Face milling with carbide inserts, Effect of insert style – Sandvik Coromant Heat resistant super alloys User Manual

Page 70

68

45

40

35

30

25

20

15

10

5

0

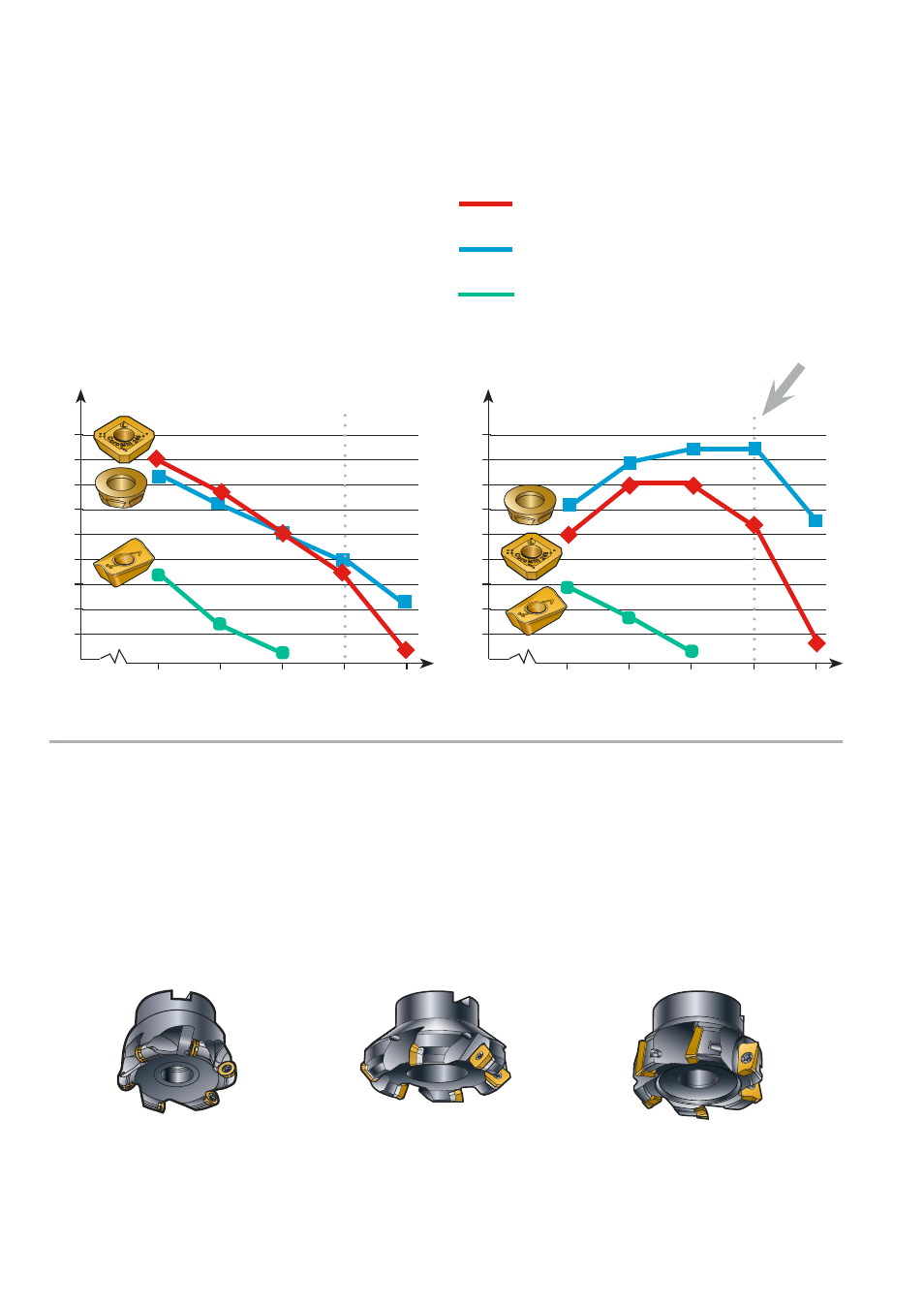

Effect of insert style

Chip thickness, cutting forces and tool life

are affected by the choice of insert style

when milling HRSA materials.

Recommendation – for general face milling in HRSA materials – use round insert cutters

whenever possible to increase chip thinning effect – CoroMill 300.

1st choice

2nd choice

3rd choice

Round inserts

45º

90º

CoroMill®300

CoroMill®245

CoroMill®390

Face milling with carbide inserts

450

400

350

300

250

200

150

100

50

0

0.1

0.15

0.2

0.25

0.3

R245-050Q22-12H, z

n

5,

R245-12T3E-ML GC2040

R300-063Q22-12H, z

n

7,

R300-1240E-MM GC2040

R390-050Q22-11H, z

n

7,

R390-11T308E-ML GC2040

D

c

50 mm, v

c

30 m/min, a

e

32 mm (70%), a

p

2 mm

Material: Inconel 718 (42 HRC)

Feed mm/tooth

Minutes in cut

0.1

0.15

0.2

0.25

0.3

Feed mm/tooth

Metal removal, cm

3

CoroMill 300

optimal productivity