Sandvik Coromant Heat resistant super alloys User Manual

Page 98

96

80

60

40

20

0

80

60

40

20

0

min

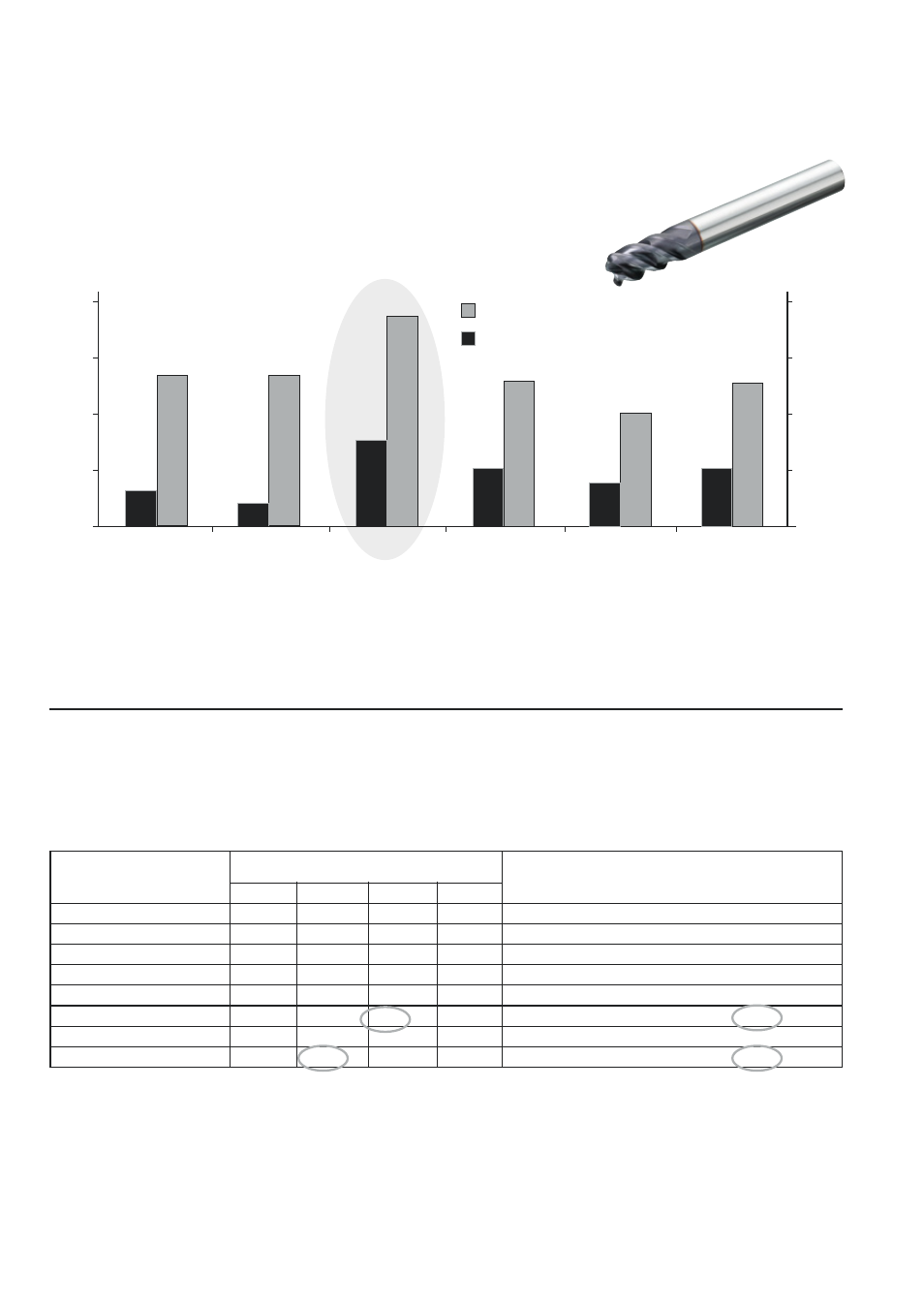

R215.36-12050- R215.3C-12030- R216.24-12050- R216.24-12050- R216.34-12050- R216.34-12050-

AC26L 1620

AC26H 1610

GAK26P 1620

GAK26P 1630

AK26P 1630

AK26P 1620

= Total metal removed

= Tool life

cm

3

First choice recommendations for HSM

It can be seen in the diagram that R216.24-12050-GAK26P 1620 is the optimised cutter

for HSM in Inconel.

Total metal removed and tool life vs radial cut

Material: Inconel 718

v

c

100 m/min, a

e

0.5 mm, a

p

10 mm,

f

z

0.05 mm/tooth, h

ex

0.02 mm

8

10

12

16

20.0%

1.6

2

2.4

3.2

53°

1.3

0.05

17.5%

1.4

1.75

2.1

2.8

49°

1.3

0.05

15.0%

1.2

1.5

1.8

2.4

46°

1.4

0.06

12.5%

1

1.25

1.5

2

41°

1.5

0.06

10.0%

0.8

1

1.2

1.6

37°

1.7

0.07

7.5%

0.6

0.75

0.9

1.2

32°

1.9

0.08

5.0%

0.4

0.5

0.6

0.8

26°

2.3

0.09

2.5%

0.2

0.25

0.3

0.4

18°

3.2

0.13

Depth of cut to

diameter ratio a

e

/D

c

Depth of cut for cutter diameter, mm

Entering

angle

k

r

Feed

modification

Feed f

z

for

0.04 h

ex

Recommended start cutting data for milling HRSA materials with CoroMill Plura

Finishing

75

1.5 x D

c

0.25 to 0.5

0.04

0.1

22

75

1.5 x D

c

8% D

c

0.04

0.08

16

Roughing

v

c

, m/min a

p

, mm

a

e

, mm

h

ex

mm f

z

mm/tooth

Tool life, min

Select feed depending upon percentage radial depth of cut

e.g. roughing:

D

c

12 mm, a

e

0.9 mm, f

z

0.08 mm

e.g. finishing:

D

c

10 mm, a

e

0.25 mm, f

z

0.13 mm