Carbide insert grades, Gc1105 – Sandvik Coromant Heat resistant super alloys User Manual

Page 28

26

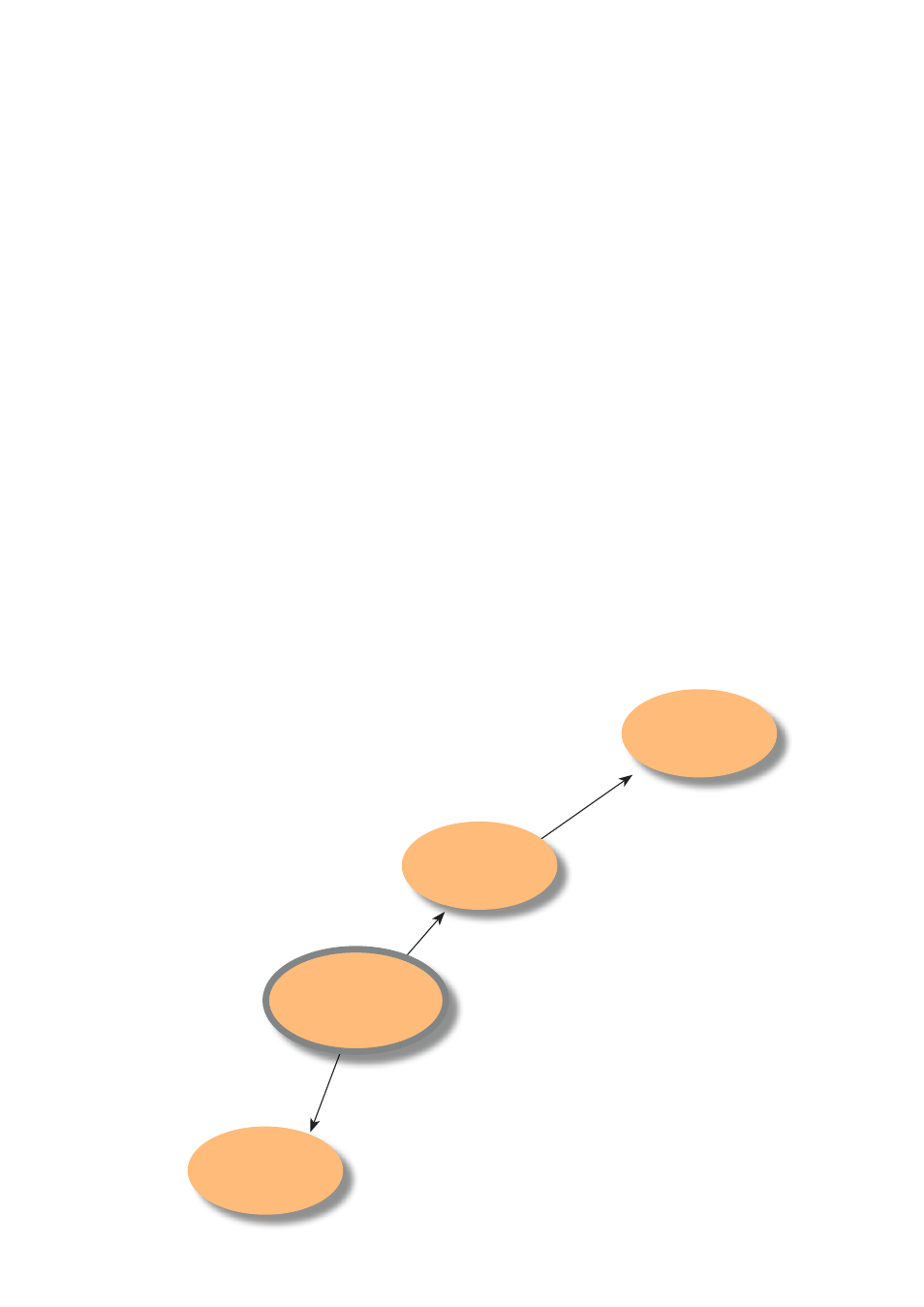

GC1105

H13A

GC1115

S05F

Carbide insert grades

GC1105

A TiAlN PVD coated fine-grain carbide with

good hot hardness and toughness pro-

perties. It is optimized for inserts with 95º

entering angle but is an all-round grade giv-

ing effective performance through FSM, ISM

and LSM areas.

The coating gives extremely good adhe-

sion which is required for lower feeds and

depths of cut. SGF is a ground insert with

sharp edges, this combined with GC1105

is outstanding in extreme finishing on vibra-

tion sensitive components with low feeds.

GC1115

A micro-grained carbide providing security

in more edge toughness demanding opera-

tions, e.g. reduce problems with notch wear

or chip hammering.

The PVD coating contains TiAlN for edge

line toughness as well as an aluminium

chromium oxide providing resistance

against built-up formation and crater wear.

A good balance of toughness and wear

resistance makes GC1115 ideal also for

more unstable conditions.

S05F

A CVD coated fine grain carbide with excel-

lent hot hardness properties. It is opti-

mized for applications with a 45º approach

(square, round, CoroCut RO and finishing).

The CVD coating provides an excellent heat

barrier allowing greater productivity and tool

life through ISM and LSM.

It is a grade for optimizing productivity

which does not allow for applications with

entering angles over 75º due to poor notch

wear resistance.

When in need of a more secure

solution, in more edge toughness

demanding operations.

When in need of more heat

and wear resistance at enter-

ing angles less than 75°.

When in need of more bulk

toughness or if an uncoated

grade is required.

First choice