Cutter concept – Sandvik Coromant Heat resistant super alloys User Manual

Page 66

64

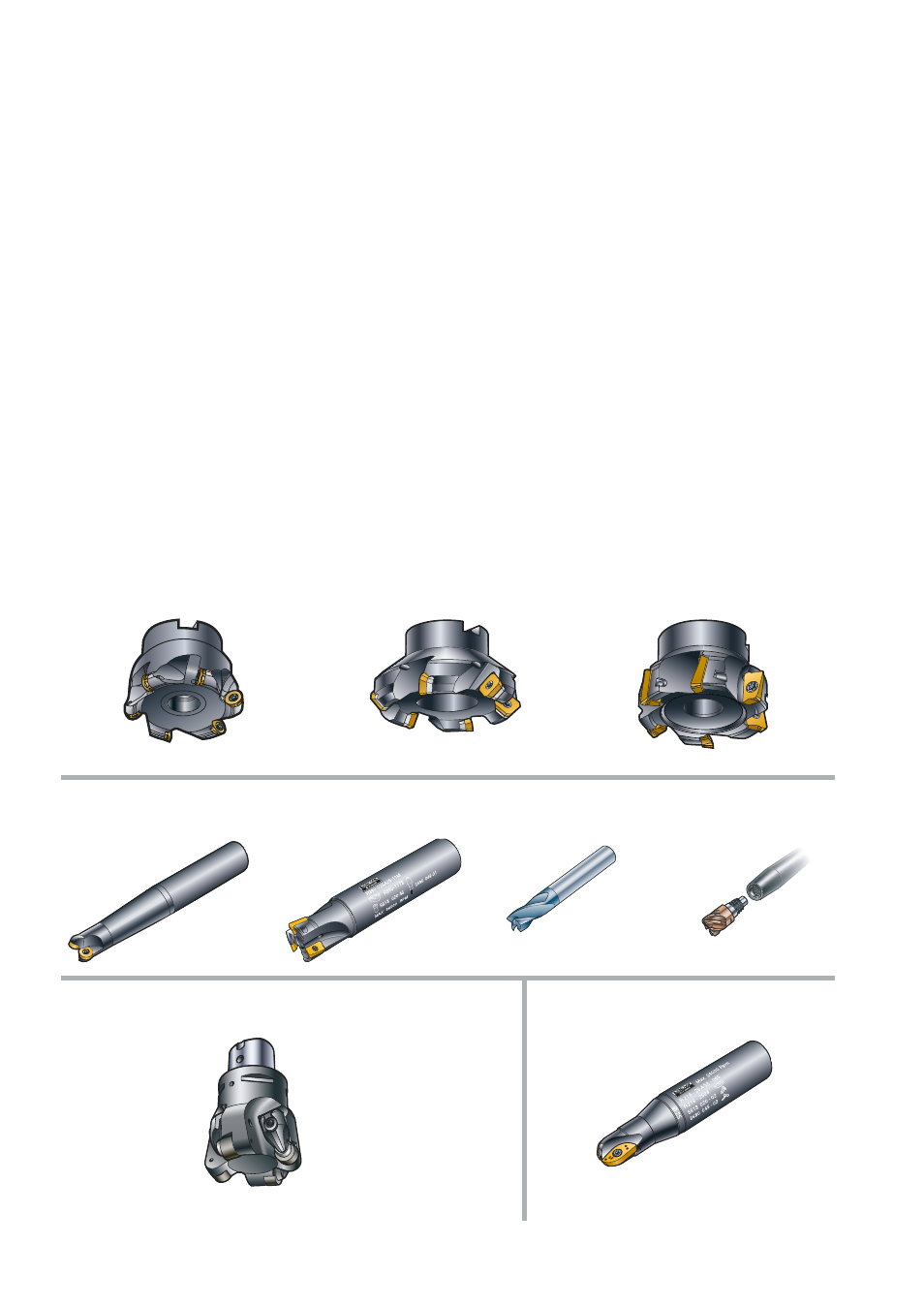

CoroMill® 300

CoroMill® 245

CoroMill® 390

CoroMill® 300

CoroMill® 390

CoroMill® Plura

CoroMill® 316

S-R120R/CoroMill® 300C

Cutter concept

Modern milling is a very universal machin-

ing method. During the past few years hand

in hand with machine tool developments,

milling has evolved into a method that

machines a very broad range of configura-

tions. The choice of cutter concept is no

longer straightforward – in addition to all

the conventional applications, milling is

a strong contender for producing holes,

threads, cavities and surfaces that used to

be turned, drilled, or tapped etc. (See hole

making chapter). Tooling developments have

also contributed to the new possibilities

along with the gains in productivity, reliabil-

ity and quality consistency that have been

made in indexable and ceramic inserts.

The aim is to have a strategy suited to the

machine tool and feature to be machined

giving a maximum metal removal rate (Q

cm

3

/min) that can be balanced with an

economic tool life.

For milling there are many variables to

consider:

D

c

– cutter diameter

z

n

– number of effective teeth

k

r

– entering angle

a

p max

– maximum cutting depth

a

e max

– maximum radial cut

End mills

Round inserts

90º

Solid carbide

Exchangeable head

Design types

Face mills

Round inserts

45º

90º

Ceramic insert cutter

Ball nose

CoroMill® Ball nose 216