Application hints for ceramic inserts, Application hints for round inserts, Trouble shooting – wear mechanisms – Sandvik Coromant Heat resistant super alloys User Manual

Page 26

24

f

n

/2

f

n

f

n

/2

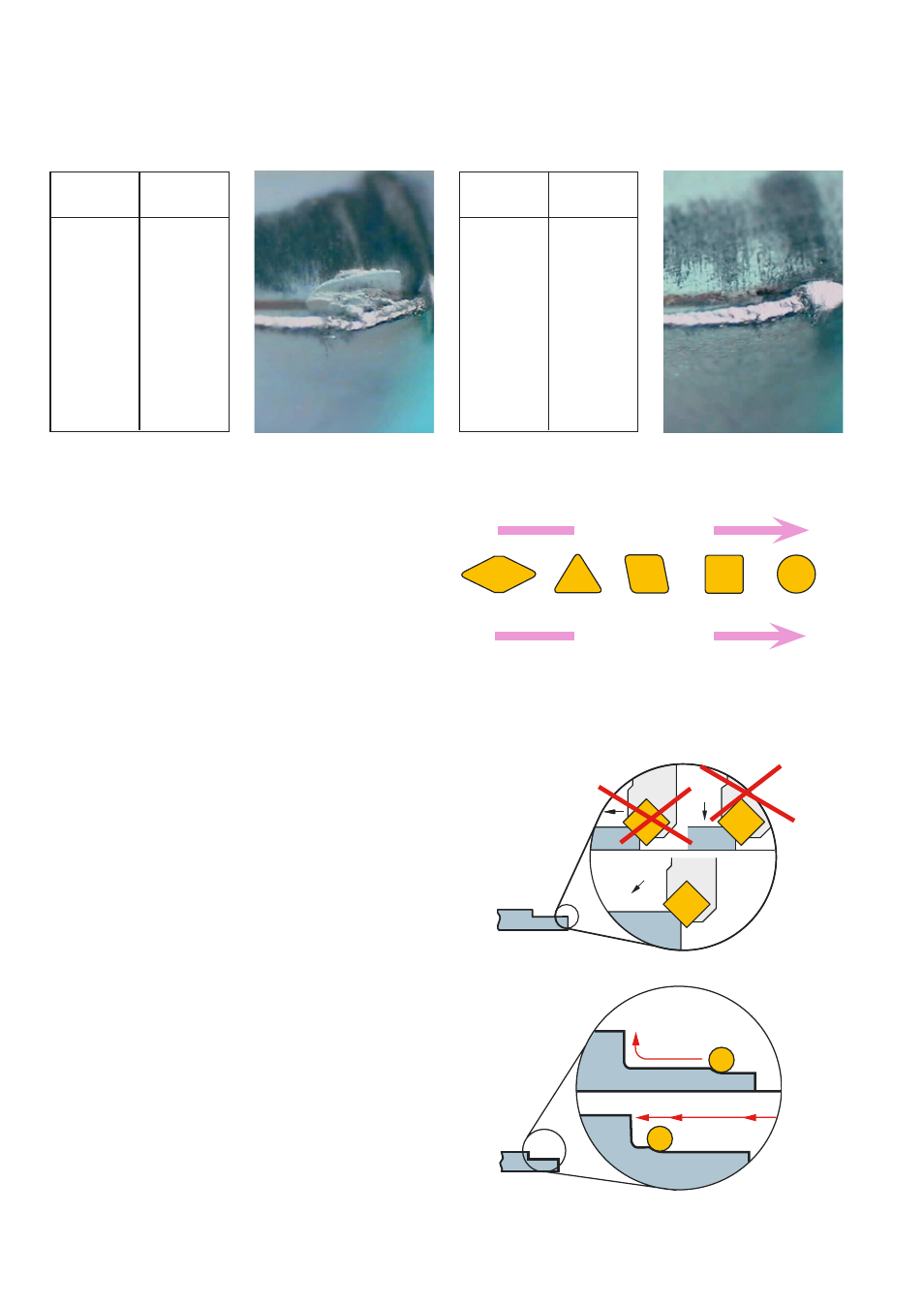

Application hints for ceramic inserts

Insert selection

• Where possible use round or square

inserts with a small entering angle and

large nose radius.

• Always use the strongest insert nose

angle.

• Thick inserts give additional strength.

Pre-chamfering

• Protects the insert when it first enters

from initial chipping/notch formation.

• To avoid notch wear when chamfering,

use a direction feed at 90° to the pro-

duced chamfer.

Turning to a shoulder either:

• Roll up to the shoulder with a radius the

size of the insert diameter to prevent

increased depth of cut.

• Reduce feed by 50% (f

n

/2) when approch-

ing a shoulder due to the depth of cut

increasing.

High

Low

Low

High

Productivity

Radial forces

Application hints for round inserts

Too high

cutting

pressure

Reason

Remedy

Top slice

Trouble shooting – wear mechanisms

Reduce

feed

Reduce a

p

on round

insert

Use

CC670

Sensitive

cutting

tool mate-

rial

Specific

to HRSA

Reason

Remedy

Notch wear

Careful

program-

ming tech-

niques

Reduce

entering

angle

Use

CC6060,

CC6065