Insert shape selection, Entering angle – Sandvik Coromant Heat resistant super alloys User Manual

Page 15

13

CNMG

DNMG

SNMG

CNMX

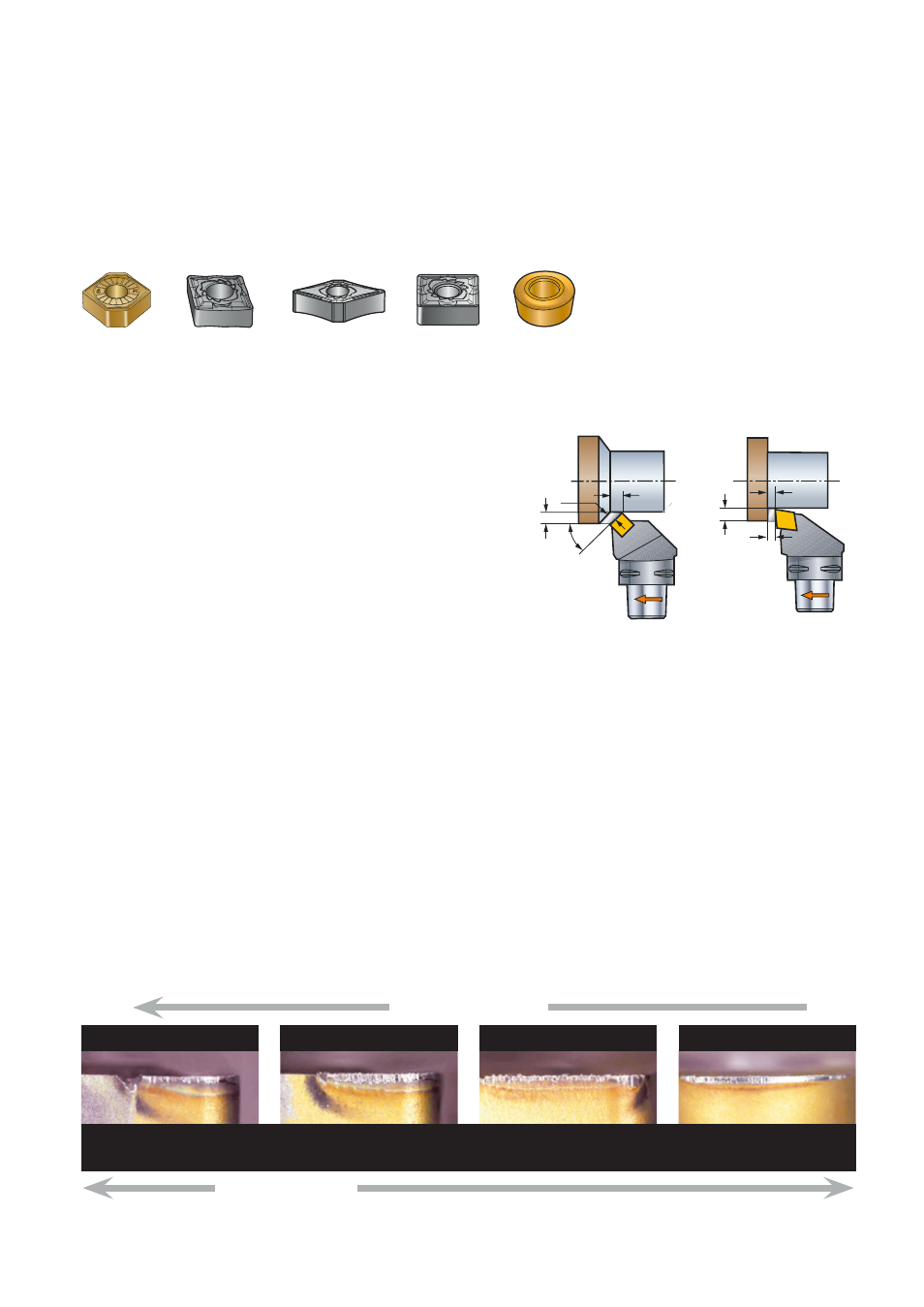

k

r

f

n

h

ex

≈ f

n

h

ex

h

ex

f

n

a

p

a

p

RCMT

h

ex

= f

n

x 0.71

Notch wear on the inserts is the major

problem when machining HRSA. The worst

notching occurs when the depth of cut is

greater than the nose radius, and the enter-

ing angle is 90°. (The depth of cut is the

influencing factor – with a depth of cut

smaller than the nose radius, the effective

entering angle is reduced even when the

angle on the insert itself is 90°).

By following some general rules the wear

can be controlled allowing more productive

grades to be used.

• Use as small entering angle as possible

(max 60°, min 25°)

– eg. SNMG, CNMX where

k

r

= 45°.

• Round inserts – use no greater entering

angle than 45° or 0.15 x diameter.

• Ramping – program a varying depth of cut

into the cutting operation. This spreads

the notching over the whole cutting edge,

giving longer tool life and more predict-

able wear. This method is used predomi-

nantly with ceramics, and mainly with

round inserts.

Insert shape selection

Entering angle –

k

r

With a standard C/D/SNMG style insert

for roughing, the entering angle is constant

regardless of depth of cut.

However, with round inserts the entering

angle varies from 0 to 90° depending upon

the ratio between depth of cut and diam-

eter.

Radial forces

High

Low

SNMG 45°

Round

Material: Inconel 718 (46 HRC) – a

p

2.0 mm, f

n

0.25 mm/rev, v

c

50 m/min – 5 min. time in cut

SNMG 75°

Notch

No notch

Effect of entering angle

Effect of entering angle on wear mechanism

h

ex

= chip thickness

CNMG 95°