Circular interpolation of existing holes, Circular interpolation of existing holes 108, Circular milling of existing hole – Sandvik Coromant Heat resistant super alloys User Manual

Page 110: The radial engagement ( a, Allowing for stability use d, 4 x d, And reduce feed by 50% of normal

108

5%

10%

15%

20%

25%

20%

40%

60%

80%

10

9

8

7

6

5

4

3

2

1

0

f

z

=

f

z

sinθ

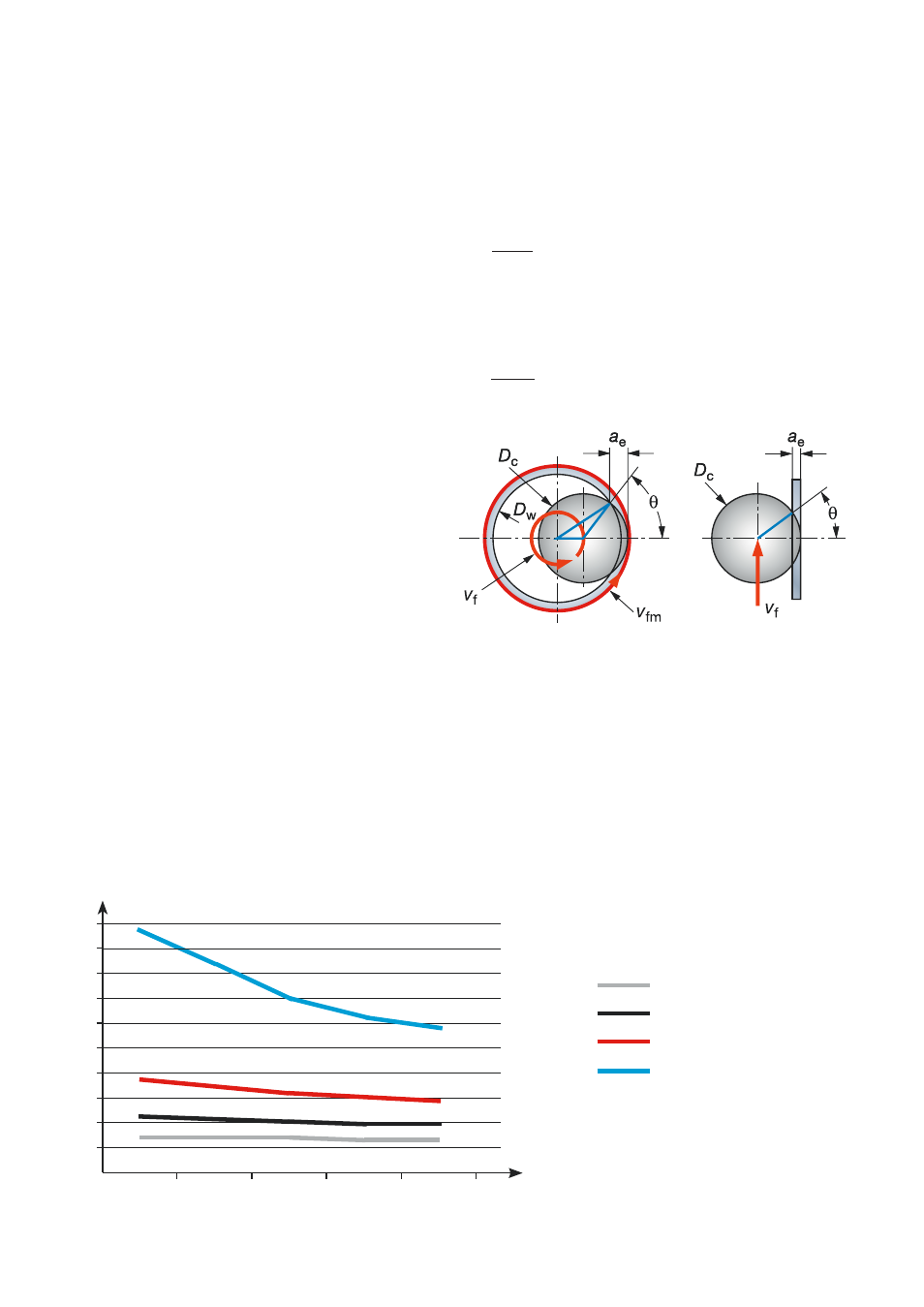

Hole diameters can be finish machined

using circular milling as an alternative to

boring depending on the surface finish

requirement. The feed rate (v

f

) must be

reduced compared to straight line milling

due to that in internal applications.

•

The periphery of the tool will be moving

faster than the centre line of the tool.

Programming of the feed rate (mm/min)

on most milling machines/CAM systems

is based on the centre line of the spin-

dle.

•

The radial engagement (a

e

) increases

compared to that of a straight cut

increasing the chip thickness, h

ex

.

•

The effect of both of these factors is

increased with the increase in cutter dia-

meter relative to the hole size.

•

The correct feed reduction compared to

straight cutting can be selected from the

diagram.

•

Allowing for stability use D

c

= 0.4 x D

m

and reduce feed by 50% of normal.

Tool centre feed reduction factor for given cutter dia.

hole dia. ratio (D

c

/D

m

) and constant chip thickness.

v

fm

= n x f

z

x z

n

D

vf

D

m

v

f

=

x v

fm

Percentage

a

e

/D

c

Feed reduction factor

Circular milling of existing hole