Sandvik Coromant Heat resistant super alloys User Manual

Page 37

35

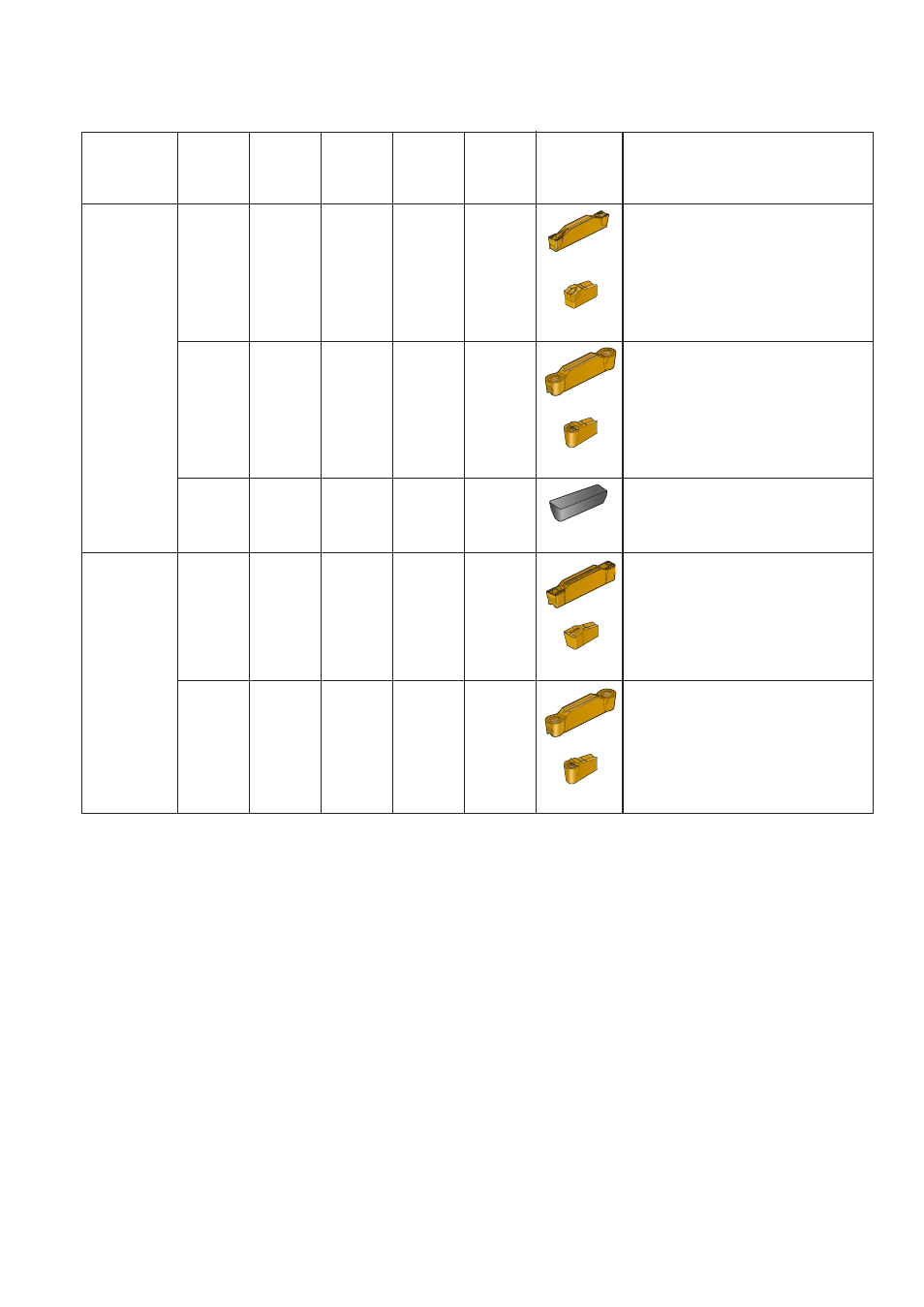

Grooving and profiling

GC1105 GC1125 40– 60 0.1–0.15

TF

5E

S05F

GC1105 40– 60 0.2–0.4

RO

4P

CC670

200–400 0.05–0.1

150.23

GC1105 GC1125 40– 60 0.1–0.15

GF

4G

S05F GC1105 40– 60 0.15–0.35

RO

4P

ISM

LSM

Machining

stage

1st

choice

2nd

choice

Cutting

speed,

m/min

Feed,

mm/

rev

Depth

of cut,

mm

Insert

style

Comments

For rough grooving - use largest

rad possible.

For profiling.

For rough grooving under good

conditions.

For finish grooving.

Use 0.4 radius where possible.

For finish profiling.

Max a

p

0.15 x D

0.25 to

0.5

0.25 to

0.5