Circular ramping from solid, Cutter and hole diameter, Programmed feed rates – Sandvik Coromant Heat resistant super alloys User Manual

Page 109: Feed rate, Pitch, When using radius compensation • v, When using the tool centre feed, The axial pitch ( a

107

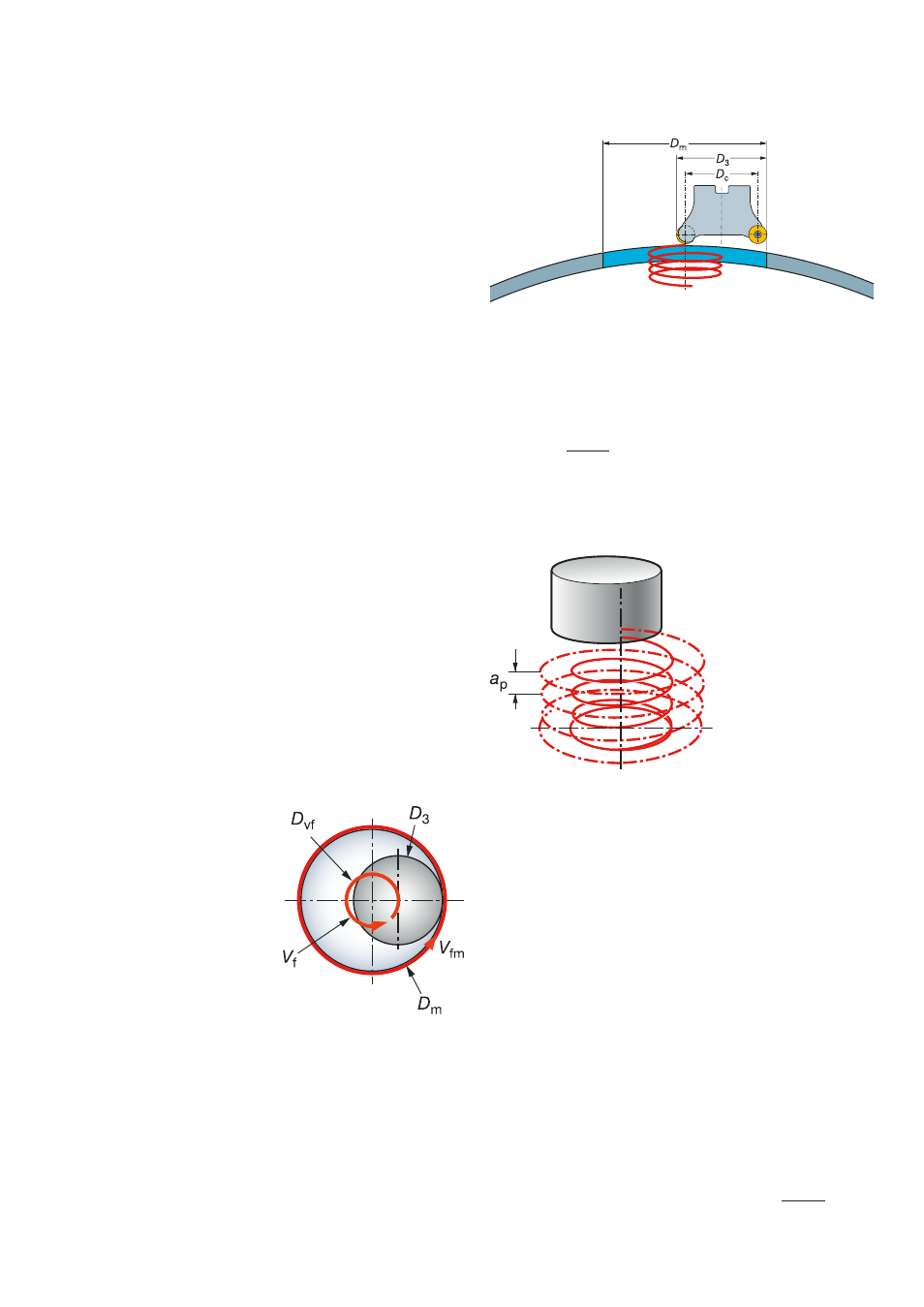

Cutter and hole diameter

The ramping process requires a cutter

which is capable of axial cutting. The dia-

meter selection is very important when

using cutters which are not centre cutting.

The diameter of the cutter, minus the insert

radius, should not exceed half the hole dia-

meter. This is to ensure that there is no

‘pip’ remaining.

D

vf

= D

m

– D

3

Programmed feed rates

•

v

fm

– when using radius compensation

•

v

f

– when using the tool centre feed

Circular ramping from solid

Example

D

m

= 58

D

3

= 35

v

c

= 25

f

z

= 0.2

D

vf

= 18

a

p

= 2

z

n

= 4

n

= 227

v

fm

= 182

v

f

= 76

Tool centre feed diameter – D

vf

Min D

m

= (D

3

– 0.5iC) x 2

D

m

2

Max D

3

= + 0.5iC

Feed rate

The feed rate must be reduced in internal

applications due to the periphery of the tool

moving faster than the centre line of the

tool.

Programming of the feed rate (mm/min)

on most milling machines/CAM systems

is based on the centre line of the spindle

requiring a manual recalculation.

Pitch

The axial pitch (a

p

) per revolution is deter-

mined by the max depth of cut limitation

for the cutter concept (0.15 x iC for round

inserts).

v

fm

= n x f

z

x z

n

Milling of holes is a flexible process able to

produce a range of hole sizes with each cut-

ter. It produces low axial cutting forces and

copes well with interrupted entrances and

exits which are a problem when machining

into curved surfaces such as casings.

D

vf

D

m

v

f

=

x v

fm