SkyTrak 6036 Service Manual User Manual

Page 336

Hydraulic System

8.120

Model 6036 Legacy

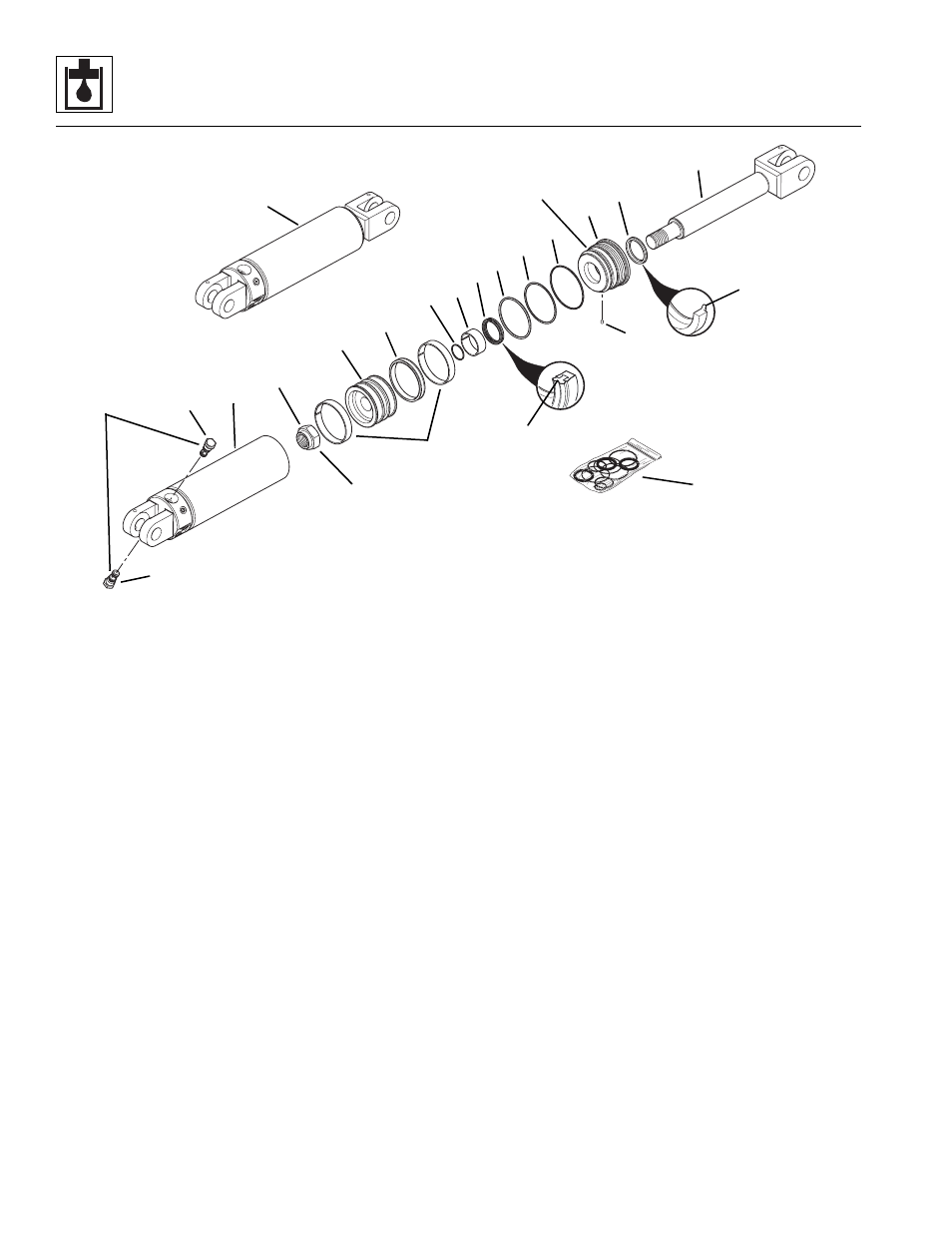

Figure 8-79 Frame Sway Cylinder Components

IMPORTANT: When sliding the rod and piston assembly

into the tube, DO NOT damage the piston by scraping it

against the threads in the tube. Keep the rod in line with

the tube to prevent binding.

6. Carefully withdraw the rod (Fig. 8-79, 6) straight out of

the tube (5). Keep the rod straight during withdrawal to

help avoid scratching, nicking or damaging the tube (5).

7. Secure the rod eyelet and remove the locknut

(Fig. 8-79, 7) from the threaded end of the rod.

Discard the nut; a new nut will be required for

reassembly.

Note: Heating the nut (Fig. 8-79, 7) to approximately

300° F (150° C) may also be required to break the seal

formed by the Loctite Threadlocker #271 (red) applied to

the nut when installed. The application of significant

force is required to overcome the 1100-1250 lb/ft

(1492-1695 Nm) of torque the nut was tightened to when

originally installed.

8. Remove the piston (Fig. 8-79, 8) from the rod (6).

9. Remove the small o-ring (Fig. 8-79, 9) from the

piston (8).

10. Remove the head gland (Fig. 8-79, 4) from the rod (6).

11. Remove both precision wearbands (Fig. 8-79, 10)

from the piston (8).

12. Remove the capped T-seal (Fig. 8-79, 11) from the

piston (8).

Note: The T-seal actually consists of four components: a

wide, flexible inner band, the flexible T-seal band itself,

and two supportive split caps that mount on either side of

the “T” seal band.

13. Remove the o-ring (Fig. 8-79, 12), the back-up ring

(13) and the o-ring (14) from the head gland (4).

14. Remove the heavy-duty rod wiper (Fig. 8-79, 15)

from the head gland (4).

15. Remove the precision wearband (Fig. 8-79, 16) and

deep Z-seal with rod back-up (17) from inside the

head gland (4).

c. Frame Sway Cylinder Internal Cleaning

1. Remove all hydraulic fluid, dirt and debris from the

inner surface of the cylinder.

2. Discard all seals, back-up rings and o-rings. Replace

with new items from a complete seal kit (Fig. 8-79, 18)

to help ensure proper cylinder function.

3. Clean all metal parts with an approved cleaning

solvent such as trichlorethylene. Carefully clean

cavities, grooves, threads, etc.

MT1900

Apply Loctite #271 to

threads and torque to

1100-1250 lb/ft

(1492-1695 Nm)

7

8

14

13

12

17

16

9

11

1

4

15

5

2

2

10

3

18

6

Torque to

35-40 lb/ft

(47-54 Nm)

Torque to

300-400 lb/ft

(407-542 Nm)

19

20