339-407 Nm), so a considerable amount of force is

required. Carefully slide the head gland down along

the rod toward the eyelet, away from the tube (6).

IMPORTANT: When sliding the rod and piston assembly

into the tube, prevent the threaded end of the tube from

damaging the piston (Fig. 8-83, 7). Keep the rod centered

within the tube to help prevent binding.

7. Carefully pull the rod (Fig. 8-83, 4) with all

attachments straight out of the tube (6).

8. Fasten the rod end in a soft-jawed vise and put a

padded support below and near the threaded end of

the rod to help prevent damage to the rod.

MT1910

Apply Loctite #242 to

threads and torque to

85-95 lb/ft

(115-124 Nm)

Torque to

35-40 lb/ft

(47-54 Nm)

1

Apply Loctite #271 to

threads and torque to

440-500 lb/ft

(597-678 Nm)

22

4

20

21

14

7

8

9

6

3

2

12

9

8

13

11

10

15

16

17

18

19

5

14

Torque to

250-300 lb/ft

(339-407 Nm)

23

24

25

WARNING:

Significant pressure may be

trapped inside the cylinder. Exercise caution

when removing a counterbalance valve or a

pilot-operated check valve from a cylinder.

Escaping hydraulic fluid under pressure can

penetrate the skin, causing death or serious

injury.