Sandvik Coromant Heat resistant super alloys User Manual

Page 77

75

100

80

60

40

20

0

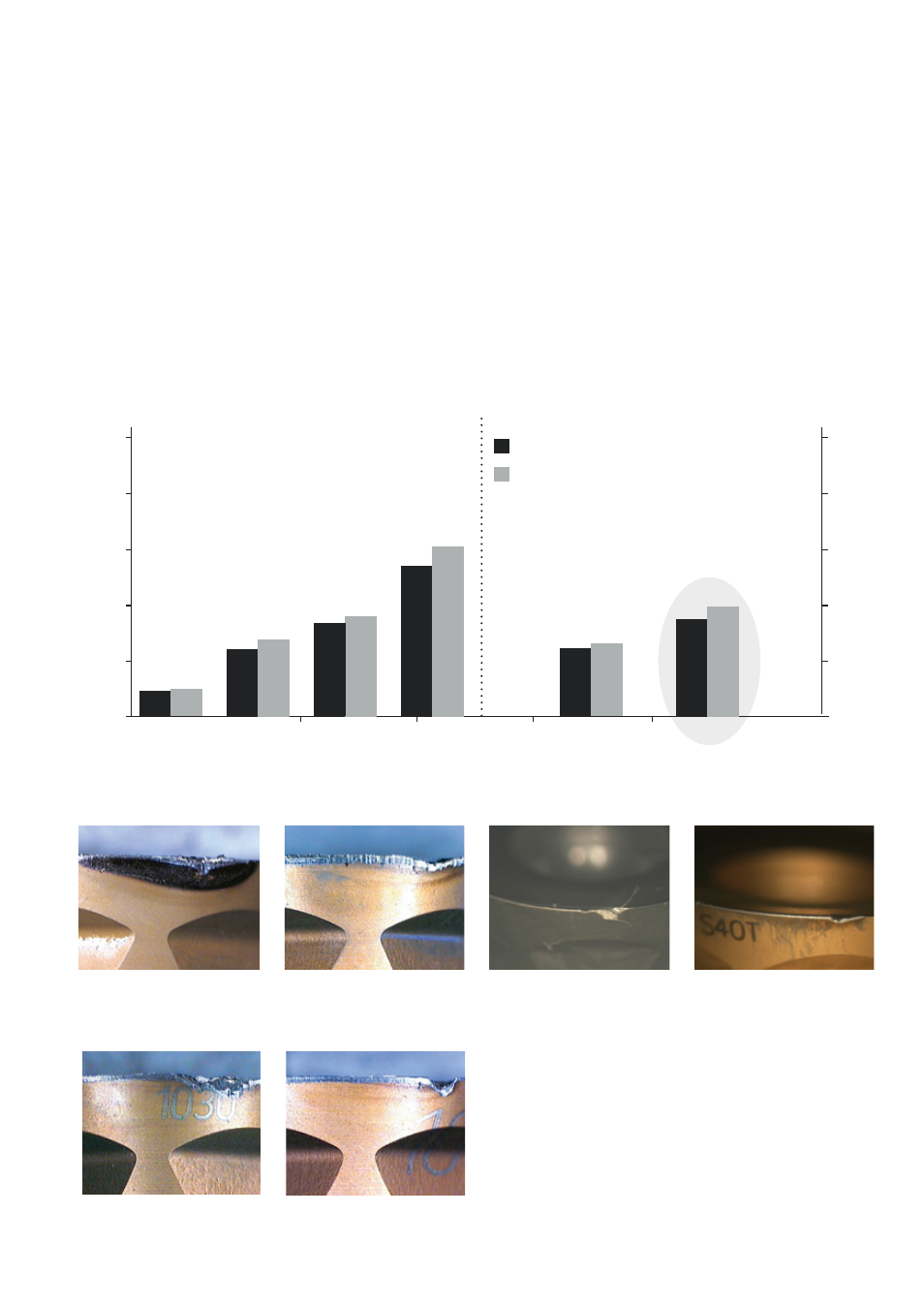

Effect of hardness with grade and geometry, E-PL 1030

It can be seen that in harder materials new grade and geometry

E-PL 1030 withstands the heat created during cutting much better

than E-PL S40T.

The harder substrate combined with optimised micro geometry has

better resistance to notch wear and plastic deformation.

Tool R300-063Q22-12H,

D

c

51 mm, f

z

0.24 mm/tooth, h

ex

0.18 mm,

a

p

2 mm, a

e

36 mm, v

c

30 m/min

Material: Inconel 718

Minutes in cut

S30T E-PL

S40T E-PL

GC1030 E-PM GC1030 E-PL

GC2040 E-MM

GC1030 E-PM

Softer batch (44 HRC)

Harder batch (46 HRC)

= Average time in cut

= Average volume removed

Total metal removed, cm

3

Hardness 40 HRC

E-MM 2040 – 25 min

E-PM 1030 – 55 min

E-PL S30T – 10 min

E-PL S40T – 33 min

Hardness 46 HRC

E-PM 1030 – 24 min

E-PL 1030 – 36 min

Hardness 44 HRC

1750

1400

1050

700

350

0