Warning – SkyTrak 6036 Service Manual User Manual

Page 48

Boom

3.8

Model 6036 Legacy

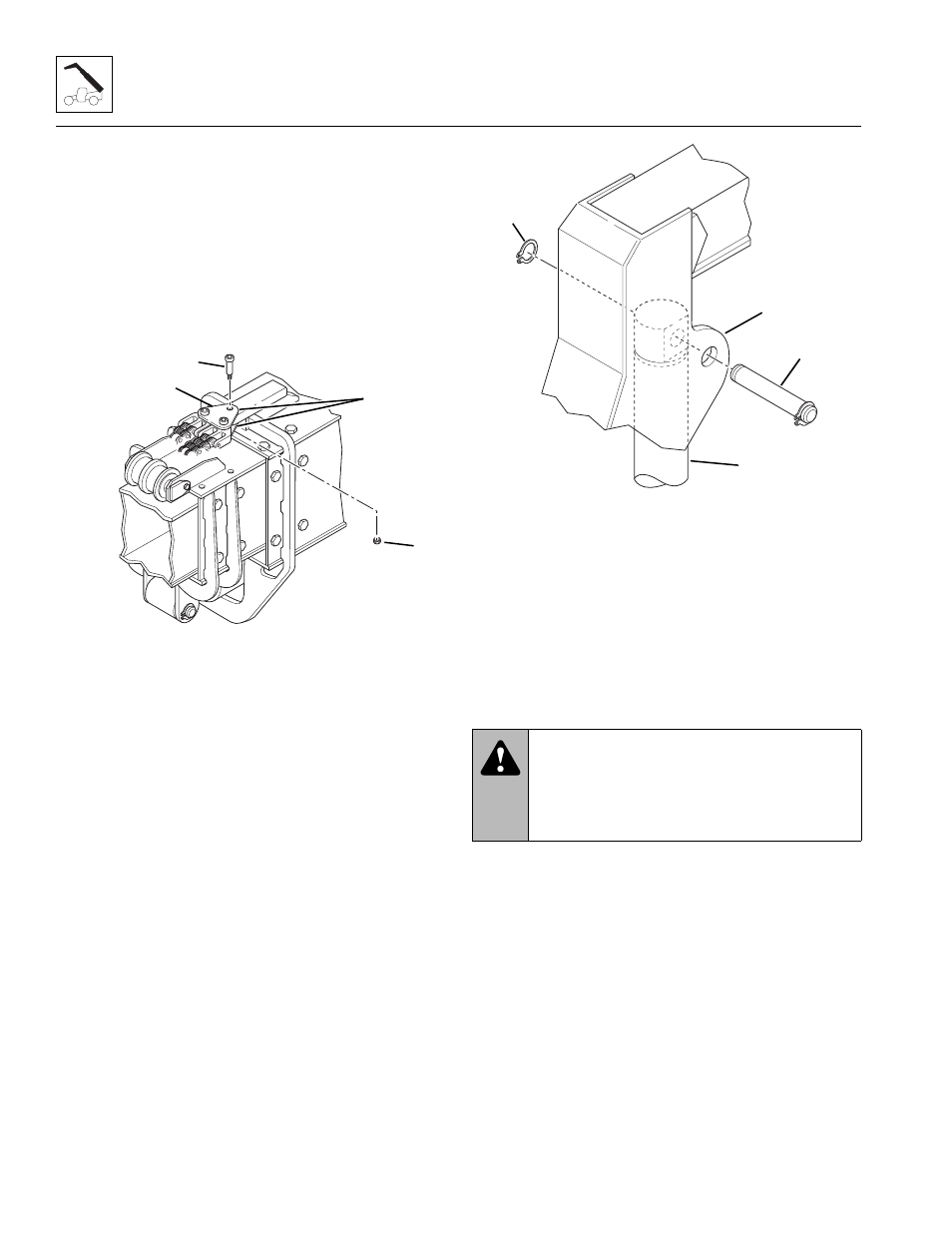

18. Remove the elastic locknut (Fig. 3-11, 1) and

shoulder bolt (2) holding the two yoke plates (3) to

disconnect the extend chain yoke (4) from the outer

boom. Retain the shoulder bolt and discard the

elastic locknut. Lay the chain assembly flat against

the inner boom.

19. Inspect the yoke plates for wear or distortion. If any

wear or distortion is detected, both plates must be

replaced. If no wear is detected, the plates can

remain assembled to the extend chain clevis’.

Figure 3-11 Disconnect the Extend Chain

Note: If replacing the inner boom assembly with a new

inner boom, the quick attach assembly and the

attachment tilt cylinder should be removed at this time. If

the inner boom is not to be replaced, the quick attach

assembly and attachment tilt cylinder can remain in place.

20. Remove the quick attach assembly. (Refer to Section

3.4.3, “Quick Attach Removal.”)

Note: The attachment tilt cylinder is heavy. Use a hoist

and sling to support the attachment tilt cylinder when the

base end pin is removed.

21. Remove the retaining ring (Fig. 3-12, 1) from one

side of the base end pivot pin (2). Save the retaining

ring. Use a brass punch and rawhide hammer to

remove the base end pivot pin from the inner boom

gooseneck (3).

22. Inspect the pin for nicks or surface corrosion. Use

fine emery cloth to fix minor nicks or corrosion. If

damaged and not repairable, the pin must be

replaced.

23. Lower the attachment tilt cylinder (Fig. 3-12, 4) with

the hoist, and remove it from the rear of the

gooseneck. Place the attachment tilt cylinder on a

clean, level surface until installation.

Figure 3-12 Remove Attachment Tilt Cylinder

Note: Use a hoist capable of lifting 5000 lbs (2268 kg)

and two slings to remove the inner boom.

24. Place the slings around the inner boom. Pull the

inner boom straight out of the intermediate boom.

25. Reposition the sling at the approximate center of the

inner boom, and then continue withdrawing the boom

until it clears the vehicle.

26. Carefully lower the inner boom onto suitable

supports to prevent it from tipping over.

27. Inspect the boom and welds. Contact the JLG

Service Department or the local JLG Authorized

Service Center (ASC) if structural damage is

detected.

28. Inspect hoses, hardware, wear pads, mounting

points, chains and other components visible with the

inner boom removed. Replace if damaged.

29. At the rear of the inner boom (Fig. 3-13, 1), remove

the capscrews (2), lockwashers (3) and flat washers

(4) holding the top wear pads (5), spacers (6) and

shims (7) to the top of the inner boom. Label the

wear pads, spacers and shims as “Top Left” and

“Top Right” sides. Save the spacers, shims,

capscrews, lockwashers and wear pad inserts (8).

MA7810

1

3

2

4

WARNING:

NEVER weld or drill the

boom. The structural integrity of the boom will

be impaired if subjected to any repair involving

welding or drilling. Failure to comply can result

in death or serious personal injury.

MA6450

1

2

3

4