Chip thickness, Surface finish, Example – Sandvik Coromant Heat resistant super alloys User Manual

Page 21

19

f

n

h

ex

k

r

f

n

iC

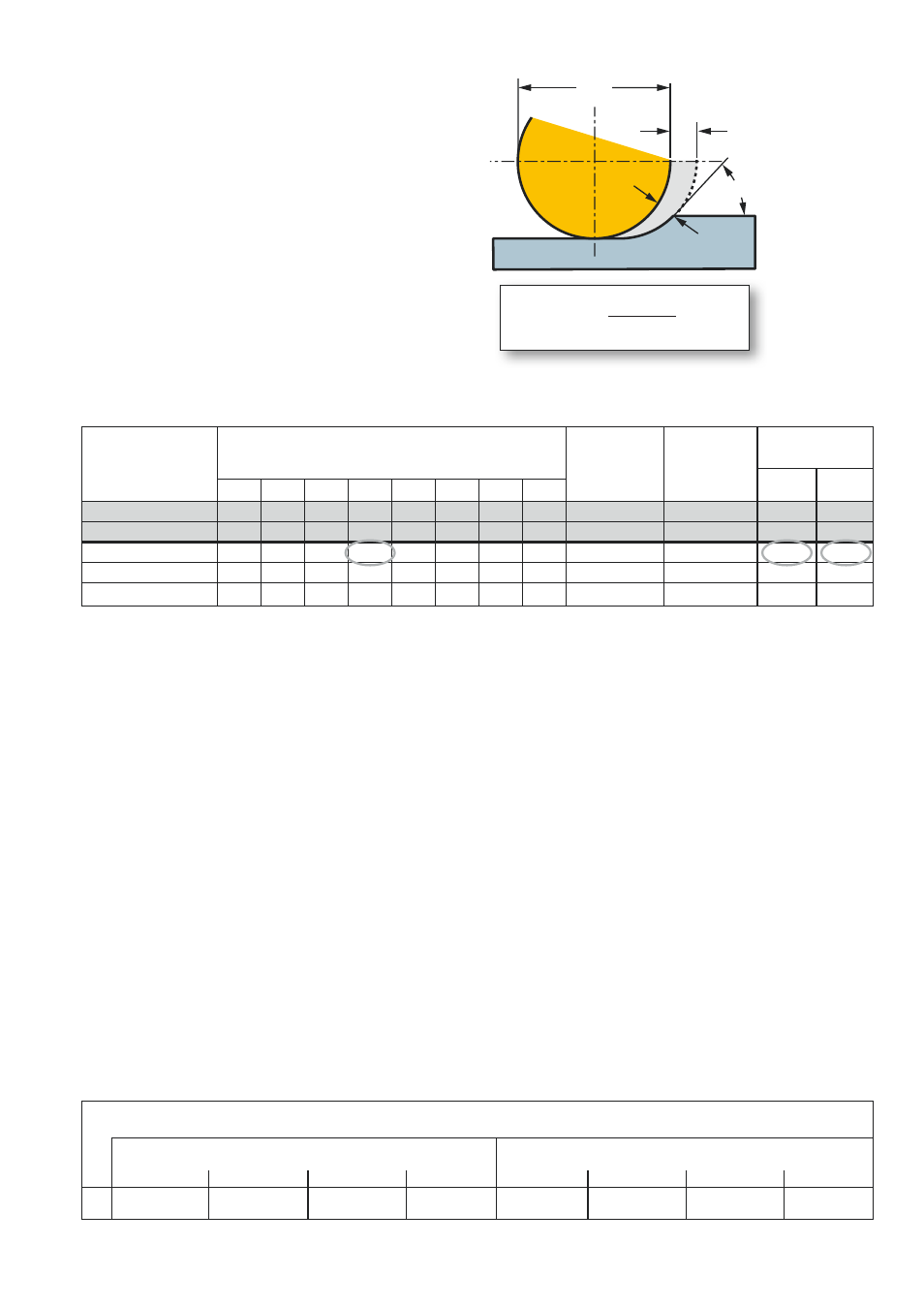

Chip thickness

The chip thickness varies with round

inserts, and depends upon the entering

angle. With low a

p

/iC ratios, the feed can

be increased in order to raise the chip

thickness to a desired level.

Recommended chip thicknesses h

ex

for

HRSA are:

Carbide

0.1 to 0.35 mm

Ceramic

0.08 to 0.15 mm

Depth of cut to

diameter ratio

a

p

/iC

Depth of cut for insert diameter, in mm

Entering

angle

k

r

Feed modi-

fication

value

Feed min/max

mm/r

h

ex

0.1

mm

h

ex

0.35

mm

6 mm diameter CoroCut RO insert.

Depth of cut 0.9 mm gives a maximum

entering angle

k

r

= 46°.

To machine with:

Minimum 0.1 mm chip thickness the cor-

rect feed is 0.14 mm/r.

Maximum 0.35 mm chip thickness the

correct feed is 0.49 mm/r.

The surface finish generated has a direct

relationship to both the nose radius size

and the feed rate. To achieve a certain

surface finish, a small nose radius requires

a lower feed rate than a large nose radius

– which in practical terms means that small

nose radius inserts lead to lower productiv-

ity.

Therefore, for the highest productivity the

nose radius should be as large as possible

– the largest of all being round inserts.

Nose radius size mm

Insert diameter mm

Maximum feed f

n

mm/r to achieve surface finish R

max

8.0 – R

a

1.6 µm – N7

Example

Surface finish

f

n

=

h

ex

sin

k

r

3

4

5

6

8

10

12

16

0.25

0.75

1

1.25 1.5

2

2.5

3

4

60°

1.16

0.12

0.41

0.2

0.6 0.8

1

1.2 1.6

2

2.4 3.2

53°

1.25

0.13

0.44

0.15

0.45 0.6 0.75 0.9 1.2 1.5 1.8 2.4

46°

1.4

0.14

0.49

0.1

0.3 0.4 0.5 0.6 0.8

1

1.2 1.6

37°

1.66

0.17

0.58

0.05

0.15 0.2 0.25 0.3 0.4 0.5 0.6 0.8

26°

2.3

0.23

0.81

0.4

0.8

1.2

1.6

8

10

12

16

0.17

0.22

0.27

0.32

0.5

0.57

0.62

0.7