Grade application areas, Cutting parameters – Sandvik Coromant Heat resistant super alloys User Manual

Page 25

23

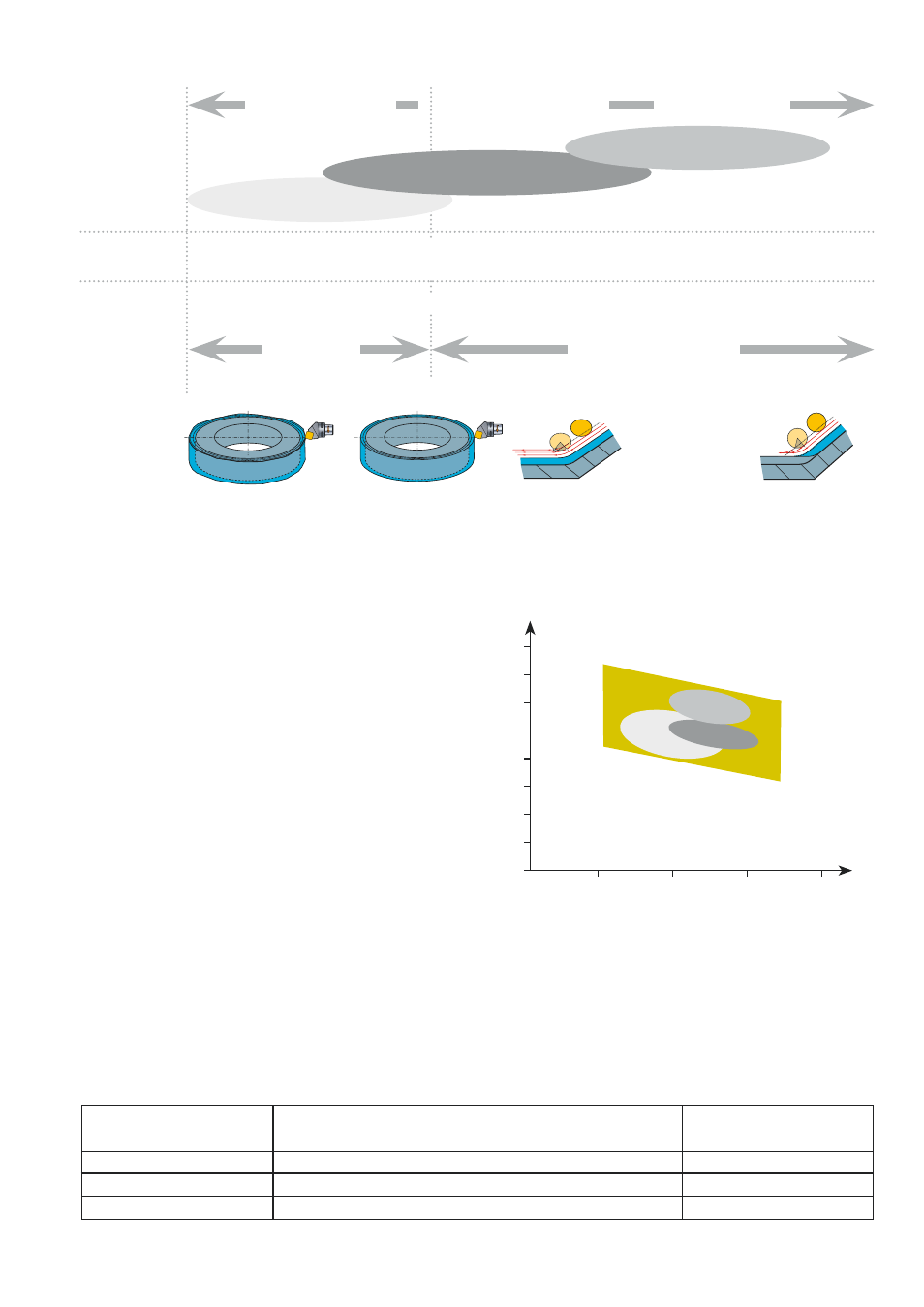

CC670

CC6065

CC6060

v

c

h

ex

CC6065

CC6060

CC670

Programming

consideration

Material

consideration

Bulk toughness

Grade application areas

Programmed direct

into corner/plunging

Programmed with roll-in,

roll-out of corner

Skin, scale, ovality

High quality forging

Pre-machined

material

Notch wear

resistance

First stage

machining

– 26 HRC

Intermediate stage

machining – 46 HRC

Cutting parameters

The speed should be balanced to create

enough heat in the cutting zone to plasti-

cise the chip but not too high to unbalance

the ceramic.

The feed should be selected to give a chip

thickness which is high enough to not work-

harden the material but not be too high to

cause edge frittering.

Higher feeds and depths of cut require a

reduction of the cutting speed.

These boundaries will change depending

upon the component material hardness and

grain size.

Short tool life

– too high

cutting temperature

Edge line frittering

– too

low cutting

temperature

W

or

k

hardening

of

wor

kpiece

material

Top

slice

–

high

cutting

pressure

CC670

200 to 300 m/min

2 mm

0.1 to 0.15 mm/r

CC6065

200 to 250 m/min

2 mm

0.15 to 0.2 mm/r

CC6060

250 to 300 m/min

2 to 3 mm

0.15 to 0.2 mm/r

Grade

Cutting speed, v

c

Cutting depth, a

p

Feed, f

n

Start cutting data recommendations (RNGN 12, RCGX 12) – Inconel 718 (38 to 46 HRC)

400

300

200

100

0

0.05

0.1

0.15

0.2