Recommended start cutting data, Face milling, Side milling – Sandvik Coromant Heat resistant super alloys User Manual

Page 104: Closed slot milling

102

CoroMill

®

300

R300-0828E-PL GC1030

1

30

0.18

R300-1240E-PL G1030

2.5

30

0.25

R300-1240E-MM GC2040

2.5

25

0.25

R300-1648E-MM GC2040

4

70% of D

c

25

0.30

CoroMill

®

245

k

r

45°

R245-12T3E-ML GC2040

3

30

0.20

CoroMill

®

390

k

r

90°

R390-11T308E-ML GC2040

5

30

0.10

Face milling

Tool choice

Cutting speed

v

c

m/min

Feed f

z

mm/tooth

Recommended start cutting data

Max. depth

of cut a

p

mm

Application

Type

Round

Low to

medium a

p

Medium to

large a

p

Against

shoulder

CoroMill

®

390 end mill

16–40

R390-11T308M-PL GC1030

8

12.50%

35

0.10

16–40

R390-11T308E-ML GC2040

8

50–75%

35

0.07

25–40

R390-17408M-PL GC1030

14

12.50%

35

0.10

25–40

R390-17408E-ML GC2040

14

50–75%

35

0.07

CoroMill

®

Plura

6–20

R216.24-xx050-AKxxP GC1620

2 x D

c

8%

75

0.04

6–20

R216.24-xx050-AKxxP GC1620

2 x D

c

Side milling

Tool choice

Cutting speed v

c

m/min

Max. chip thick-

ness h

ex

mm

Max. depth of cut

a

p

mm

Radial cut

a

e

/D

c

Cutter dia. D

c

mm

CoroMill

®

390

16–40

R390-11T308E-ML GC2040

8

25–35

0.10

25–40

R390-170408E-ML GC2040

14

25–35

0.10

CoroMill

®

Plura

6–20

R216.24-xx050-AKxxP GC1620

0.5 x D

c

75

0.05

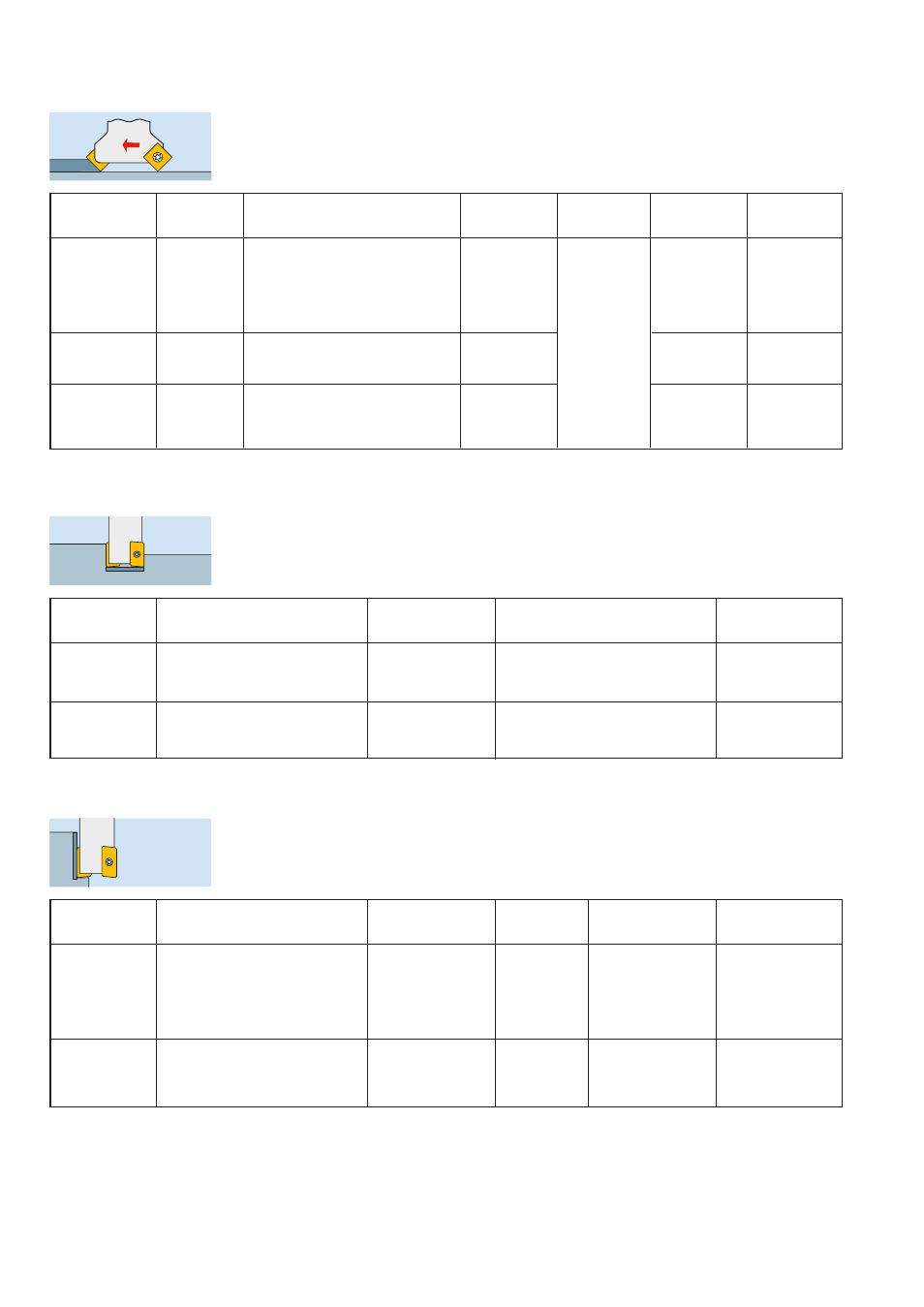

Closed slot milling

Tool choice

Cutting speed v

c

m/min

Feed f

z

mm/tooth

Max. depth of cut

a

p

mm

Cutter dia. D

c

mm

Radial cut

a

e

mm