Sandvik Coromant Heat resistant super alloys User Manual

Page 22

20

+

–

+

–

+

Application hints

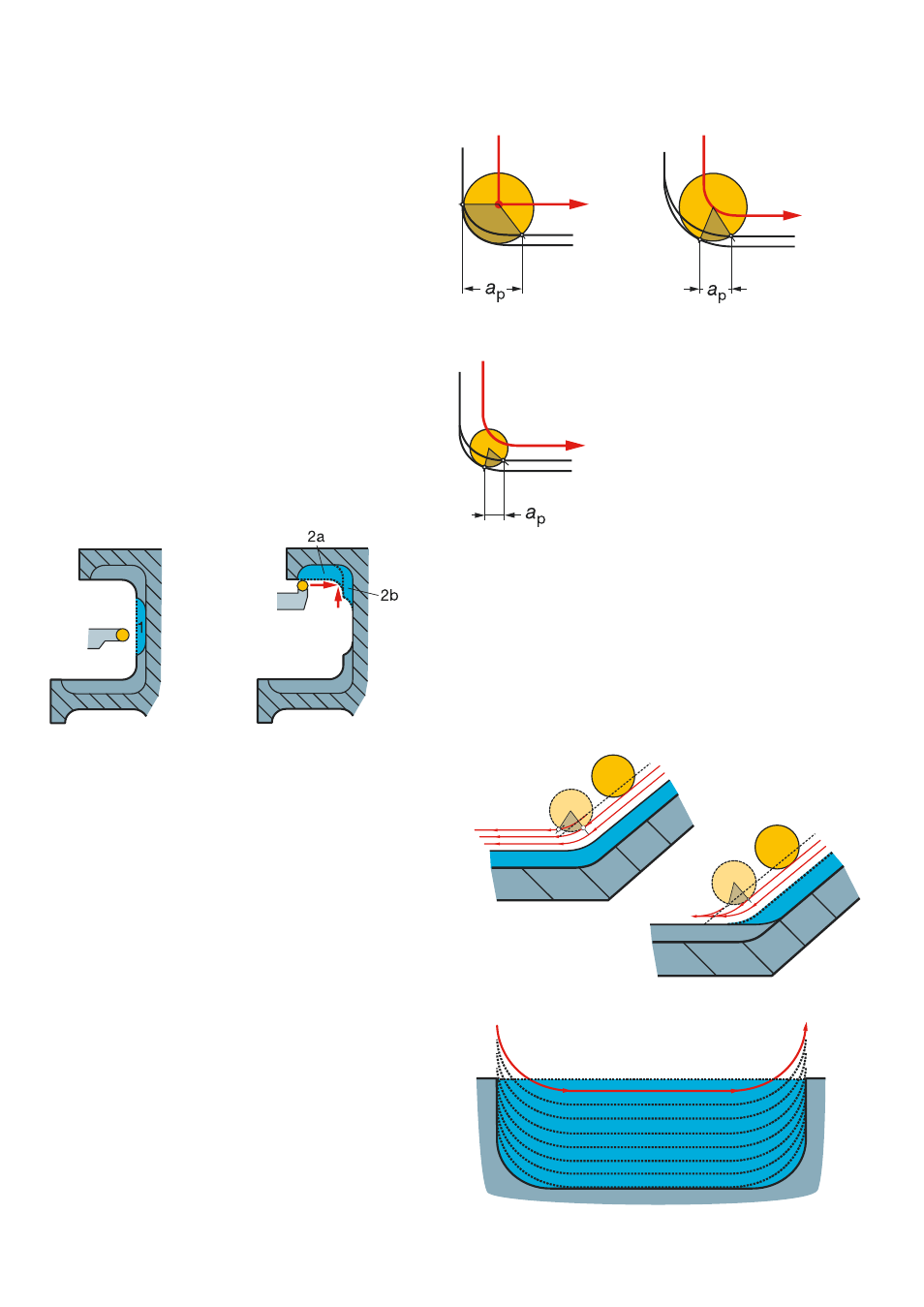

‘Wrap-around’ is a problem which occurs

with round inserts when plunging or pro-

filing into corners. Due to high angular

engagement creating high cutting pres-

sures, the feed needs to be reduced. To

reduce this problem, optimized program-

ming strategies together with smaller insert

radii should be used.

Recommendations

1) Never plunge straight into cut.

2) Roll in and out of cut.

3) Roughing – programmed radius same

size as insert diameter.

4) Finishing – insert diameter no greater

than 1.75 times programmed radius.

Insert too large

for radius

Radius increased

for insert

Insert decreased

for radius

The component feature to be machined

needs to be broken down into stages so

that a face and diameter are not machined

simultaneously as this will naturally

increase the depth of cut and cause ‘wrap-

around’

Because of the wrap around problem in the

radii, the feed needs to be reduced as the

size of cut increases. The larger the dif-

ference between the radius and the insert

diameter, the less the feed needs to be

reduced.

However a good starting point is to use

50% feed rolling into radius compared to

parallel cuts.

Programming recommendations

By breaking the part into manageable

pieces this method can be used for all pro-

filing requirements. The direction of passes

can be alternated when using CoroCut and

RCGX inserts to best utilise the edge.

‘Trochoidal turning’

f

n max

50% f

n max

Face and

diameter

Only

diameter

Programmed radius = insert diameter

50% f

n mбx