Sandvik Coromant Heat resistant super alloys User Manual

Page 78

76

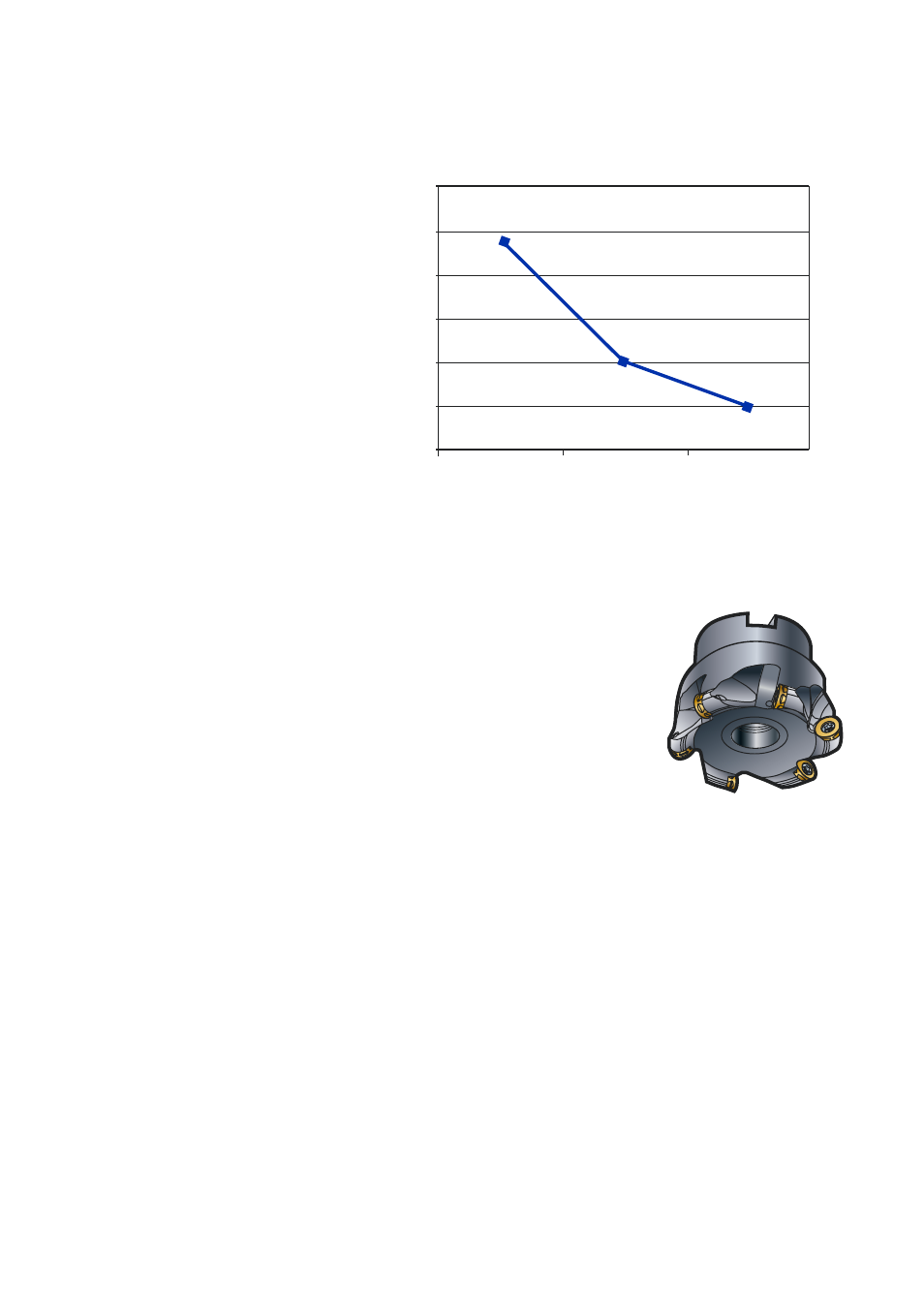

CoroMill® 300

30

25

20

15

10

5

0

40

43

46

HRC

R300-1240E-MM 2040

• CoroMill 300 (round insert cutter) gives optimum performance.

• Grade S40T/GC1030 has the best performance.

• Use E-MM/E-PL geometry except at the highest chip loads

(>0.3 mm/tooth) where M-MH offers better edge strength.

• Increase in cutting speed reduces tool life significantly;

25 m/min offers the best balance of tool life and productivity.

• Close pitch cutters with through spindle coolant supply give maxi-

mum productivity.

• Tool life reduces with an increase in axial depth of cut (a

p

).

Volume of material removed is less affected and running at

a

p

= 1 mm achieves 30% more volume removed as at 1.5 mm.

• Optimum parameters:

Insert GC1030 E-PM

0.2 mm/tooth feed rate

25 m/min cutting speed

1 mm axial depth of cut

Best toughness/security

Summary – Face milling using carbide inserts in HRSA materials

Insert S40T E-PL

0.2 mm/tooth feed rate

25 m/min cutting speed

1 mm axial depth of cut

Best productivity/tool life

Effect of material hardness

Small variations in material hardness will have a significant effect

on tool life.

Tool R300-063Q22-12H,

D

c

51 mm, f

z

0.24 mm/tooth, h

ex

0.18 mm,

a

p

2 mm, a

e

36 mm, v

c

30 m/min

Material: Inconel 718

min