Circular ramping from solid, Circular milling from predrilled hole – Sandvik Coromant Heat resistant super alloys User Manual

Page 115

113

16

26

20

34

25

44

R390-11T331E-ML 2040

2

30

0.10

32

58

40

74

25

38

32

52

34

56

35

58

40

68

42

72

R300-1240E-MM 2040

2

30

0.20

50

88

52

92

63

114

66

120

80

148

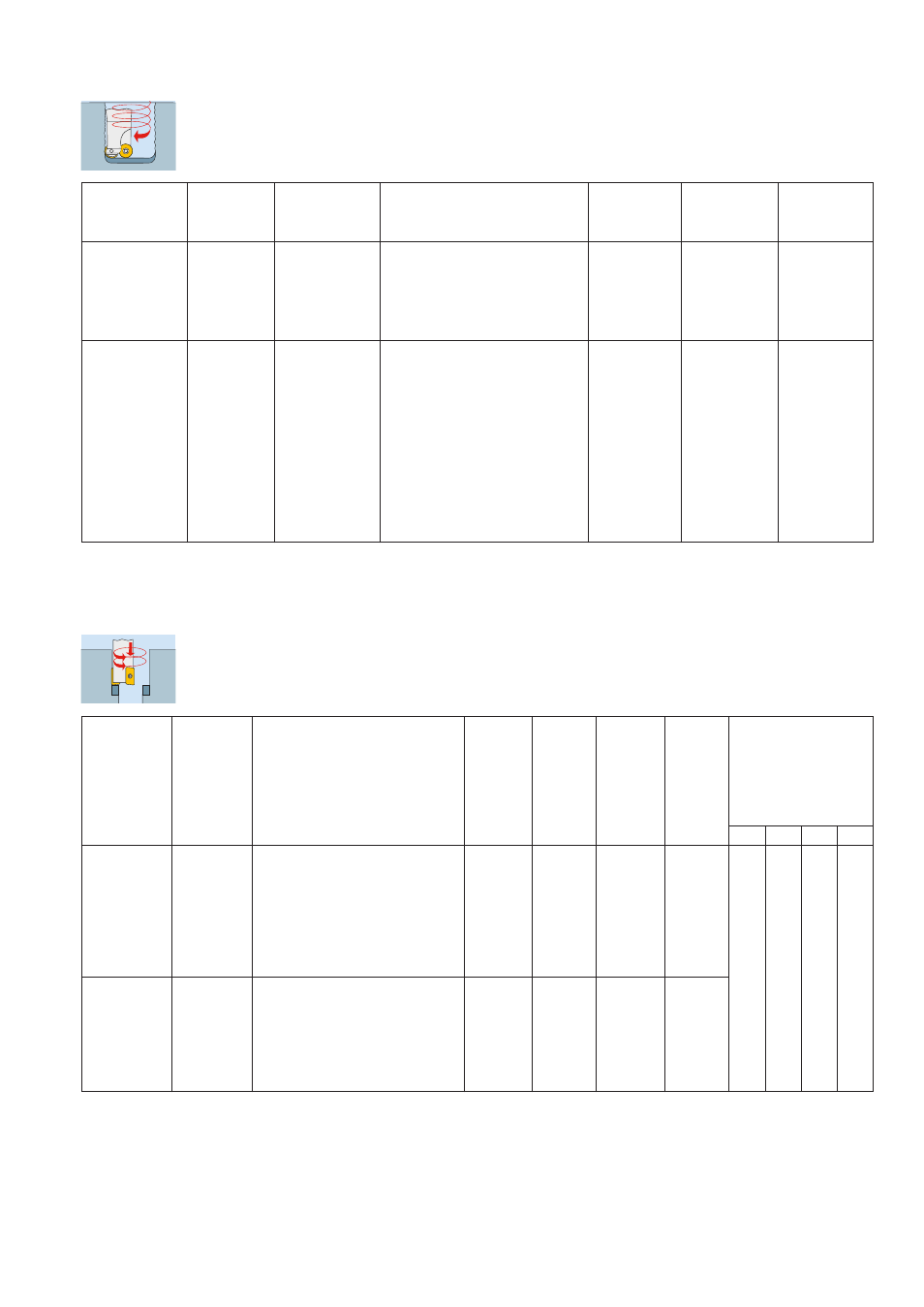

Circular ramping from solid

Insert choice

Cutting speed

v

c

m/min

Feed* f

z

mm/tooth

Max. depth

of cut/pitch

a

p

mm

Cutter

diameter

Cutter

concept

CoroMill

®

390

end mill

Min. hole dia.

D

m min

mm

CoroMill

®

300

*Reduce feed when programming tool centre feed.

80% 60% 40% 20%

CoroMill

®

Plura

4

5

R216.23-04050CAK11P 1620

4

0.3

5

6.25 R216.23-05050CAK13P 1620

5

0.4

6

7.5

R216.24-06050CAK13P 1620

6

75

0.5

0.08

8

10

R216.24-08050EAK19P 1620

8

0.6

10

12.5

R216.24-10050EAK22P 1620

10

0.8

7.6 3.4 2 1.4

12

15

R216.24-12050GAK26P 1620

12

1.0

CoroMill

®

390

16

20

R390-11T308M-PM 1030

2.0

20

25

2.5

25

31

10

30

3.1

0.1

32

40

4.0

40

50

5.0

Circular milling from predrilled hole

Tool choice

Cutting

speed v

c

m/min

Feed* f

z

mm/

tooth

Optimal

radial cut

a

e

mm

Min. hole

dia. D

c

=

80% D

m

D

m

mm

Cutter dia.

D

c

mm

Max.

depth of

cut/pitch

a

p

mm

*Reduce feed when programming tool centre feed.

Feed reduction

factor when using

tool centre feed:

cutter dia. relative

to hole D

c

/D

m