Engineered solutions, Engineered solutions for the aerospace industry, Corocut®angled inserts for grooving – Sandvik Coromant Heat resistant super alloys User Manual

Page 39

37

Order finished ground engineered inserts

according to your specific requirement:

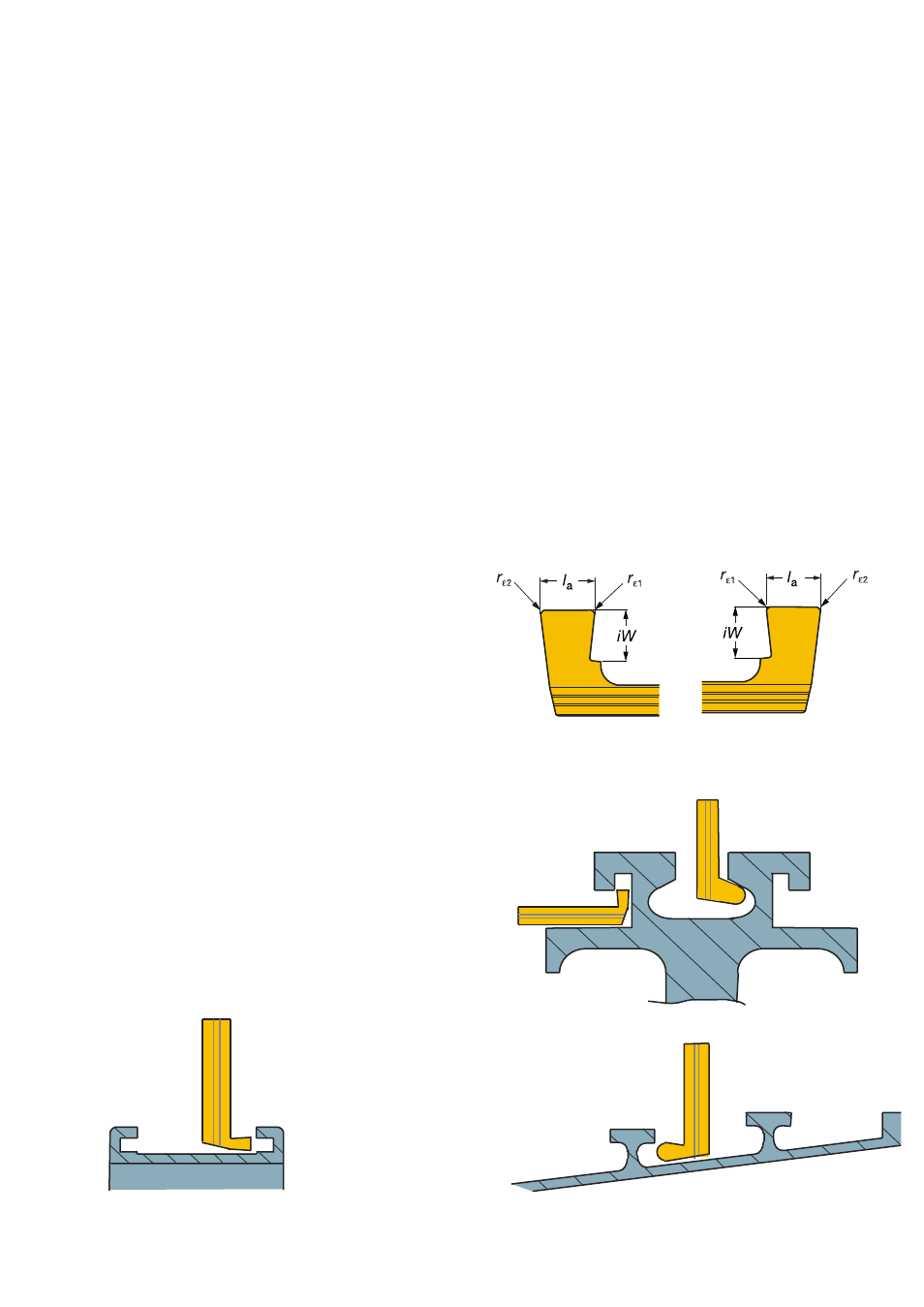

Width l

a

Depth iW

Radii rε

1

, rε

2

Chipformers

Width/depth limitations

Available grades:

GC1105 – first choice for HRSA

applications

H13A

– for interrupted cuts

Left hand

Right hand

Typical features/applications are found

in casings, discs, rings and shafts

Vane/stator segment

Casing

Disc, shaft

Engineered solutions for the aerospace industry

We have developed engineered solutions to specific application requirements in the aero-

space industry. The solutions will be developed to a specific component – contact your

Sandvik Coromant technical representative for more details.

CoroCut®angled inserts for grooving

Thin walls and complex shapes for components in the aero engine leads to a requirement

for grooving and profiling inserts within tightly confined spaces. Standard inserts and tool

holders often do not offer the combination of sufficient accessibility and rigidity, which is

required in tough-to-machine materials.

To overcome these obstacles Sandvik Coromant has developed engineered inserts, which

utilise the outstanding stability of the CoroCut tip seat design and optimized grades provid-

ing security and productivity.