Recommended starting choices, Recommended starting choices for nickel based hrsa – Sandvik Coromant Heat resistant super alloys User Manual

Page 36

34

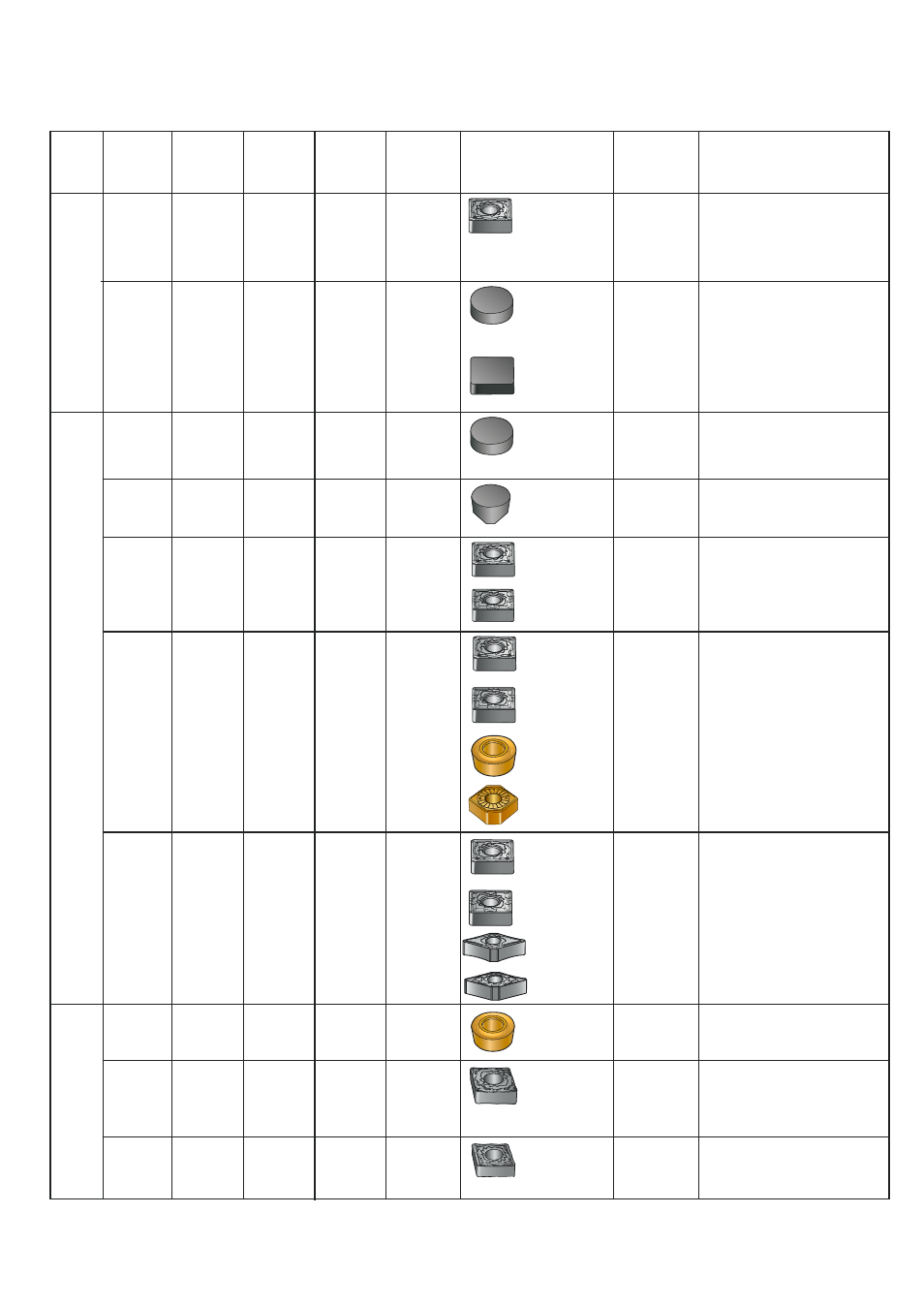

Insert style

Metal

removal rate,

cm

3

/min

Comments

Use 45° approach to

reduce chip thickness

and notching.

Use 45° approach to

reduce chip thickness

and notching – first

choice on good quality

forgings.

Use round inserts wher-

ever possible to minimize

notching.

For pocketing use

positive inserts.

Where large depths of

cut are possible.

Always use an entering

angle less than 75° if pos-

sible to reduce notching ie

Round RCMT, square

SNMG, CNMX.

For 90° entering angle.

Profiling

1st

choice

2nd

choice

Cutting

speed,

m/min

Feed,

mm/r

Depth of

cut,

mm

Use speed according

to the SCL required

for each operation.

Use the ground -SGF for

thin wall components.

Recommended starting choices for nickel based HRSA

General turning

GC1105

30–40

0.3–0.4 Up to 10

120

CC670

200

ISM

CC6060

200–300 0.1–0.2 1 to 3

120

CC6060

200–250 0.1–0.2 1 to 3

80

GC1105 40–60

0.3–0.45 3 to 5

90

GC1105 40–60

0.2–0.45 1 to 3

50

0.2–0.35 1 to 3

50

0.2–0.5

1 to 3

50

40–60

0.15–

0.25

1 to 3

25

150–200 0.15–0.2 Up to 5

0.25–0.5

LSM

GC1105 40–60

0.25 to

0.5

40–80

0.15

0.25

S05F

40–60

0.15

0.25

GC1105

GC1105

GC1115

CC6065

CC6065

S05F

S05F

GC1105

S05F

CC6065

SNMG 15,

19 -SMR

RNGN 19

SNGN 19

RNGN 12

RPGX

SNMG 15,

19 -SMR

RCMT -SM

CNMX -SM

RCMT -SM

*NMG -SF

*NGG -SGF

FSM

GC1105 40–60

0.25–

0.35

3 to 5

90

S05F

SNMG 15,

19 -SM

GC1115

GC1115

SNMG -SMR

SNMG -SM

DNMG -SM

SNMG -SM

0.2–0.35 1 to 2.5

50

SNMG -SMR

DNMG -SMR