Process considerations – Sandvik Coromant Heat resistant super alloys User Manual

Page 54

52

Component condition

The forgings are manufactured from cast-

ings or bar stock. This has some impact on

the process, whilst the cast blank has less

material to remove, the tough skin, with a

certain degree of ovality, can cause difficul-

ties if the insert is not fully engaged on the

first pass. Bar stock requires much more

material to be removed and normally there

is a drilling operation to remove the bulk,

see engineered solution page 58.

Machining limitations

The process method and productivity are

limited by the poor machinability of the

material, difficult to access the internal

sphere and also weak fixturing. Normally

the casting has a spigot for fixturing whilst

machining the internal feature, this spigot

is later removed.

Machining stage – classification

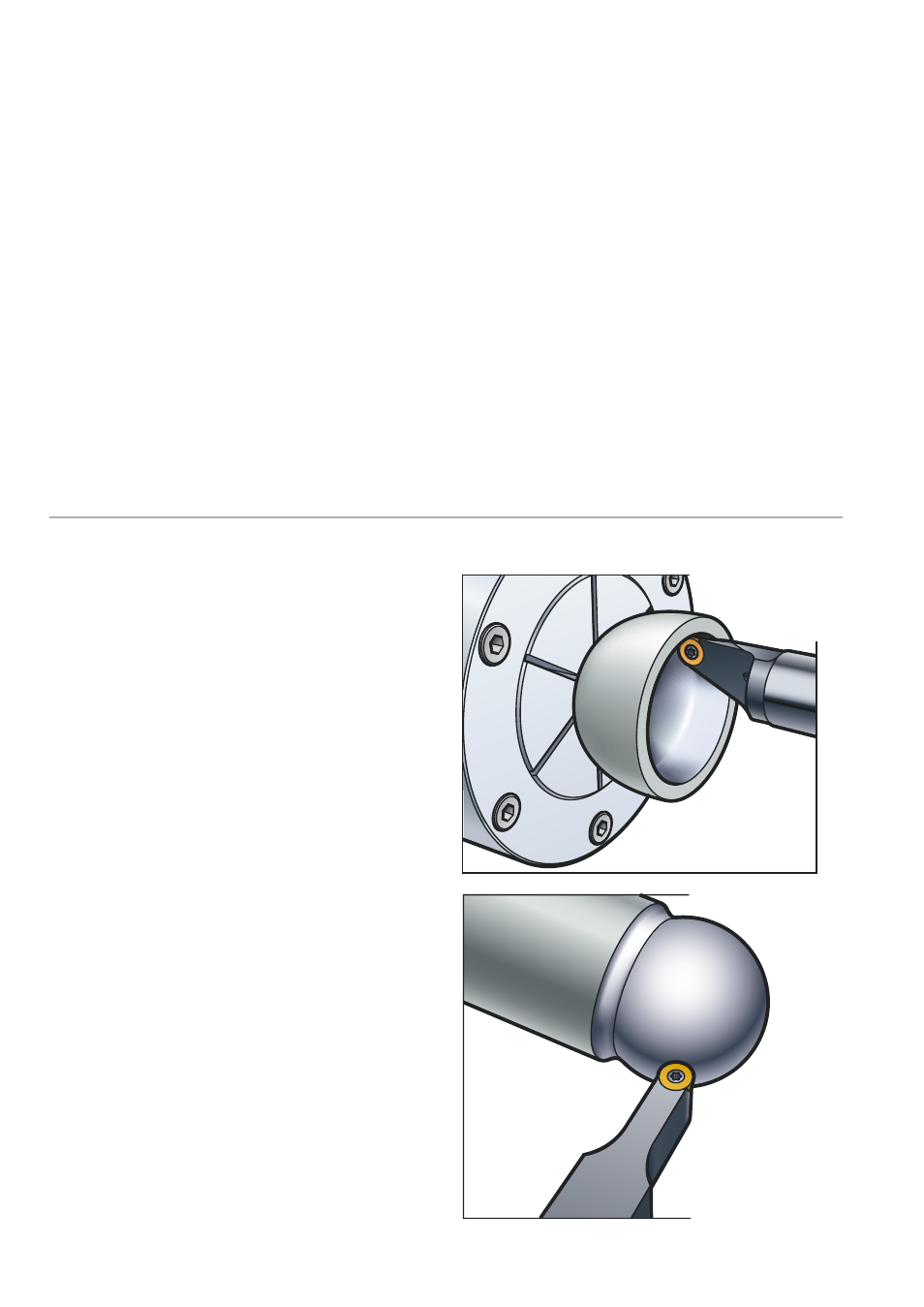

Process/operation 1 – Internal cup

• Rough drilling – bar stock.

• Rough turning – up to 1 mm depth of cut.

• Semi-finish turning – 0.1–0.15 mm depth

of cut.

• Finish turning – 0.05–0.15 mm depth of

cut.

• Part off spigot.

Process/operation 2 – External head

• Rough turning – up to 1 mm depth of

cut.

• Semi-finish turning – 0.1–0.25 mm depth

of cut.

• Finish turning – 0.05–0.15 mm depth of

cut.

• Part off – bar stock.

Process considerations