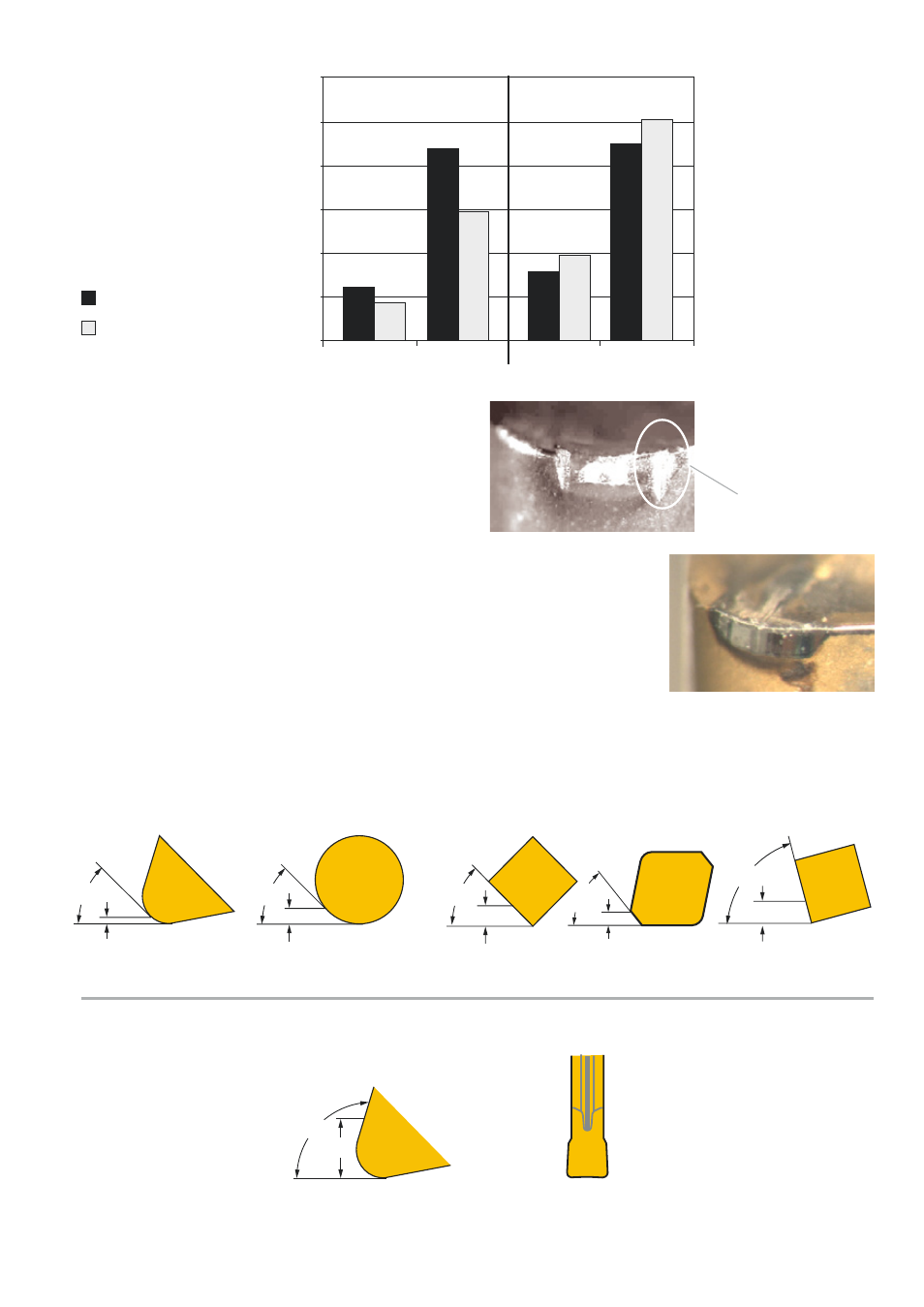

S05f h13a, Surface finish comparison – Sandvik Coromant Heat resistant super alloys User Manual

Page 29

27

CNMG/DNMG

RCMX/RO

SNMG/CNMX

SNMG

CNMG/DNMG

TF/GF

a

p

a

p

a

p

a

p

a

p

a

p

S05F

H13A

Wear causing poor

surface with worn

insert.

Surface integrity tests have shown that

S05F, applied at v

c

40 m/min, gives

extremely consistent deformation depth

and residual stress profiles, when compar-

ing new and worn inserts. The dimensional

accuracy and lack of any coning/taper is

also seen to eliminate the need for re-cut-

ting or spring passes. Both of these are the

result of minimal wear on the trailing edge

compared to other grades.

Surface roughness, Ra mm

Feed, mm/r

= New insert

= Worn insert

Surface finish

comparison

45º

GC1105 applications – notch demanding

S05F applications – PD demanding

45º

45º

75º

95º

45º

3

2.5

2

1.5

1

0.5

0

0.15

0.25

0.15

0.25

CNMG 120408-23 H13A

CNMG 120408-SF S05F