Turning of cobalt-based materials, Turning of cobalt-based materials – medical, Material properties – Sandvik Coromant Heat resistant super alloys User Manual

Page 53

51

3. Turning of cobalt-based materials

– medical

+ resistant to wear

(hard material 45-50 HRC).

+ can be cast into complex shapes.

+ high corrision resistance.

+ stronger than stainless steel.

– twice the weight of stainless steel.

– very brittle under impact loading.

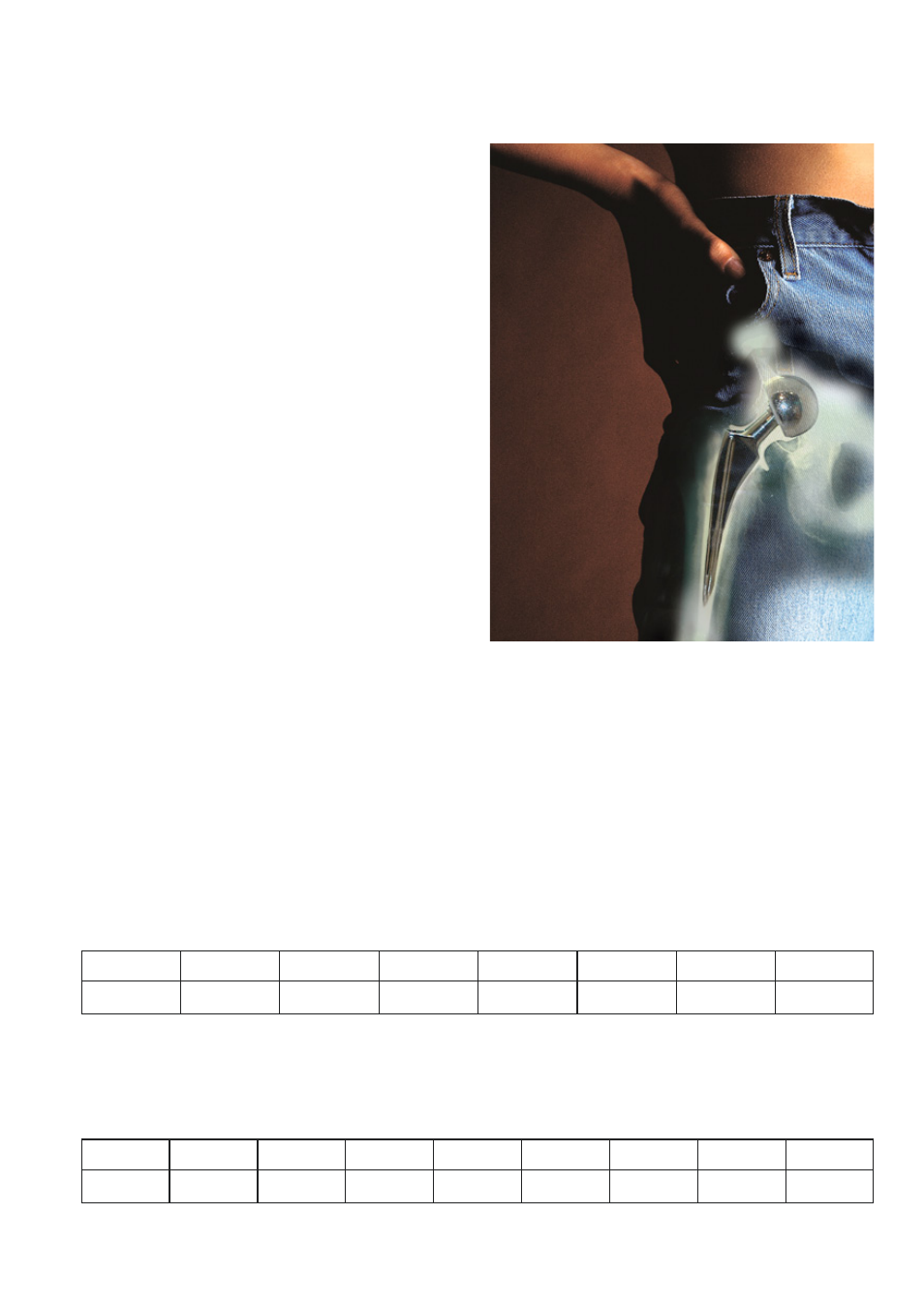

The cobalt-based alloys in the medical

area are mainly of two types: CoCrMo and

CoNiCrMo.

CoCrMo alloys are used in applications

such as fixation screws, bone plates, shoul-

der, knee and hip replacement (coated or

uncoated, cemented or uncemented).

In this chapter of the application guide we

focus on the machining of hip joints in the

material group CoCrMo.

Chemical compositions of a few

Co-based alloys for implants

CoCr28Mo6 ASTM F75

Vitallium (Howmedica, Inc)

Haynes-Stellite 21 (Cabot Corp.)

Protasul-2 (Sulzer AG)

Micrograin-Zimaloy (Zimmer)

Co

Cr

Mo

Mn

Si

Ni

Fe

C

58.9–69.5

27.0–30.0

5.0–7.0

Max 1.0

Max 1.0

Max 1.0

Max 0.75

Max 0.35

CoCrMo ASTM F799

Forged CoCrMo

Thermomechanical CoCrMo

FHS (Forged high strength)

Co

Cr

Mo

Mn

Si

Ni

Fe

C

N

58–59

26.0–30.0 5.0–7.0

Max 1.0

Max 1.0

Max 1.0

Max 1.5

Max 0.35

Max 0.25

Material properties