Thread milling – Sandvik Coromant Heat resistant super alloys User Manual

Page 112

110

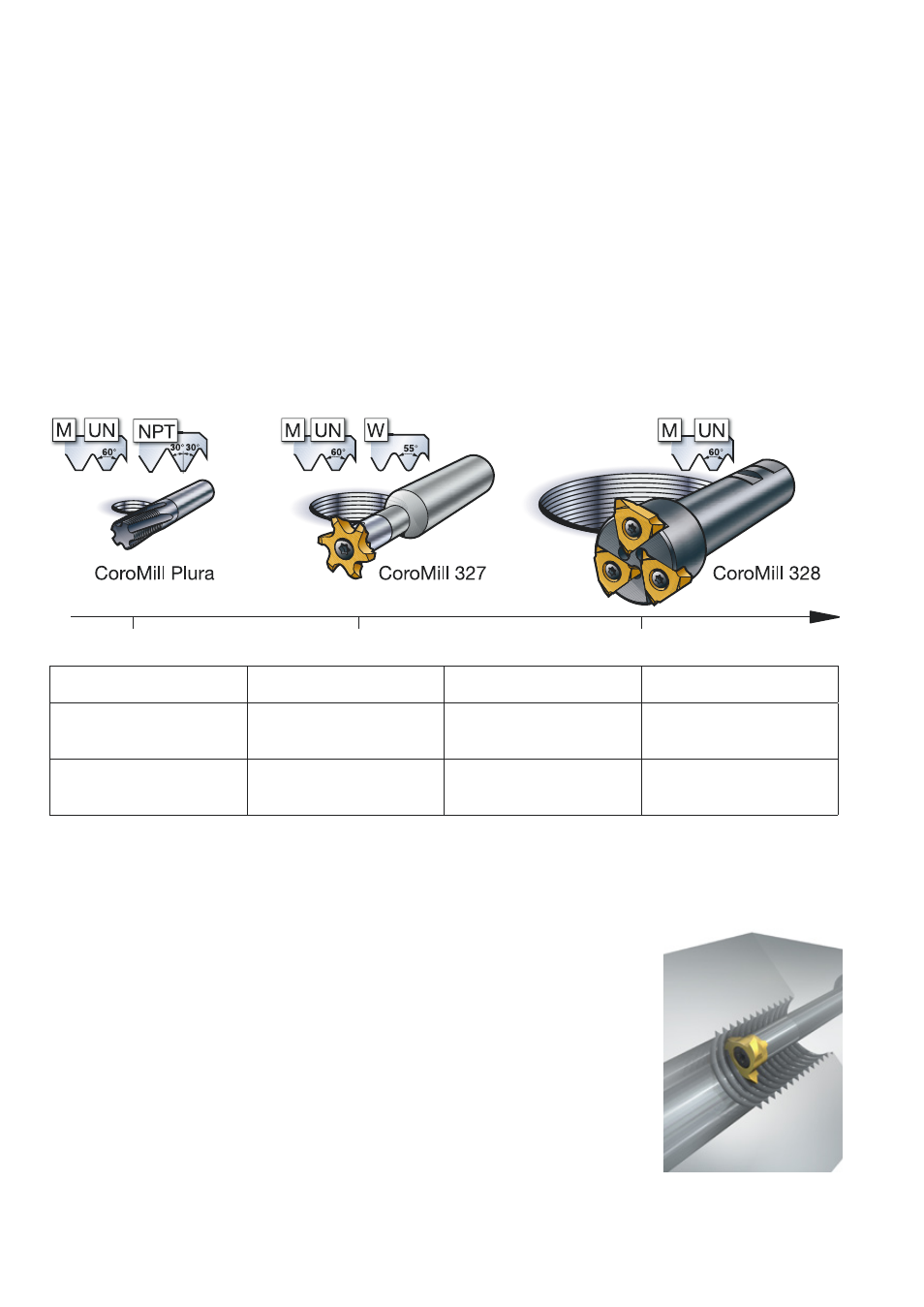

CoroMill® Plura

CoroMill® 327

CoroMill® 328

Pitch

0.7 – 3 mm

28 – 10 t.p.i.

1 – 4.5 mm

24 – 5 t.p.i.

1.5 – 6 mm

16 – 4 t.p.i.

Cutter dia (Dc), mm

3.2 – 19

11.7 – 21.7

39 – 80

Thread milling

Many holes in a typical aerospace engine casing require threads.

Machining the thread in smaller holes can prove to be a difficult

operation. This can be performed using a tap to machine the

thread. However in HRSA materials this can cause problems with

chip jamming resulting in tap breakage and ultimately scrapping of

an expensive component.

The main options for thread milling using Sandvik Coromant tools

are single-point threading with CoroMill 327 and CoroMill 328, and

multi-point threading with CoroMill® Plura.

All tools produce different threads of the same pitch with one tool.

Single-point threading

CoroMill®327

Designed for holes over 12 mm, CoroMill 327 offers inserts for

metric, UN and Whitworth threads.

The front-mounted inserts are positioned in grooves for secure

mounting, and through-tool coolant aids chip evacuation, giving

secure and continuous performance. CoroMill 327 is available in

versatile grade GC1025, for all material types.

CoroMill 327 has Weldon shanks, steel or solid carbide.

∅ 3,2

∅ 39

∅ 11.7