Grade choice and effect of milling direction, Should be selected to provide a chip thickness, h – Sandvik Coromant Heat resistant super alloys User Manual

Page 88

86

v

c

h

ex

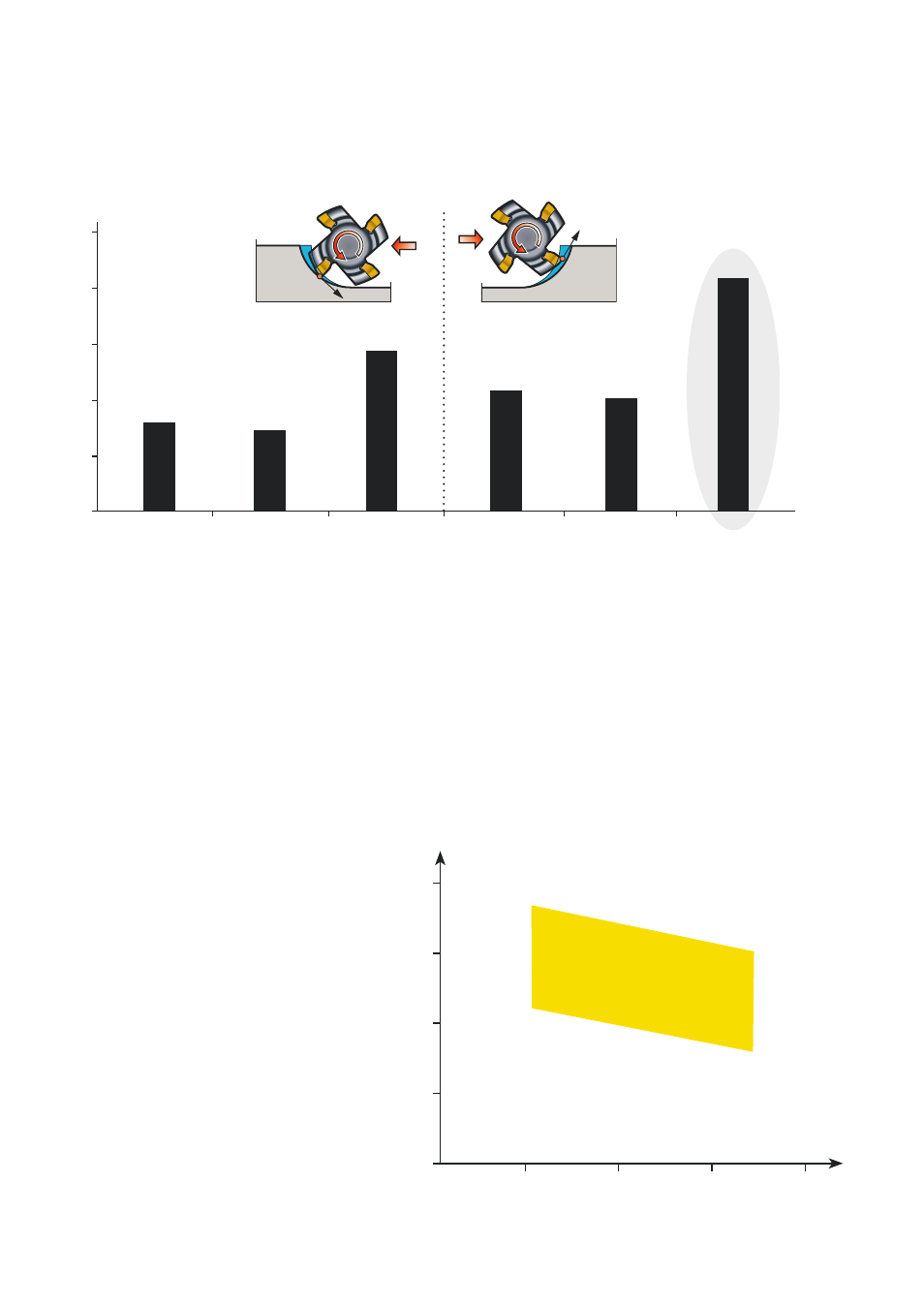

Grade choice and effect of milling direction

D

3

63 mm, z

n

4, v

c

1000 m/min, a

e

32 mm,

f

z

0.11 mm/tooth, h

ex

0.07 mm, a

p

1.5 mm (no coolant)

Material: Inconel 718 (40 HRC)

5

4

3

2

1

0

RNGN 670

RNGN 6080

RNGN 6060

RNGN 670

RNGN 6080

RNGN 6060

Down/climb milling

Up/conventional milling

Minutes in cut

The diagram shows that:

• New Sialon grade CC6060 gives the outstanding performance.

• Up/conventional milling provides a longer tool life and more consistent wear compared

to down/climb milling. This is due to the reduced impact force on entering the material

better suited to ceramic material.

Short tool

life – cutting

temperature

too high

Edge line frittering

– cutting

temperature

too low

W

or

k

hardening

of

wor

kpiece

material

Top

slice

–

high

cutting

pressure

Cutting data recommendation

The speed should be balanced to

create enough heat in the cutting

zone to plasticize the chip, but

not so high as to unbalance the

ceramic.

The feed, f

z

, should be selected to

provide a chip thickness, h

ex

, which

is high enough so as not to work-

harden the material, but not so high

as to cause edge frittering.

Higher feeds and depths of cut

require a reduction in the cutting

speed, v

c

.

Application

area

CC6060

1200

900

600

300

0

0.025

0.05

0.075

0.1