End milling – increased immersion – Sandvik Coromant Heat resistant super alloys User Manual

Page 80

78

CoroMill

®

390

+

–

50

45

40

35

30

25

20

15

10

5

0

S30T

S30T

GC1030

S40T

GC2040

S30T

GC2040

08E-ML

08M-PM

08M-PM

08M-PL

08M-MM

08M-PL

08E-ML

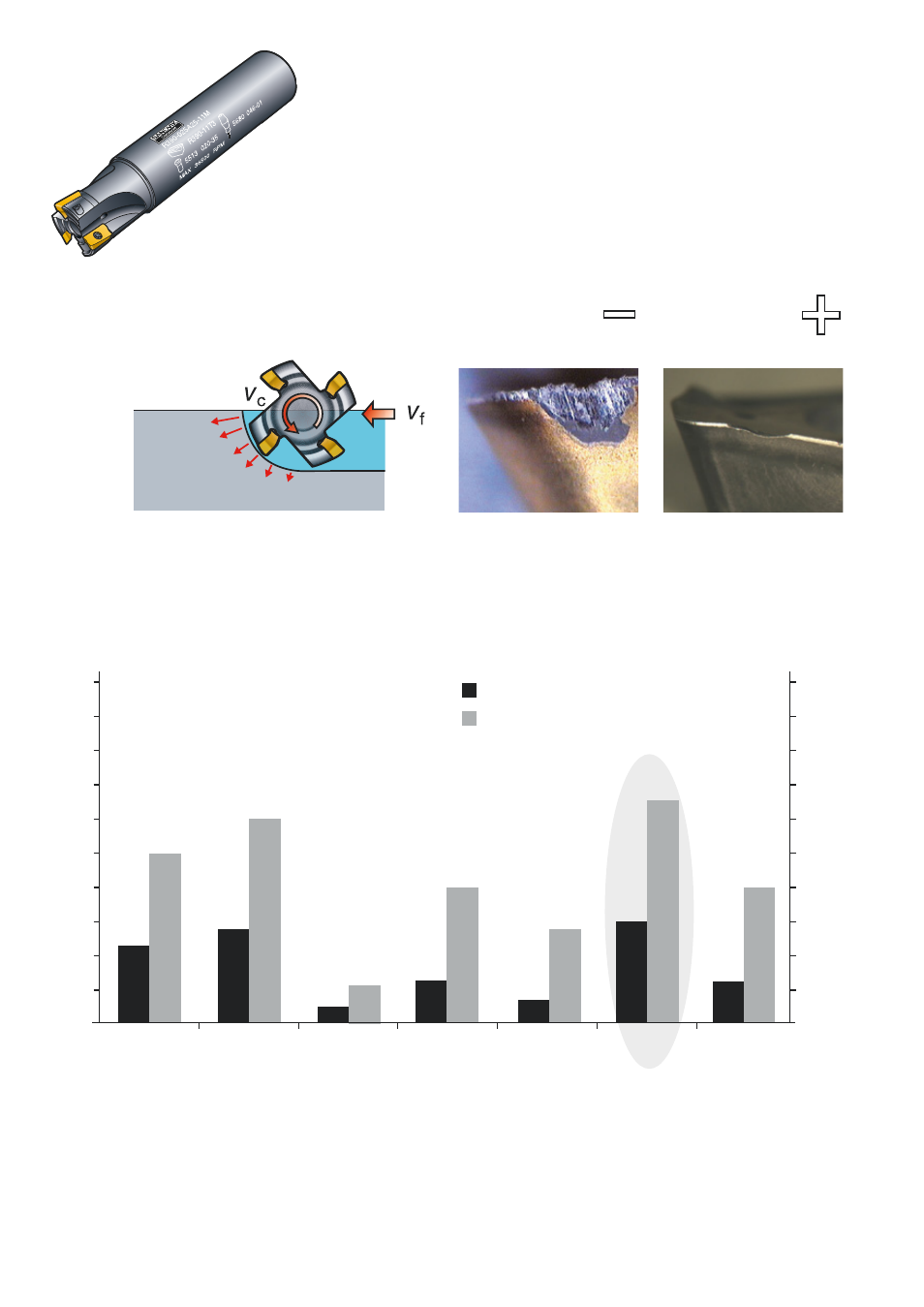

Application – increased radial immersion/extreme conditions

Tool R390-025A25-11H

z

n

4, D

c

25 mm, v

c

35 m/min, a

e

19 mm (75% of D

c

),

a

p

5 mm, h

ex

0.07 mm, f

z

0.07 mm/tooth

Material: Inconel 718 (40 HRC)

Minutes in cut

= Average time in cut

= Average volume removed

Total metal removed, cm

3

Recommendation – highest tool life and immersion ratio at 75% was achieved using insert

S30T M-PL.

Grade S30T E-PL

Grade GC1030 M-PL

End milling – increased immersion

a

e

= 25 to 75% of D

c

.

200

160

120

80

40

0