Scl recommendations, Lsm/finishing – Sandvik Coromant Heat resistant super alloys User Manual

Page 31

29

B

B

B

C

D

E

E

A

A

B

B

B

C

D

E

E

CNGG 120408-SGF 1105

CNMG 120408-SF 1105

CNMG 120408-SF S05F

CNMG 120408-SM 1105

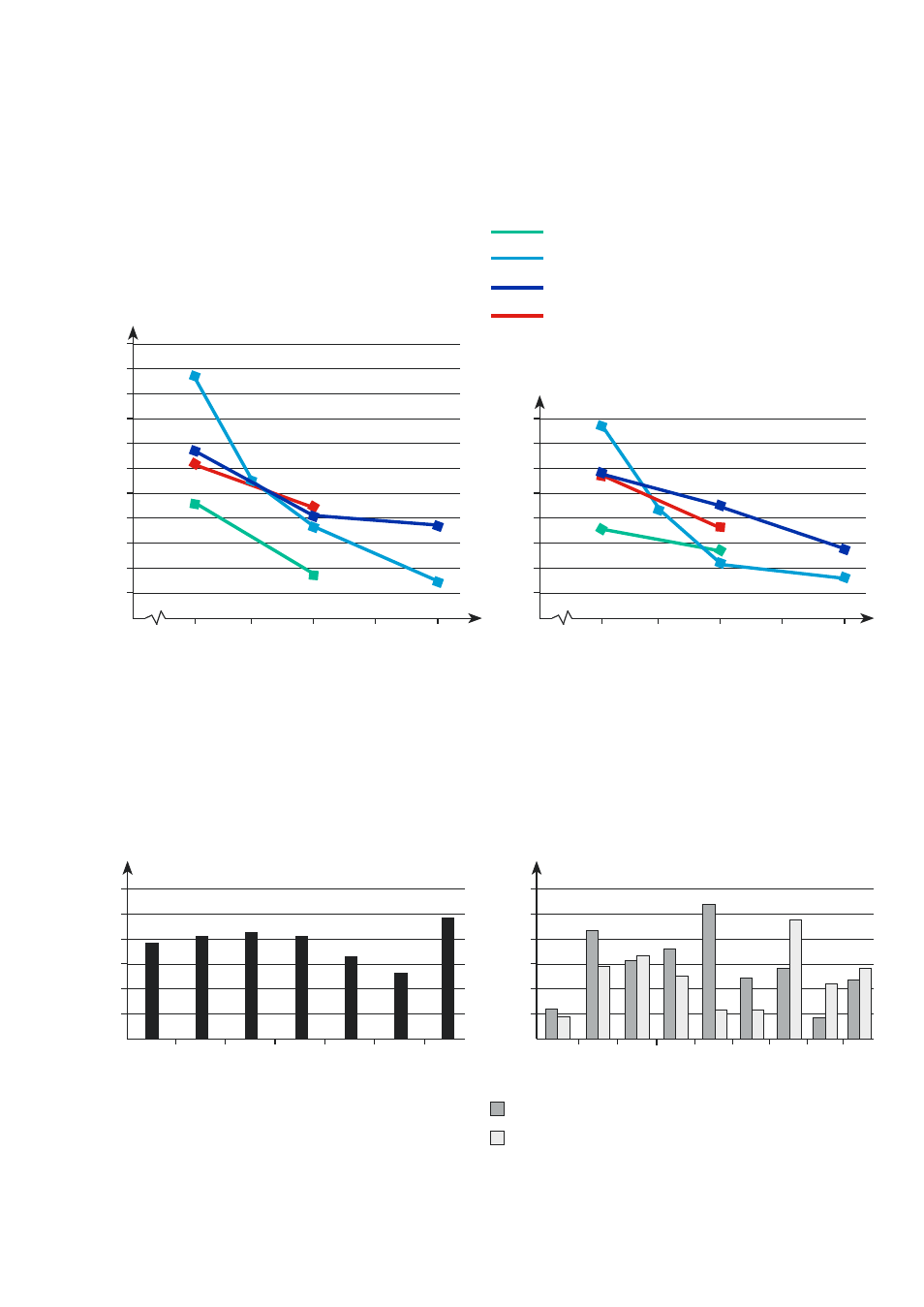

SCL recommendations

All cutting trials for these data recommendations are in Inconel 718 (46 HRC) and

have been found to be true for other nickel alloys in the same hardness – Udimet 720,

Waspaloy.

SCL

m

Cutting speed m/min

a

p

0.25 mm – f

n

0.15 mm/r

a

p

0.25 mm – f

n

0.25 mm/r

SCL

m

Cutting speed m/min

LSM/finishing

SCL for CoroCut RO geometry S05F –

a

p

0.25 mm – f

n

various

SCL

m

Feed mm/r

= New

= Worn

Surface finish

R

a

Feed mm/r

Surface finish for

radius size

A = CNMG 120408-SF S05F

B = N123H2-0400-RO S05F

C = N123J2-0600-RO S05F

D = N123L2-0800-RO S05F

E = RCMT 1204M0-SM S05F

2750

2500

2250

2000

1750

1500

1250

1000

750

500

250

0

40

60

80

2000

1750

1500

1250

1000

750

500

250

0

40

60

80

1200

1000

800

600

400

220

0

0.25 0.3

0.36 0.36 0.42 0.25 0.5

3

2.5

2

1.5

1

0.5

0

0.15 0.25 0.25 0.3 0.36 0.36 0.42 0.25 0.5