Round insert geometries, Effect of feed, Effect of speed – Sandvik Coromant Heat resistant super alloys User Manual

Page 58

56

9

8

7

6

5

4

3

2

1

0

12

10

8

6

4

2

0

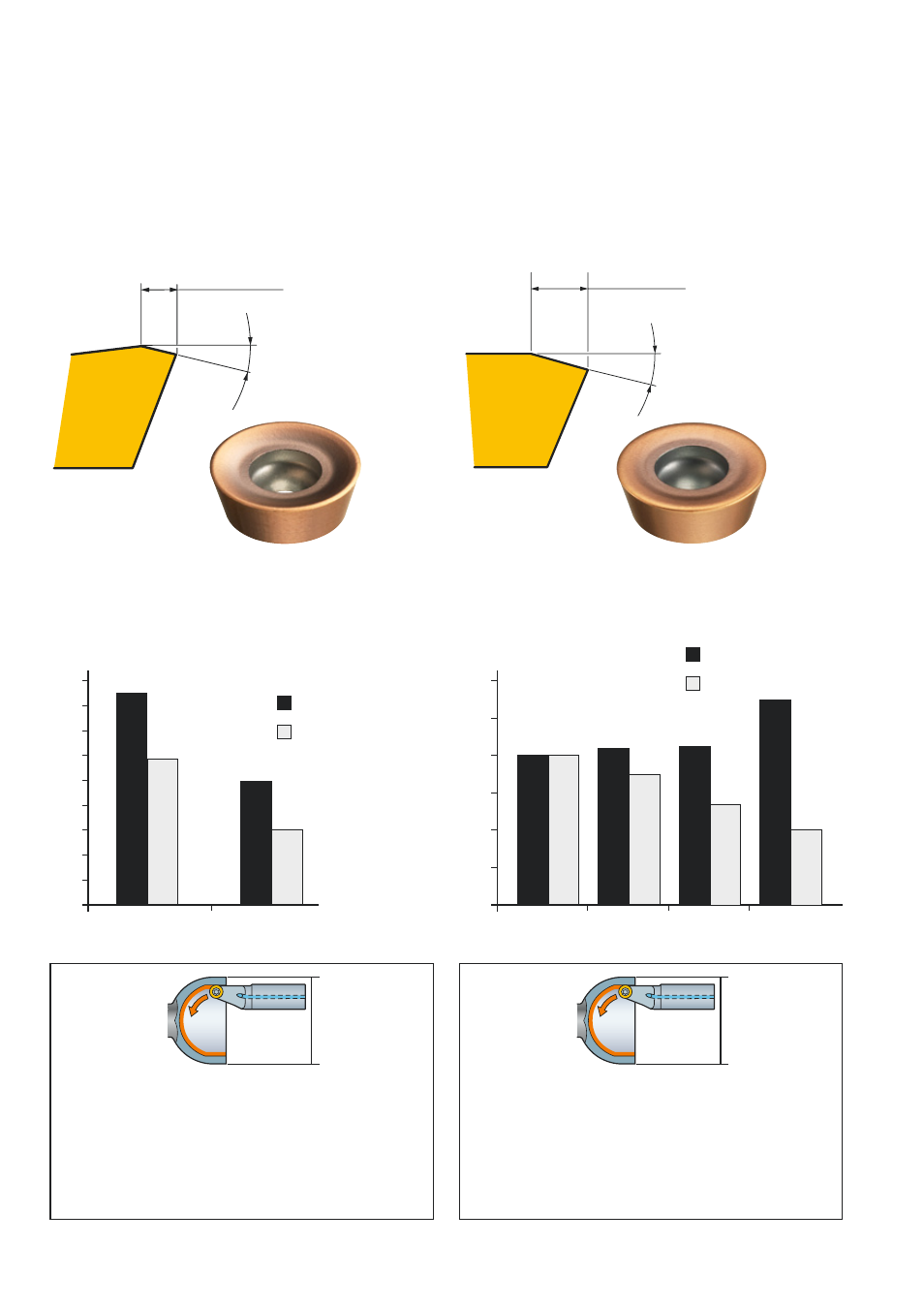

Round insert geometries

• R300-0828E-PL 1030 or 1010

• R300-1032E-PL 1030 or 1010

+ periphery ground.

+ light cutting.

+ low vibration/cutting forces

• R300-0828E-PH, 1030

• R300-1032E-PH, 1030

+ direct pressed.

+ need of stable fixture.

0.1 mm

15°

15°

0.2 mm

Time in cut, min

Feed, f

n

mm/r

0.1

0.15

Effect of feed

Facing to centre – Cobalt chromium

D

c

46 mm, v

c

70 m/min, a

p

0.5 mm, GC1030

Example:

At v

c

70 m/min, f

n

0.1 mm/r,

time per pass would be 29 sec.

At v

c

70 m/min, f

n

0.15 mm/r,

time per pass would be 20 sec.

D

m

46 mm

= R300-0828E-PL

= R300-0828M-PH

Time in cut, min

Speed, v

c

m/min

50

60

70

80

Effect of speed

Facing to centre – Cobalt chromium

D

c

46 mm, f

n

0.1 mm/r, a

p

0.5 mm, GC1030

Example:

At v

c

50 m/min, f

n

0.1 mm/r,

time per pass would be 41 sec.

At v

c

80 m/min, f

n

0.1 mm/r,

time per pass would be 25 sec.

D

m

46 mm

= R300-0828E-PL

= R300-0828M-PH