Geometries and chip breaking, Recommendation for tool geometry, 31 -sgf – Sandvik Coromant Heat resistant super alloys User Manual

Page 33: Smr -sf -sm, First choice

31

-SGF

CoroCut®

Q-Cut

SF

SGF

MF

*CGT-UM

SM

MM

MR

SM

QM

QM

GF

RO

RO

TF

TF

4G

4P

4P

5E

SM

1)

1)

SMR

SMR

SM

Xcel

a

p

f

n

-SMR

-SF

-SM

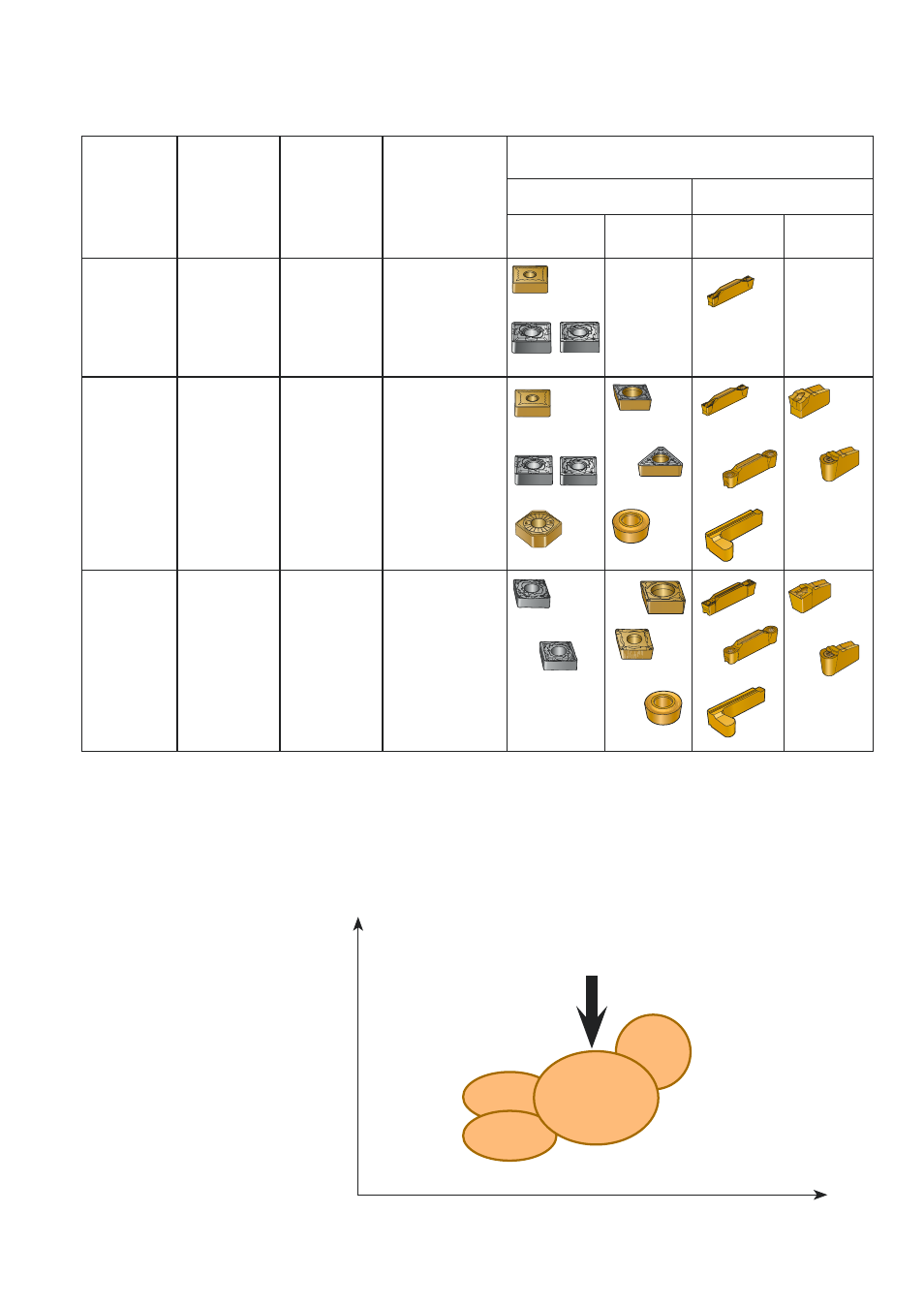

Geometries and chip breaking

Recommendation for tool geometry:

Application

area

Feed range,

mm

Edge

rounding

Geometry

requirements

Geometry recommendation

General turning

Grooving

Double

sided

Positive

Direct pressed

ground

Direct pressed

positive rake

angle

Direct pressed

– primary land

Medium

1) CoroCut angled inserts, see page 37.

Note: the ground inserts -SGF and *CGT-UM should be used for thin walled components to minimize the cutting

forces and hence risk of distortion.

ISM

0.15 to 0.25

LSM

0.1 to 0.2

Small

FSM

0.20 to 0.4

First choice

High feed rates,

interuptions

Lowest tool

pressure

Chip

breaking

ISO S geometries

First choice recom-

mendations for general

turning with double

sided inserts.

Medium to

small