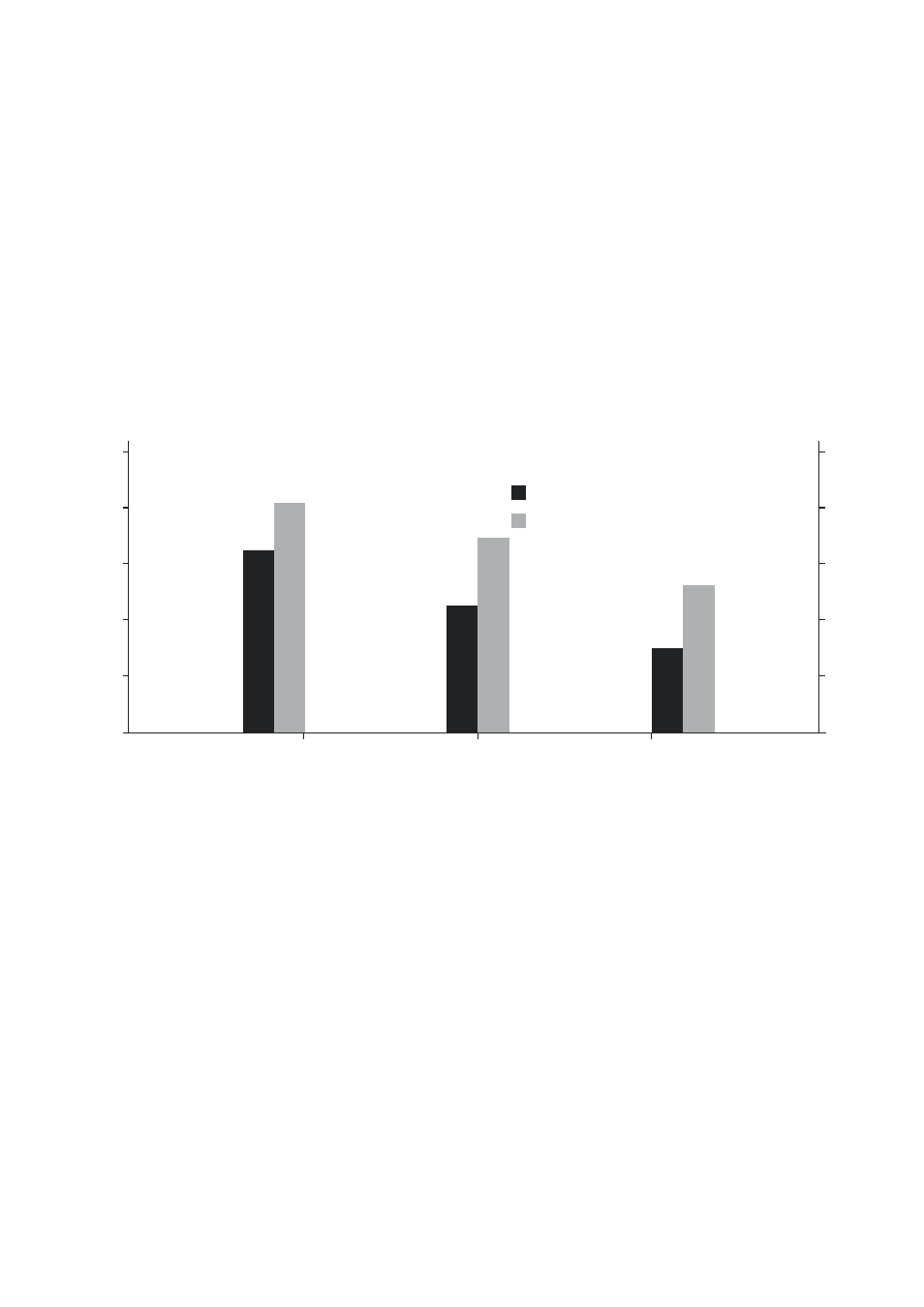

Effect of cutting speed, v, 35 m/min s40t max v, 30 m/min complementary: s30t max v – Sandvik Coromant Heat resistant super alloys User Manual

Page 73: 30 m/min

71

20

16

12

8

4

0

Effect of cutting speed, v

c

Tool R300-063Q22-12H, insert R300-1240 E-PL S40T

z

n

7, D

c

51 mm, a

e

36 mm, a

p

2 mm,

f

z

0.24 mm/tooth, h

ex

0.18 mm,

Material: Inconel 718 (44 HRC)

Minutes in cut

= Average time in cut

= Average volume removed

Surface speed together with the material

hardness are the most important factors in

determining tool life when machining super

alloys. Cutting temperatures for HRSA mate-

rials are typically 750 to 1020ºC. These

temperatures are sufficiently high that oxi-

dation and work-hardening become contrib-

uting factors to total tool wear.

The results below show that an increase

of 5 m/min cutting speed reduces tool

life and total material removed by approxi-

mately 30%.

Total metal removed, cm

3

Recommendation - for roughing using carbide inserts, speeds should not exceed (harder

material choose the lower value):

First choice:

GC1030 max v

c

30-35 m/min

S40T max v

c

25-30 m/min

Complementary:

S30T max v

c

30-35 m/min

GC2040 max v

c

25-30 m/min

250

200

150

100

50

0

v

c

25 m/min

v

c

30 m/min

v

c

35 m/min