Solid carbide – coromill plura inhrsa machining, Solid carbide – coromill®plura in hrsa machining – Sandvik Coromant Heat resistant super alloys User Manual

Page 89

87

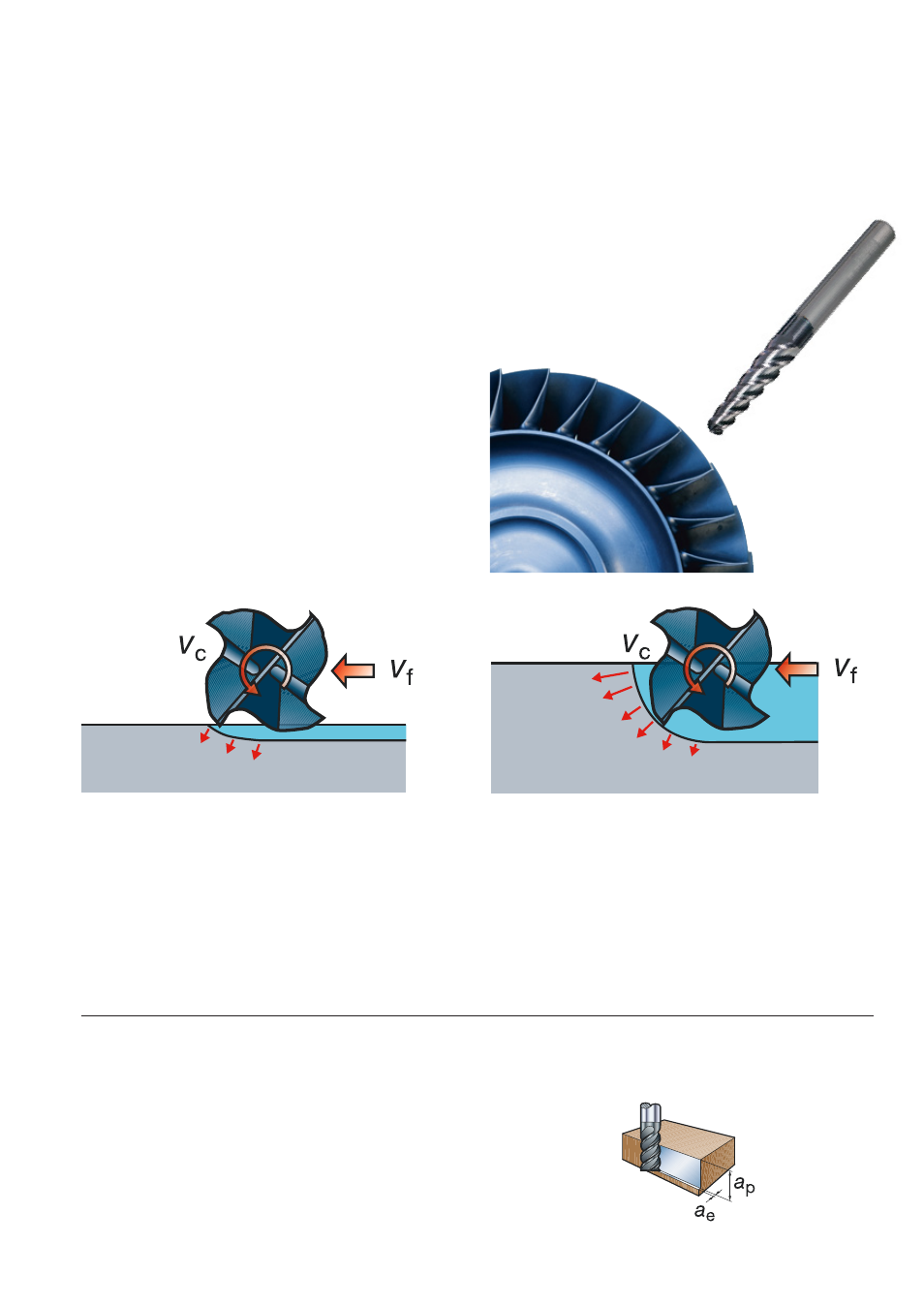

Due to the high hot hardness and tough-

ness of HRSA they are one of the most

difficult to machine materials placing great

demands on the tool. The outcome is tradi-

tionally, low cutting speeds and hence lower

productivity/higher machining costs.

High speed machining (HSM) techniques

offer an effective way to increase productiv-

ity and to mill intricate and thin-walled com-

ponents. The high feed rates do not allow

as much heat to get transferred into the

component, due to the short contact time,

compared to conventional milling tech-

niques.

However low radial cuts are required to

keep the chip thickness small and allow for

the higher feed rate.

Solid carbide – CoroMill®Plura in HRSA machining

Feed faster than heat propagation.

Traditional milling, time for heat propagation.

Factor

Thin chip thickness

Small arc of engagement

Lower cutting force/deflection

Reduced temperature at

cutting zone

Effect

Benefit

Deeper axial cuts

Higher speeds

HSM uses high rpm and axial cut (a

p

) but with only small radial engagements (a

e

) and

feed per tooth (f

z

). This is possible due to:

This method requires a machine with high

spindle speed and high feed dynamics –

putting no extra demands upon rigidity.