Typical wear recommendations, Typical wear mechanisms – Sandvik Coromant Heat resistant super alloys User Manual

Page 55

53

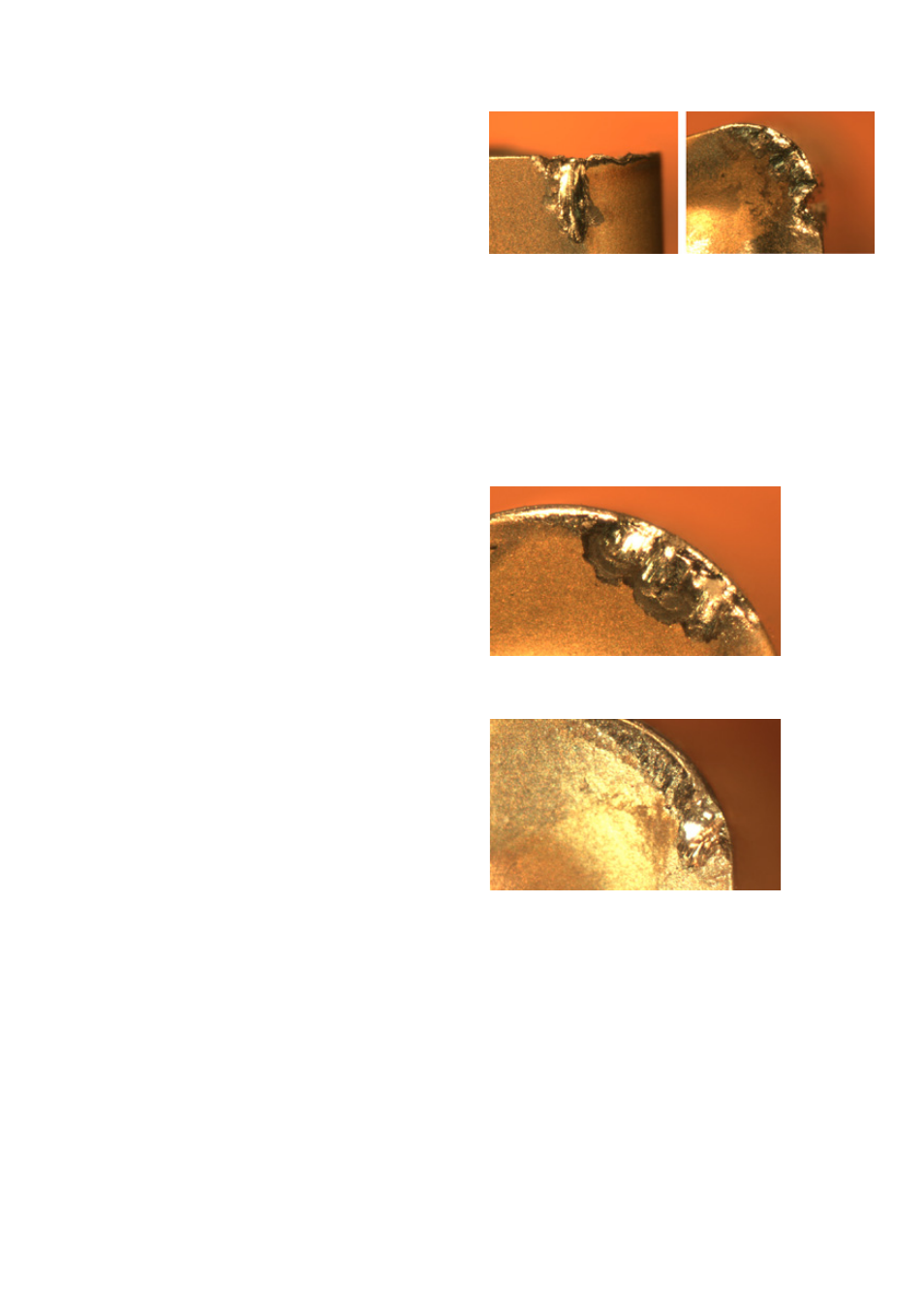

Notch wear

A mechanical wear which is concentrated at

the depth of cut. This wear reduces the tool

life drastically and produces a burr on the

component.

Remedy: It is an application related wear

which is easiest solved by changing the

entering angle (insert shape) rather than

insert grade.

Abrasive wear

Mainly caused by the hard particles in the

workpiece material rubbing or grinding the

edge.

Crater wear

Formed through the tool material being

removed from the chip face by the hard

particle grinding action.

Remedy: Select a positive insert geometry.

Reduce the speed to obtain a lower

temperature.

Typical wear mechanisms