Milling, Terminology and units formulas – Sandvik Coromant Heat resistant super alloys User Manual

Page 121

119

Milling

D

cap

= Cutting diameter at actual depth of cut, a

p

mm

l

m

= Machined length

mm

a

p

= Cutting depth

mm

a

e

= Working engagement

mm

v

c

= Cutting speed

m/min

Q

= Metal removal rate

cm

3

/min

T

c

= Machining time

min

z

n

= Total number of teeth in cutter

piece

f

z

= Feed per tooth

mm/r

f

n

= Feed per revolution

mm

v

f

= Table feed (feed speed)

mm/min

h

ex

= Max chip thickness

mm

h

m

= Average chip thickness

mm

z

c

= Effective number of teeth

piece

k

c1

= Specific cutting force (for h

ex

= 1 mm)

N/mm2

n = Spindle speed

r/min

P

c

= Cutting power net

kW

κ

r

= Entering angle

degrees

m

c

= Rise in specific cutting force (k

c

)

as a function of chip thickness

iC = Inscribed circle

γ

0 = Chip rake angle

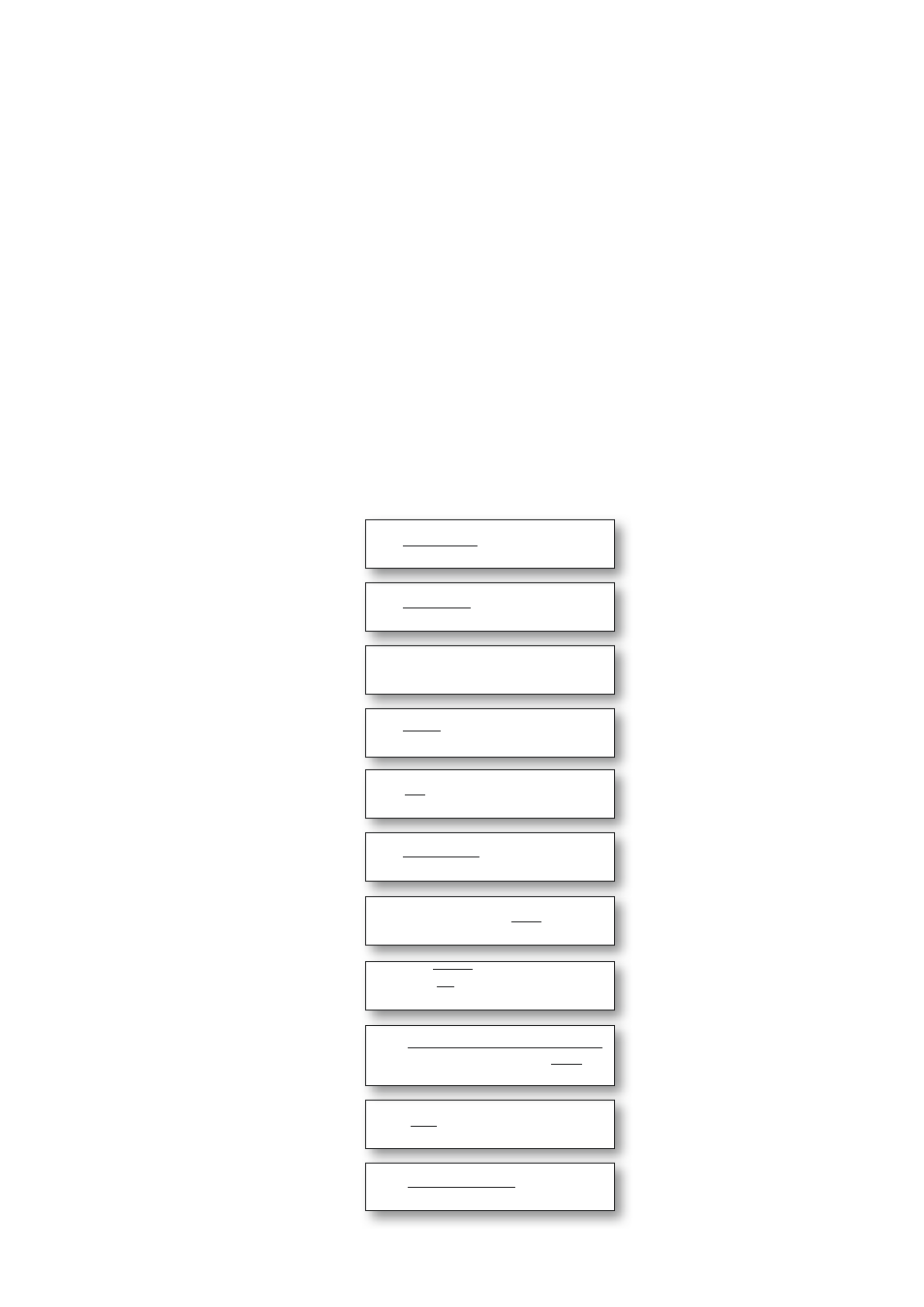

Feed per revolution

(mm/r)

Feed per tooth

(mm)

Table feed (feed speed)

(mm/min)

Spindle speed

(r/min)

Cutting speed

(m/min)

Terminology and units

Formulas

Machining time

(min)

Average chip thickness (mm)

when a

e

/D

c

≥ 0.1

Net power

(kW)

Metal removal rate

(cm

3

)

Specific cutting force

(N/mm

2

)

Average chip thickness (mm)

(Side and facemilling) when a

e

/D

c

≤ 0.1

v

f

= f

z

× n × z

n

f

z

=

v

f

n

× z

c

n =

v

c

× 1000

π × D

cap

v

c

=

D

cap

× π × n

1000

f

n

=

v

f

n

T

c

=

l

m

v

f

Q =

a

p

× a

e

× v

f

1000

k

c

= k

c1

× h

m

-mc

×

P

c

=

a

p

× a

e

× v

f

× k

c

60 × 10

6

h

m

=

sin

κ

r

Ч 180 Ч a

e

× f

z

π × Dcap × arcsin

(

a

e

)

D

cap

h

m

≈ f

z

a

e

D

cap

√

1 -

γ

0

(

100

)