Cutting speed ( v – Sandvik Coromant Heat resistant super alloys User Manual

Page 95

93

20

52

40

35

30

25

20

15

10

5

0

80

70

60

50

40

30

20

10

0

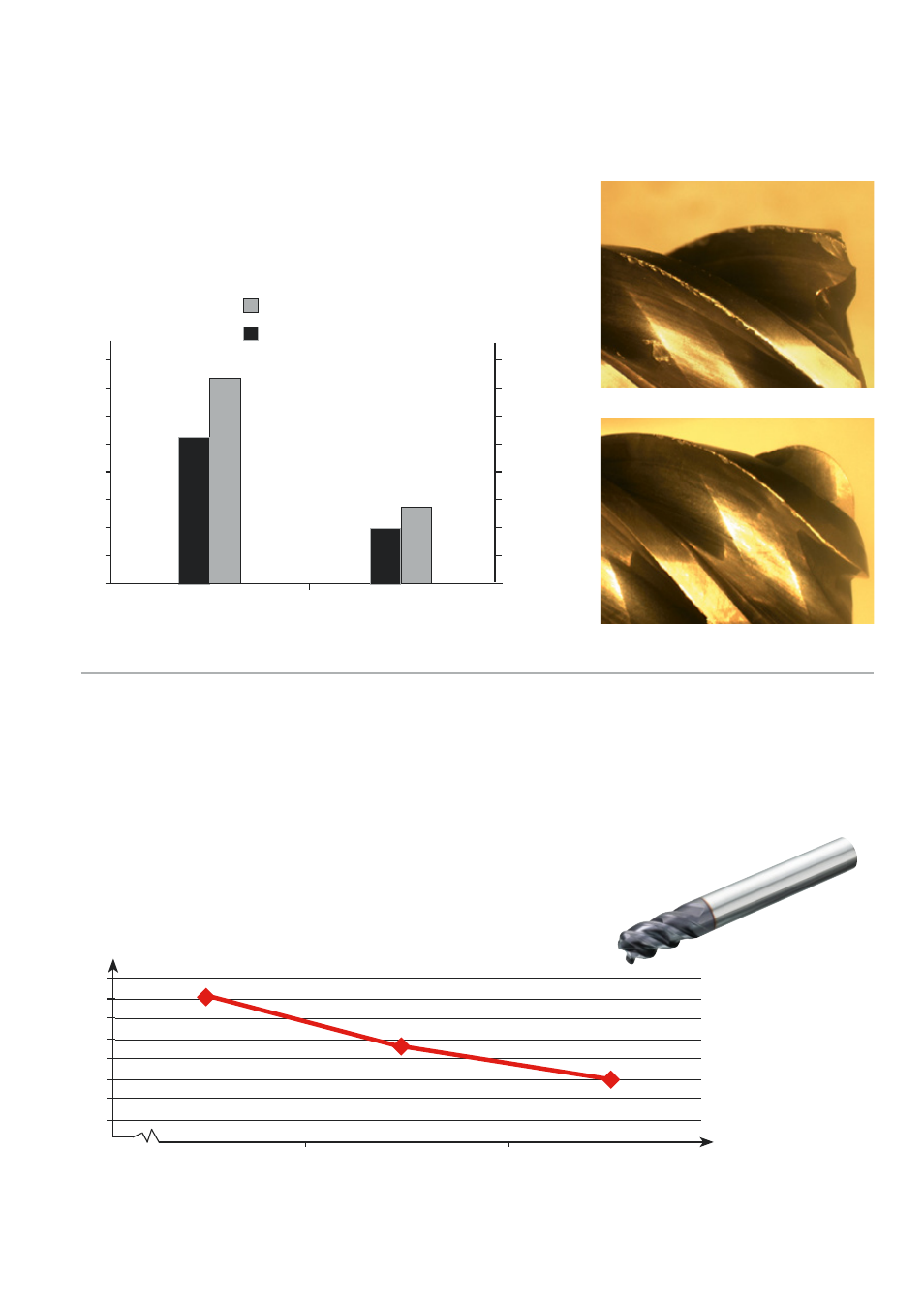

Corner geometry

The main wear observed in the case of HSM in Inconel is micro chipping at the cutting

edge. A radius end mill, due to increased strength is always better compared to a chamfer

or sharp corner.

Comparison between chamfer and radius end mill

v

c

100 m/min, a

p

10 mm, h

ex

0.02 mm,

a

e

0.5 mm, f

z

0.05 mm/tooth

Material: Inconel 718

Minutes

R216.24-12050-GAK26P

R216.34-12050-AK26P

1620/R3

1620/Chamfer

= Total metal removed

= Tool life

cm

3

Cutting speed (v

c

)

Because of the relatively low radial engagements in HSM one can make use of higher than

normal cutting speed (v

c

), 75 to 100 m/min gives the best balance between productivity

and tool life. The chart shows the difference in performance relative to cutting speed.

75

100

125

Cutting speed,

m/min

Tool life, min

Tool life vs cutting speed

R216.24-12050-GAK26P 1620, a

p

10 mm,

a

e

0.5 mm, h

ex

0.02 mm, f

z

0.05 mm/tooth

Material: Inconel 718

80

70

60

50

40

30

20

10

0

73

27