Back chamfering/deburring, Programming sequence method – Sandvik Coromant Heat resistant super alloys User Manual

Page 111

109

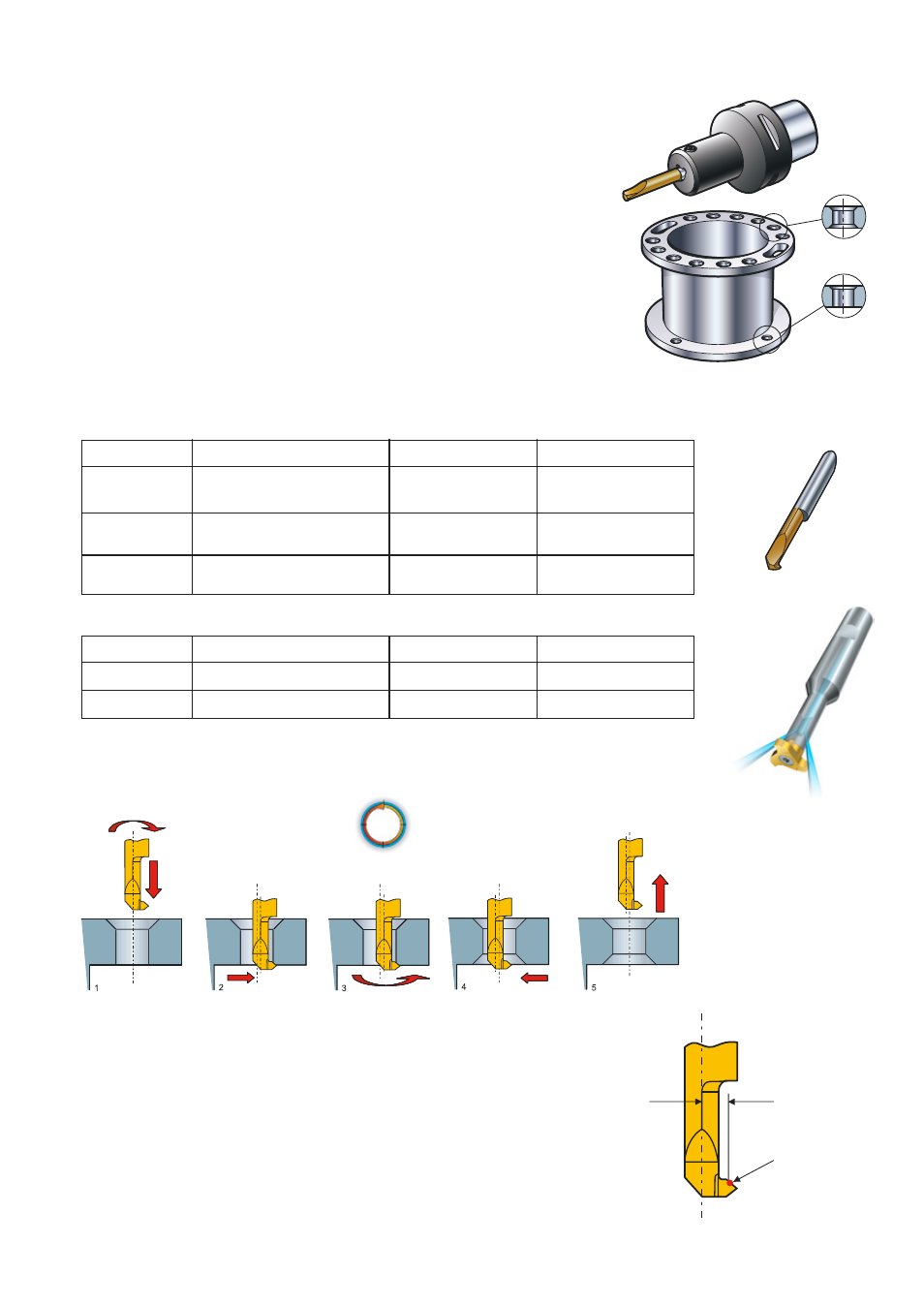

CoroMill®327

CoroTurn®XS

1.

Position the cutter

centrally over the drilled

hole with the cutter

rotating (v

c

75) and

move axially to flange

depth (Z = flange height

– chamfer size).

2. Feed cutter to engage

with radius compensa-

tion (Y = hole radius).

3.

Interpolate 360° (fz 0.1

mm).

4.

Feed back to hole

centre.

5.

Retract cutter.

Programming sequence method

Adaptor

Insert

Min hole size

Max hole depth

When machining aerospace engine components, one

tricky but often neglected operation is deburring holes.

By using a CoroMill 327 or CoroTurn XS back chamfering

tool it is possible to increase productivity while providing

a repeatable, mechanised, safe process – eliminating the

need for manual deburring and special tools.

The CoroTurn XS tool must be used with a Coromant

Capto adaptor to provide the correct clearance when used

in rotating applications.

Offset point

for tool length

and radius.

Back chamfering/deburring

Size

Insert

Min hole size

Max hole depth

06

327R06-12045-CH

11.7

40

12

327R12-20045-CH

21.7

85

C4-CXS-47-05 CXS-05T045-20-5215R

7

15

CXS-05T045-20-5220R

20

C4-CXS-47-06 CXS-06T045-20-6220R

8

20

CXS-06T045-20-6225R

25

C4CXS-47-07 CXS-07T045-20-7220R

9

20

CXS-07T045-20-7240R

40