Effect of chip thickness, h – Sandvik Coromant Heat resistant super alloys User Manual

Page 81

79

50

40

30

20

10

0

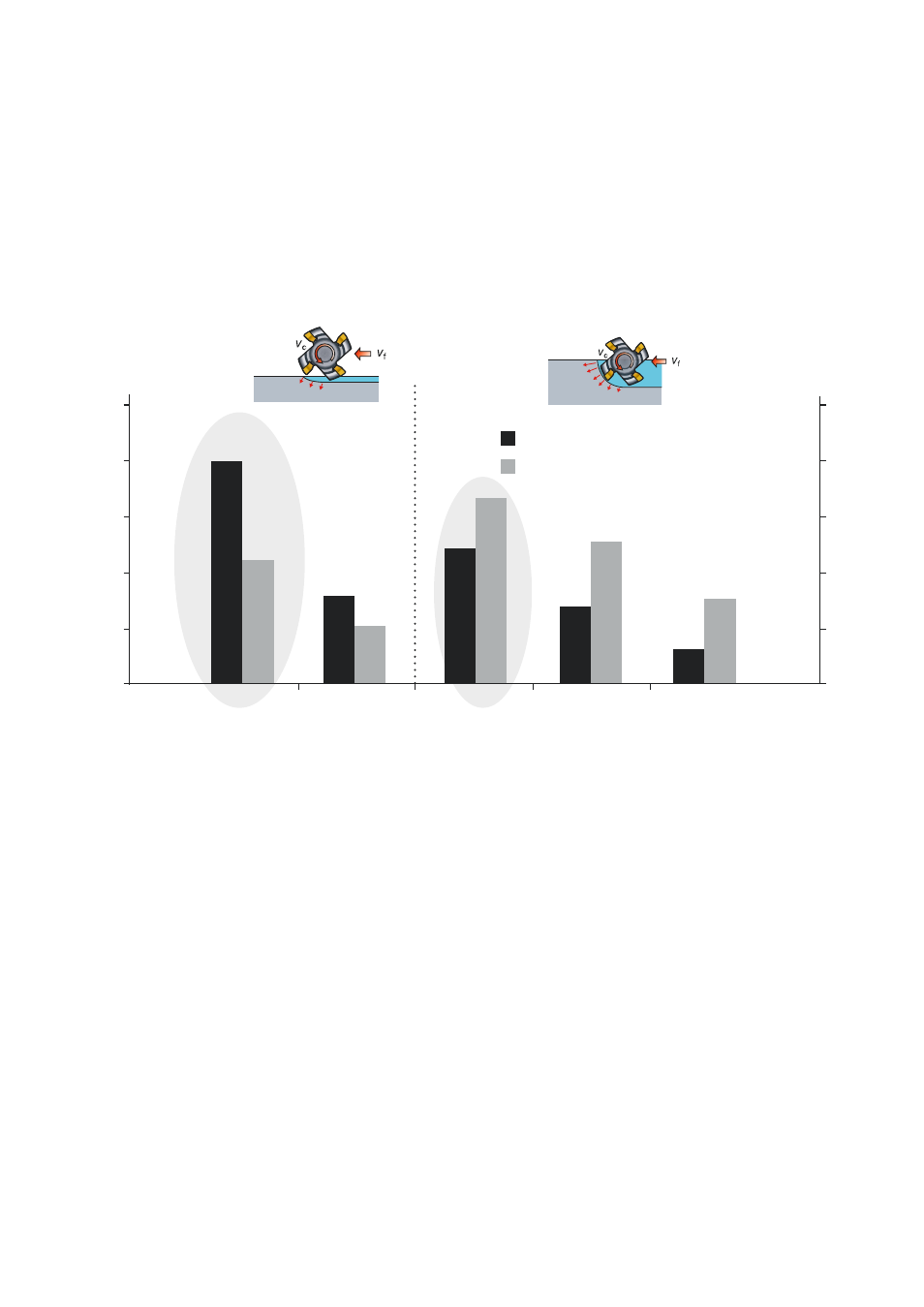

Effect of chip thickness, h

ex

Tool R390-025A25-11H

z

n

4, D

c

25 mm, v

c

25 m/min, a

p

5 mm,

Material: Inconel 718 (44 HRC)

Recommendation

For low radial immmersion, grade/geometry S30T E-ML chip thickness 0.07 mm.

For increased radial immersion, grade/geometry S30T E-ML chip thickness 0.07 mm.

Minutes in cut

h

ex

0.07 mm

h

ex

0.13 mm

h

ex

0.07 mm

h

ex

0.1 mm

h

ex

0.13 mm

f

z

0.11 mm/tooth f

z

0.20 mm/tooth f

z

0.07 mm/tooth f

z

0.1 mm/tooth f

z

0.13 mm/tooth

a

e

3.1 mm (12.5% of D

c

)

a

e

12.5 mm (50% of D

c

)

S30T E-ML

S30T E-ML

= Average time in cut

= Average volume removed

Total metal removed, cm

3

200

160

120

80

40

0