Insert shape selection – Sandvik Coromant Heat resistant super alloys User Manual

Page 56

54

iC

k

r

a

p

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

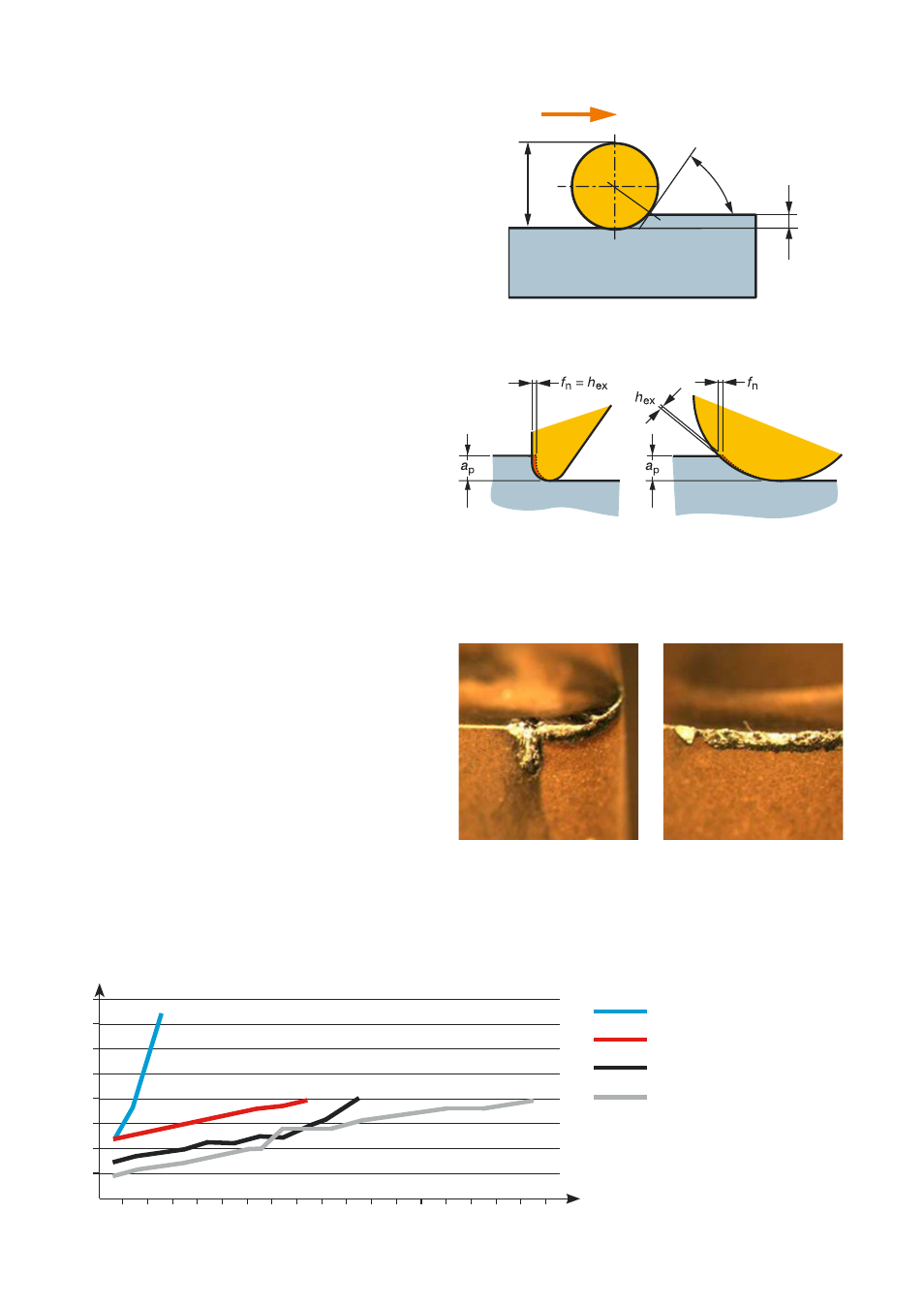

From the wear mechanisms it can be seen

that a reduction in entering angle (

k

r

) has

two clear advantages:

• Notch wear reduced giving longer more

predictable wear with improved pro-

ductivity.

• Reduced chip thickness – with a V or D

style insert the chip thickness (h

ex

) is the

same as the feed and the cutting length

is the same as the depth of cut. Using

a depth of cut below the radius reduces

the chip thickness relative to feed and

increases the cutting edge length. These

give the end result of lower temperature

and hence longer cutting length and high

productivity capability.

A reduction in entering angle without reduc-

ing the depth of cut is best achieved by

using a large radius – in practical terms a

round insert.

The diagram below shows the effect of the

nose radius on tool life. An increase of 6

fold with the same grade.

Wear,

mm

Time in cut,

min

Material CoCr28Mo6, v

c

50 m/min, f

n

0.15 mm/r,

a

p

1 mm (CNMG 1204xx-QM 1105)

Nose radius 0.8 mm

Nose radius 1.2 mm

Nose radius 1.6 mm

Nose radius 3.2 mm

Tool life: 3 min.

Radius: 0.8 mm

Tool life: 18 min.

Radius: 3.2 mm

Effect of nose radius

Insert shape selection

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0