Effect of geometry/ f – Sandvik Coromant Heat resistant super alloys User Manual

Page 75

73

40

30

20

10

0

E-MM

M-PM

E-PL

Tool R300-063Q22-12H, z

n

7, D

c

51 mm, v

c

30 m/min,

a

e

36 mm, a

p

2 mm,

Material: Inconel 718 (44 HRC)

Minutes in cut

S40T

S40T

S40T

R300-1240E-PL

R300-1240E-PL

R300-1240E-PL

h

ex

0.12 mm

h

ex

0.18 mm

h

ex

0.24 mm

f

z

0.16 mm/tooth

f

z

0.24 mm/tooth

f

z

0.32 mm/tooth

= Average time in cut

= Average volume removed

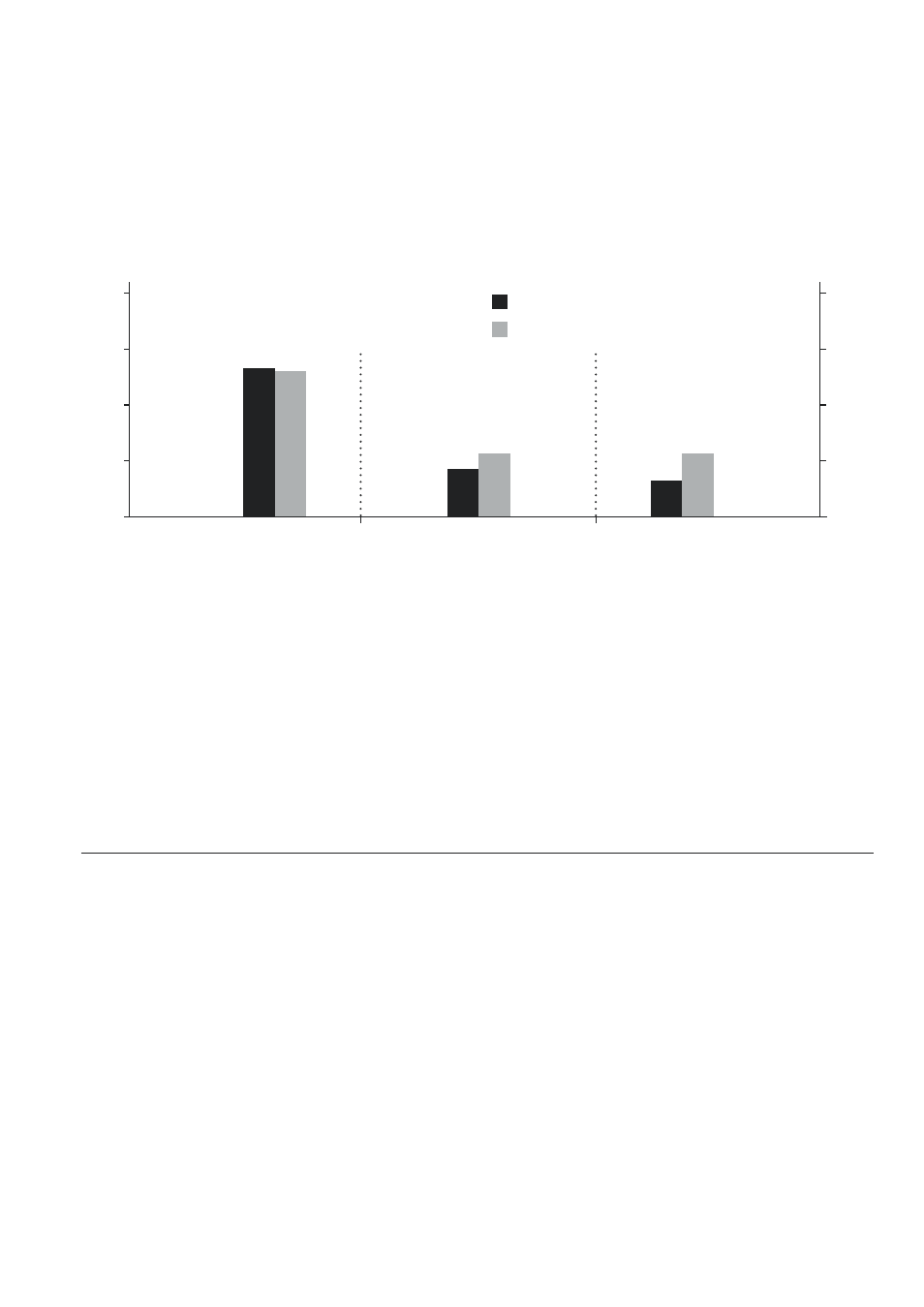

The graph below shows the effect of the geometry depending upon the feed/tooth.

Total metal removed, cm

3

Recommendation – maximum productivity

and metal removal rates were achieved

using E-PL geometry at 0.16 mm

feed/tooth (0.12 mm h

ex

).

Geometry

0.1 mm

0.15 mm

Min (f

z

)

Max (f

z

)

0.22 mm

0.3 mm

Effect of geometry/f

z

0.08 mm

0.18 mm

610

420

280

140

0